Scooter with a chainsaw engine and an angle grinder gearbox

Recently, individual electric vehicles have become increasingly popular, but it is too early to write off the internal combustion engine. For a homemade scooter, it is quite possible to use a motor from a chainsaw, the power of which is quite sufficient to ensure the dynamic movement of this simple device. Looking ahead, I will say that during testing the roller skate reached a speed of up to 40 km/h, and in cruising mode it steadily maintained 20 km/h.

Materials and tools

- gasoline engine from a chain saw;

- gearbox with metal gears from a powerful grinder;

- profile steel pipe of square section;

- drive wheel with bearing and inner bushing;

- bicycle fork with wheel;

- round steel tube;

- paint in a can or regular paint with a brush;

- steel and aluminum sheets.

Tool: electric welding; angle grinder; drill press or drill; wrenches and pliers.

Scooter manufacturing process

Remove the guide and drive gear of the cutting chain from the chainsaw.

We mark the pipe for the scooter frame and cut it according to the marks using a grinder.

In the back of the profile tube we drill holes for the rear wheel axle.

We lay out the scooter frame on a workbench, tighten it with a clamp and weld the joints.

We make the steering column by welding the finished bicycle part to the extension tube.

We try on the front assembly of the front wheel to the frame in place and attach it with electric welding.

We extend the steering wheel by welding a piece of half-inch pipe to it.

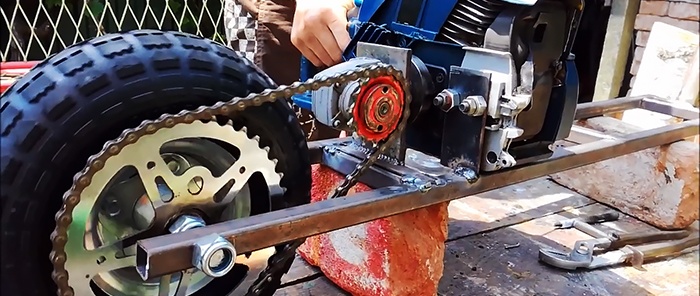

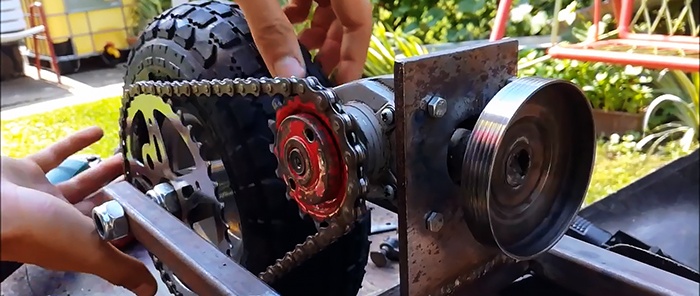

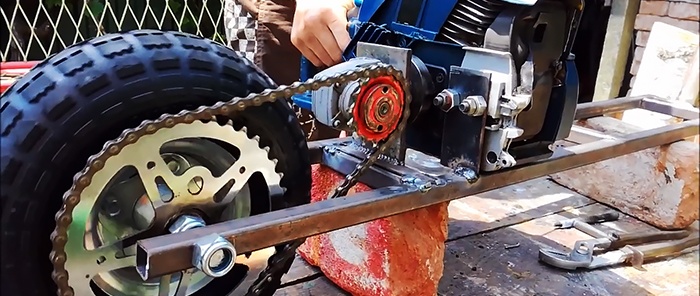

Using electric welding, we mount a large diameter driven gear on the rear wheel hub.

We install the rear wheel on the frame, making a fixed axle for it from a steel pin of a suitable diameter.

The frame with wheels is ready.

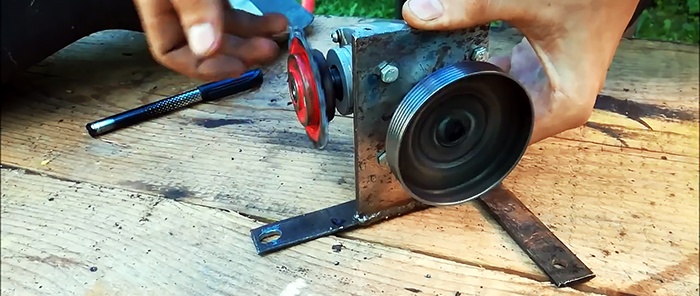

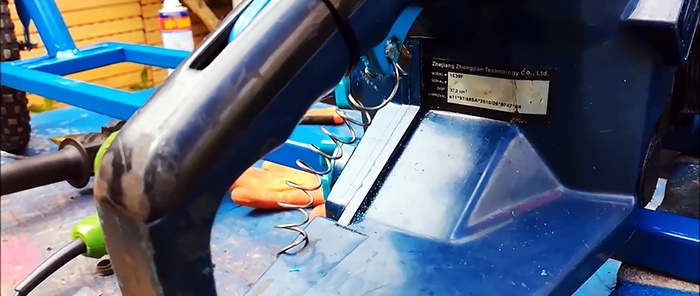

We make a bracket for the gearbox from a steel plate and two metal strips. On its axis, on one side, we mount the drive gear and the outer part of the chainsaw clutch.

We put a chain on the gears and install the engine.

We paint the frame and steering wheel using spray cans or a brush.

We install the gas cable, which should act on the chainsaw control key and the return spring.

We cut out a support platform for the leg from aluminum and fasten it with rivets. The scooter is ready for testing and you can use it on the big road.

During work on its manufacture, you must be careful and be sure to use a welder’s protective mask and goggles to protect your eyes from sparks when cutting metal with a grinder.

Watch the video

Similar master classes

Particularly interesting

Comments (2)