Sharpening a chainsaw chain using a drill

The cutting edges of gasoline or electric saw chains become dull over time. A dull saw will lose performance and overload the drive motor. Of course, you can contact a specialized service center that sharpens chains. But I think there will be many people who will want to try to do it themselves.

Today I will tell you how to sharpen the cutting teeth of a saw chain yourself. To perform this work, we do not need expensive specialized tools or special professional skills.

What do we need

The main tool we will use is a round file (not a conical one!). The cross-sectional diameter of the file must correspond to the rounding diameter of the cutting tooth of the chain. Files with a diameter of 4.8 mm are suitable for sharpening most household saws. Check this size with your saw and select the appropriate file.

Chainsaw teeth are often sharpened by hand with a file. I propose to improve and speed up this process, so we will need a screwdriver or drill, preferably with adjustable speed.

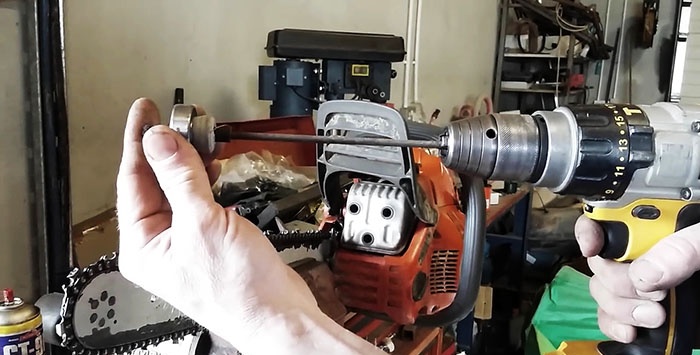

Well, the highlight of my sharpening technology is a small bearing. It can be anything - ball, roller, cylindrical, conical. The main thing is that it is comfortable to hold in your hand by the outer clip. I will explain its purpose below.

Tool preparation

First of all, we remove the shank, that is, the part of the file that fits into the handle. This can be done using sandpaper or a grinder, whichever is more convenient for you. After this, insert the file into the chuck of a drill or screwdriver and clamp it.

Next, we make a sleeve from wood, plastic or any other material that fits tightly onto the free end of the file. The inner race of our bearing should fit tightly onto the outer surface of the bushing.

This is done so that during operation you can hold the tool with two hands - one by the drill handle, the other by the outer race of the bearing.

Sharpening

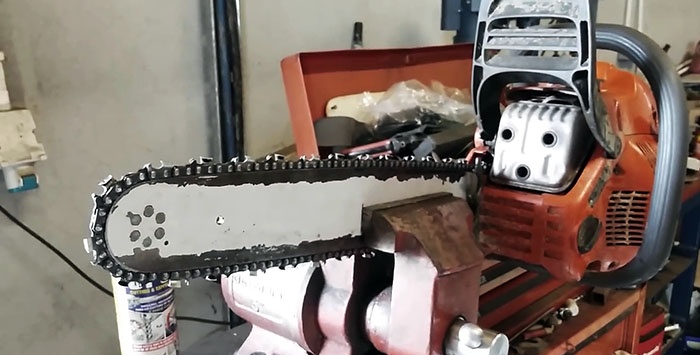

We place the saw on a flat horizontal surface, or better yet, clamp its bar in a vice, as I did. We will sharpen the teeth of the upper part of the chain, so the chain should move freely along the bar.

We mark the tooth from which we will begin sharpening. This can be done with a marker or by sticking a piece of adhesive tape on it. So, let's get down to the main part of the work.

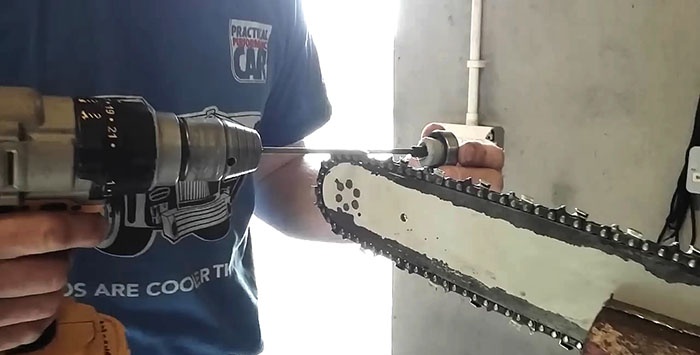

We place the file in the rounding of the cutting edge of the tooth and orient it strictly in accordance with the required sharpening angle. This is the most important point. Sharpening should occur at an angle of 30 degrees to the chain bar. There are usually special marks on the outside of the chain teeth that indicate the correct angle. When performing work, the file should be kept parallel to the mark.

So, having installed the file in the required manner and holding our tool with both hands (as described above), turn on the drill and lightly press the file against the tooth being sharpened. It is enough to spend 1 – 2 seconds on each tooth. We pass in this way along the entire chain, gradually moving it along the bus.

That's all!

Warning

Once again I would like to remind you of the importance of maintaining the correct sharpening angle. During sharpening, the file should not “walk” in a horizontal or vertical plane. It was for this purpose that I adapted the bearing as a second support for the file.

Good luck to all!

Watch the video

Be sure to watch the detailed and visual video on sharpening.