How to make a manual machine for making mesh netting

In the household, this traditional material is used for fencing, erecting fences, making cages, enclosures, sieves for sifting bulk materials, etc.

To reduce costs, instead of purchasing a ready-made Chainlink mesh, it can be made on a manual machine, which is not difficult to make, since its design is not complicated and does not require expensive materials.

We don't have to buy almost anything to make the machine. Everything you need for this can be found among the metal trash, which is no longer suitable for anything. In particular, we must prepare:

To prepare the parts and assemble the machine, we will need: a vice, an angle grinder, a welding machine and pliers.

In accordance with the dimensions of the bearing, at one end of the metal plate, using a grinder, we make two stepped cutouts, the larger of which should fit into the hole in the inner ring of the ball bearing.

We insert the plate with the cutout into the bearing and weld it in a vertical position to the inner ring.

We put a gear with a handle for rotation on the part of the metal strip protruding from the bearing and weld it, ensuring a permanent connection of these parts.

After completing the welding work, we make sure that the outer ring of the bearing is not stuck by welding and rotates freely.

We glue colored tape or electrical tape along its entire length to the outer surface of a piece of round metal pipe along a helical line with a predetermined step. Using the adhesive tape as a template, we cut a spiral slot in the pipe using a grinder.

We weld it to the bearing.

We weld two square-section rods from the outside to the pipe in the longitudinal direction, placing them opposite to each other.

We clamp one of the rods in a vice and insert a wire into the beginning of the slot on the pipe, the end of which is bent from the opposite side with pliers so that the bend clasps the second rod when the gear rotates.

We continue to rotate the handle and feed the wire into the machine.

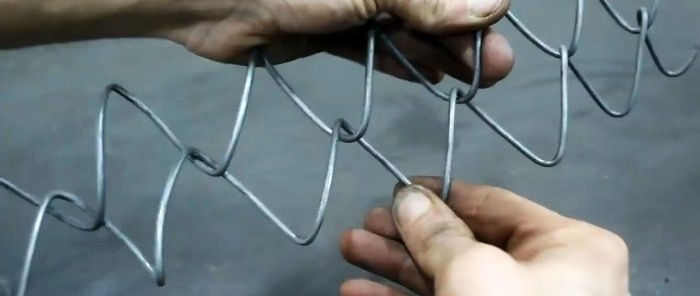

On the other hand, a twisted element of the Chainlink mesh will come out.

When its length reaches the desired size, cut the wire with pliers and begin winding the second element, etc.

Then, twisting the twisted elements in pairs, we obtain a Chainlink mesh of the required width and height.

To reduce costs, instead of purchasing a ready-made Chainlink mesh, it can be made on a manual machine, which is not difficult to make, since its design is not complicated and does not require expensive materials.

Will need

We don't have to buy almost anything to make the machine. Everything you need for this can be found among the metal trash, which is no longer suitable for anything. In particular, we must prepare:

- a small piece of metal strip;

- used ball bearing;

- gear wheel with handle for rotation;

- a piece of metal pipe;

- colored tape or electrical tape;

- two square rods;

- wire of the required diameter.

To prepare the parts and assemble the machine, we will need: a vice, an angle grinder, a welding machine and pliers.

The process of making a machine and knitting mesh Chainlink

In accordance with the dimensions of the bearing, at one end of the metal plate, using a grinder, we make two stepped cutouts, the larger of which should fit into the hole in the inner ring of the ball bearing.

We insert the plate with the cutout into the bearing and weld it in a vertical position to the inner ring.

We put a gear with a handle for rotation on the part of the metal strip protruding from the bearing and weld it, ensuring a permanent connection of these parts.

After completing the welding work, we make sure that the outer ring of the bearing is not stuck by welding and rotates freely.

We glue colored tape or electrical tape along its entire length to the outer surface of a piece of round metal pipe along a helical line with a predetermined step. Using the adhesive tape as a template, we cut a spiral slot in the pipe using a grinder.

We weld it to the bearing.

We weld two square-section rods from the outside to the pipe in the longitudinal direction, placing them opposite to each other.

We clamp one of the rods in a vice and insert a wire into the beginning of the slot on the pipe, the end of which is bent from the opposite side with pliers so that the bend clasps the second rod when the gear rotates.

We continue to rotate the handle and feed the wire into the machine.

On the other hand, a twisted element of the Chainlink mesh will come out.

When its length reaches the desired size, cut the wire with pliers and begin winding the second element, etc.

Then, twisting the twisted elements in pairs, we obtain a Chainlink mesh of the required width and height.

Watch the video

Similar master classes

Particularly interesting

Comments (1)