How to bend a profile pipe at any angle

When it is necessary to make an element with an angle of 45 degrees from a profile pipe, then usually two blanks are butted at 22.5 degrees, after which they are welded together. This is a very simple and fast method, but not the most beautiful. In the case when you need to make a smooth bend in a solid pipe without forming a sharp outer corner, you can use the following method.

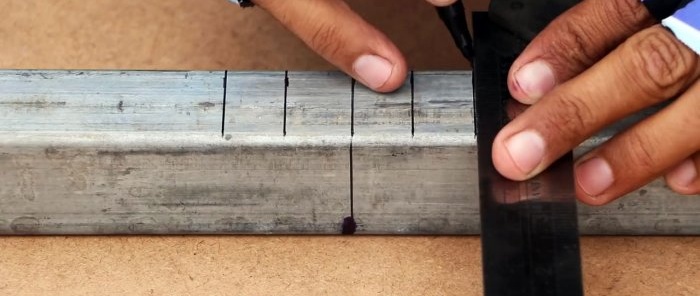

In the center of the future bend of the profile pipe, a transverse line is drawn with a marker under the square. This mark is made on all 4 sides of the pipe.

Next, on one of the sides you need to make 4 more transverse lines, 2 to the left and to the right of the central one. They are held under the square with an indentation of half the cross-section of the pipe. For example, if it is 40x40 mm, then you should retreat in increments of 20 mm, and if it is 50x50 mm, then 25 mm. The same lines must be applied on the opposite side of the pipe.

Then diagonals are drawn between these lines, as in the photo. As a result, they should form the letter “M”.Similar diagonals are made on the opposite side of the pipe. It is important that they are in the same direction.

Next, the pipe is turned so that the sides with diagonals are on the sides, after which you should draw the extreme lines with a marker, both on the top side and the back.

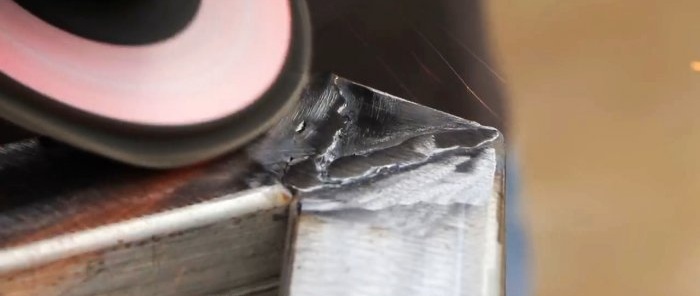

Now, using a grinder, you need to make diagonal cuts on both sides. It is most convenient to use a worn cutting wheel for this, since it has a small diameter, which allows you to work thinly without cutting off excess.

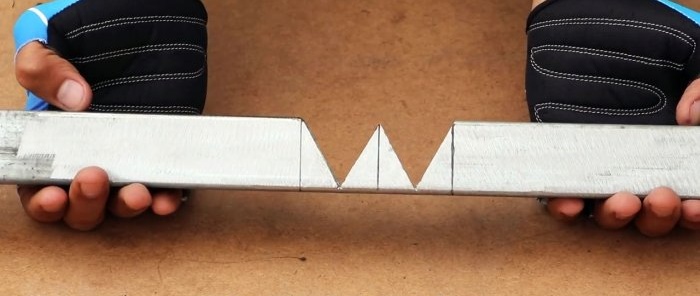

After cutting the diagonals, you need to lay the pipe so that the shape or letter “M” is upside down. At the next stage, the outermost marks located on top are cut, while the turn of the pipe should remain intact. As a result of trimming, an unnecessary fragment with two teeth is separated.

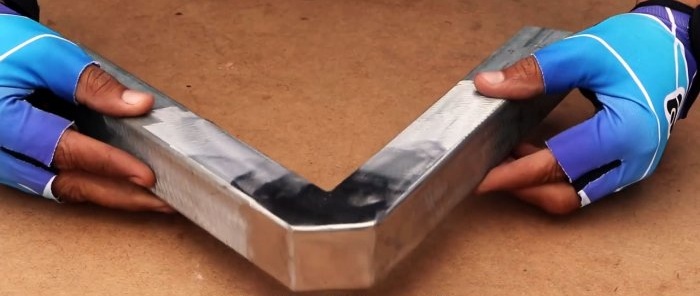

The pipe prepared in this way is bent by hand.

If its walls are thick, you will have to use a vice. Next you need to weld and sand the joints.

The result is a perfect 45 degree curve with no sharp outer corner that looks factory. In this way, pipes can be bent in the manufacture of various frames and frames where safety is important. An accidental collision with a hand or foot on such a bend is less dangerous than on a regular bend with a sharp outer corner.

Required tools:

- roulette;

- square;

- marker;

- Bulgarian;

- welding machine.

Bending a profile pipe at 45 degrees

In the center of the future bend of the profile pipe, a transverse line is drawn with a marker under the square. This mark is made on all 4 sides of the pipe.

Next, on one of the sides you need to make 4 more transverse lines, 2 to the left and to the right of the central one. They are held under the square with an indentation of half the cross-section of the pipe. For example, if it is 40x40 mm, then you should retreat in increments of 20 mm, and if it is 50x50 mm, then 25 mm. The same lines must be applied on the opposite side of the pipe.

Then diagonals are drawn between these lines, as in the photo. As a result, they should form the letter “M”.Similar diagonals are made on the opposite side of the pipe. It is important that they are in the same direction.

Next, the pipe is turned so that the sides with diagonals are on the sides, after which you should draw the extreme lines with a marker, both on the top side and the back.

Now, using a grinder, you need to make diagonal cuts on both sides. It is most convenient to use a worn cutting wheel for this, since it has a small diameter, which allows you to work thinly without cutting off excess.

After cutting the diagonals, you need to lay the pipe so that the shape or letter “M” is upside down. At the next stage, the outermost marks located on top are cut, while the turn of the pipe should remain intact. As a result of trimming, an unnecessary fragment with two teeth is separated.

The pipe prepared in this way is bent by hand.

If its walls are thick, you will have to use a vice. Next you need to weld and sand the joints.

The result is a perfect 45 degree curve with no sharp outer corner that looks factory. In this way, pipes can be bent in the manufacture of various frames and frames where safety is important. An accidental collision with a hand or foot on such a bend is less dangerous than on a regular bend with a sharp outer corner.

Watch the video

Similar master classes

Particularly interesting

Comments (1)