How to make a 90 degree pipe saddle

Sometimes, in a country house, garage or home, it is necessary to weld two pipes so that the end part of one fits tightly, without gaps, to the cylindrical generatrix of the other. Only in this case the connection by welding or soldering will be strong and airtight.

In production, such an operation is performed with a milling cutter on a machine.

There is a simple method at home that allows you to solve this problem with good quality, with a minimum set of equipment.

Preparation

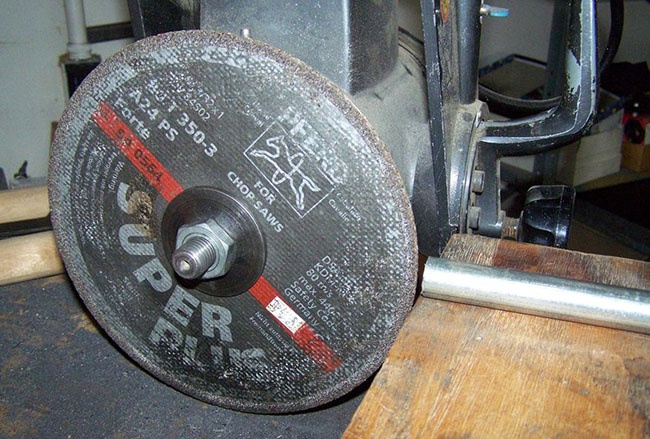

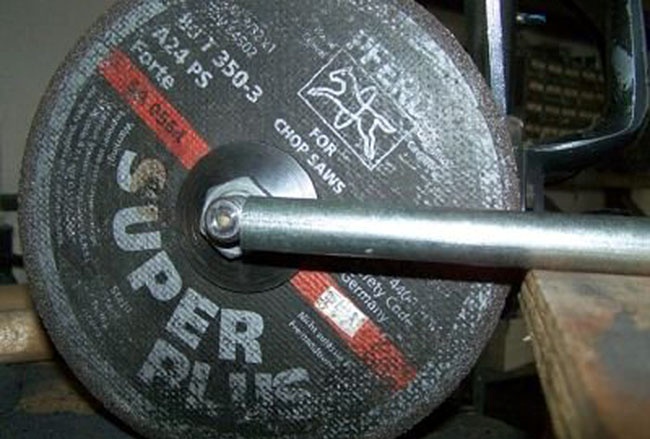

We will use a cutting wheel mounted in a cantilever on the electric motor shaft or an angle grinder securely mounted on a workbench.

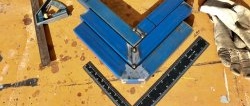

Let's install the work table so that its plane is parallel to the axis on which the cutting disc rotates.

Let's move the work table down in height by half the outer diameter of the pipe being processed. This way we will achieve symmetrical processing of the end.

End profile marking

For convenience, wrap the end of the pipe with white paper masking tape.

We draw a cutting profile on its surface with a black marker or pencil.

Ideally, it should correspond to the cylindrical generatrix of the mating part of the tube.

Absolute marking accuracy is not required. The required profile will be obtained during subsequent processing.

Treatment

We place the part on the table surface, start the disk motor, and begin to remove excess metal from the end surface, focusing on the markings.

Hold the piece tightly, don’t let it roll around the table!

Work slowly, remove the metal in several stages, as carefully as possible.

Fit

Let's check the resulting profile by attaching it to the generatrix of the second pipe.

The gaps are still large. No problem, continue adjusting. Gradually, the profile will fit tightly to the surface of the second pipe, with minimal gaps.

Finish

The result turned out very good, the gaps are minimal, now you can weld or solder.

The method is not suitable for mass production due to its high labor intensity, but for the needs of personal farming it is optimal.

Having gained experience, trained your eye, and trained your hand, you can learn how to process pipe ends with connections other than 90 degrees.

Important safety precautions!

It is advisable that the disc have a protective cover; it is installed initially on angle grinders.

Eyes and face should be protected with goggles, or better yet, with a transparent mask. The whole world has been working in them for a long time!

You need to wear gloves on your hands, preferably split leather. Good luck in job!

https://home.washerhouse.com

Original article in English

Similar master classes

Particularly interesting

Comments (0)