Plastic pipe drilling machine

This machine design is for those who want to quickly make a small drilling machine, but do not have the desire or ability to work with iron.

A drilling machine made of plastic pipes has a number of advantages compared to a machine made of iron:

It is inferior to iron only in load capacity, although it is strong enough for drilling small parts.

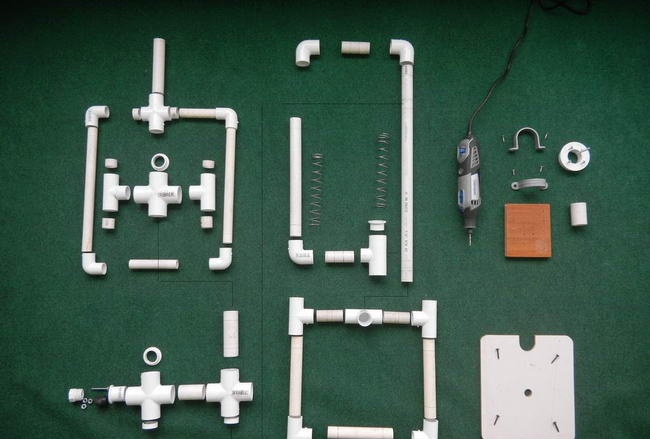

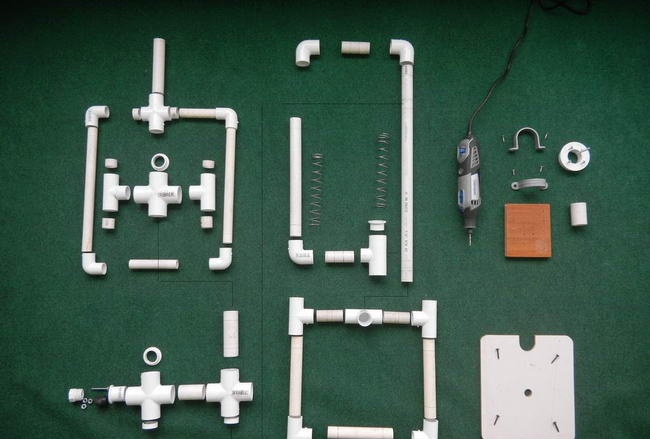

Pictured are the parts you will need. Almost all of them can be purchased at plumbing and hardware stores.

Please note that in addition to the plastic parts, the design also contains two wooden ones. This is the base of the frame and the mounting base for the drill itself.

The parts are as they will be soldered.

What pipe diameter should I use? - You decide. It all depends on the size of your drill. I took the diameter 25 mm.

Let's start assembling the drilling machine.

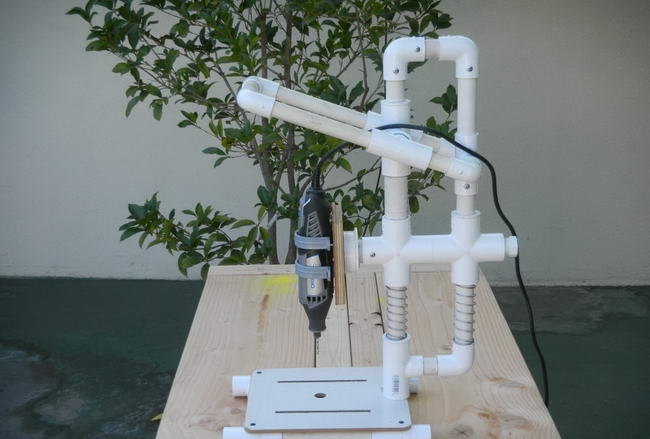

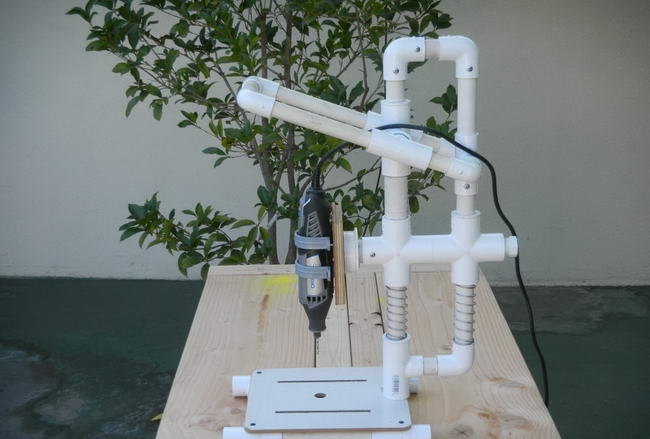

A movable unit that is attached to the lowering and raising handles. The middle crosspiece is larger in diameter so that it moves smoothly along the pipe. She doesn't get drunk, she just gets ready. Next, we solder the central unit on which the drill will be attached.The crosspieces are taken of the same diameter as the tubes on which it will ride. You cannot take it with a larger diameter - there will be too much play, and in order for it to move along the pipe without problems, the pipe must be ground down with sandpaper.

Springs have been purchased. You can try to find similar springs in an old mattress.

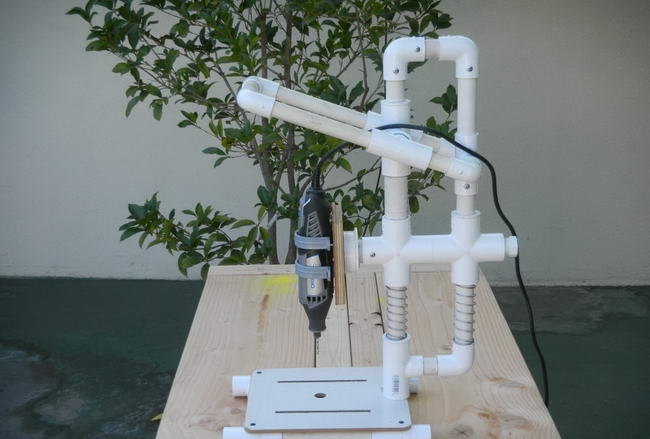

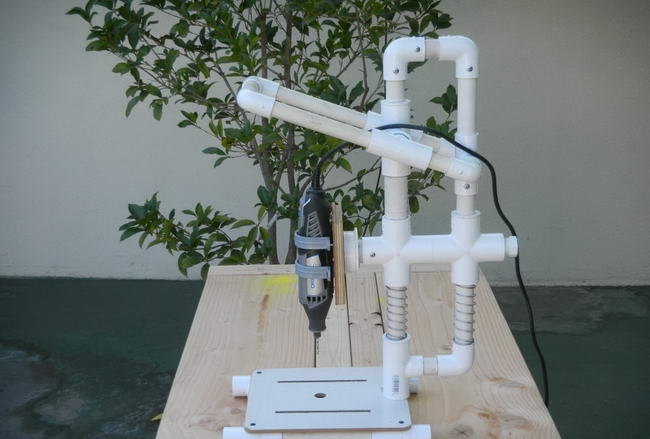

The machine is ready. The base is wooden, pre-cut and painted. In the center there is a hole for the free movement of the drill.

The drill is secured with plastic clamps. You can also use a drill with a pistol grip, after holding the trigger.

When soldering the machine, be especially careful: use gloves to avoid getting burned.

This is the small machine I came up with, which is well suited for drilling electronic circuit boards and small metal or plastic products.

In general, it will definitely be used in everyday life.

A drilling machine made of plastic pipes has a number of advantages compared to a machine made of iron:

- Easy to make.

- Easy.

- Easily repeatable without any drawings.

It is inferior to iron only in load capacity, although it is strong enough for drilling small parts.

Pictured are the parts you will need. Almost all of them can be purchased at plumbing and hardware stores.

Please note that in addition to the plastic parts, the design also contains two wooden ones. This is the base of the frame and the mounting base for the drill itself.

The parts are as they will be soldered.

What pipe diameter should I use? - You decide. It all depends on the size of your drill. I took the diameter 25 mm.

Let's start assembling the drilling machine.

A movable unit that is attached to the lowering and raising handles. The middle crosspiece is larger in diameter so that it moves smoothly along the pipe. She doesn't get drunk, she just gets ready. Next, we solder the central unit on which the drill will be attached.The crosspieces are taken of the same diameter as the tubes on which it will ride. You cannot take it with a larger diameter - there will be too much play, and in order for it to move along the pipe without problems, the pipe must be ground down with sandpaper.

We assemble the entire structure with the base of the machine.

Springs have been purchased. You can try to find similar springs in an old mattress.

Drill assembly.

The machine is ready. The base is wooden, pre-cut and painted. In the center there is a hole for the free movement of the drill.

The drill is secured with plastic clamps. You can also use a drill with a pistol grip, after holding the trigger.

When soldering the machine, be especially careful: use gloves to avoid getting burned.

This is the small machine I came up with, which is well suited for drilling electronic circuit boards and small metal or plastic products.

In general, it will definitely be used in everyday life.

Similar master classes

Particularly interesting

Comments (8)