How to make a soldering iron from a regular soldering iron

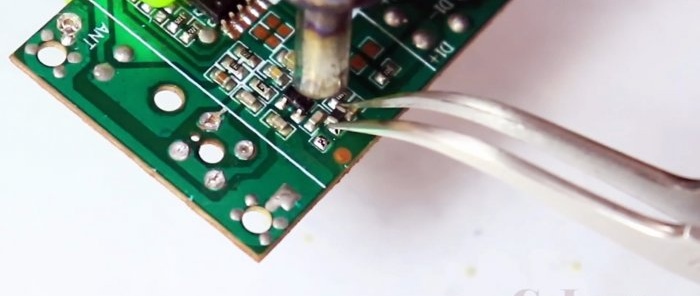

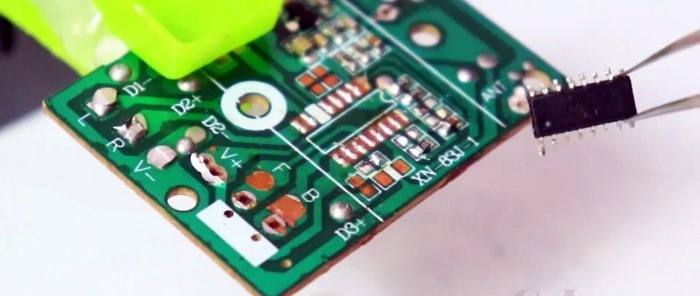

When soldering miniature and complex microcircuits, it is difficult to do without a hot air gun. It does not involve direct contact with the solder, like a regular soldering iron, but melts it remotely by blowing hot air. They can easily and quickly solder in places that are hard to reach. If you don’t have this tool, you can make it yourself using a regular electric soldering iron.

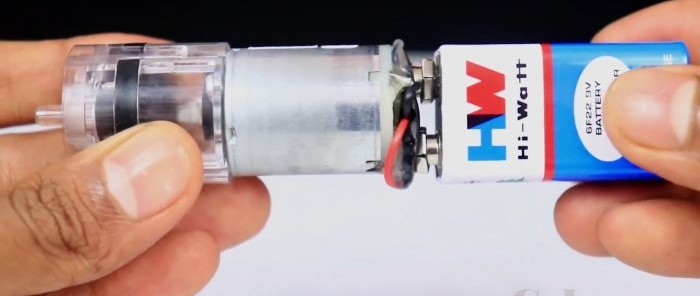

You can use a cheap Chinese micro compressor as an air blower for a homemade hot air gun. It runs from the crown. To connect the compressor to the battery, a connector under the crown is soldered to its contacts.

After soldering, the connector is glued with hot glue to the motor from the back. The crown itself will be held on the connector without additional fixation.

Then the electric soldering iron is finalized.

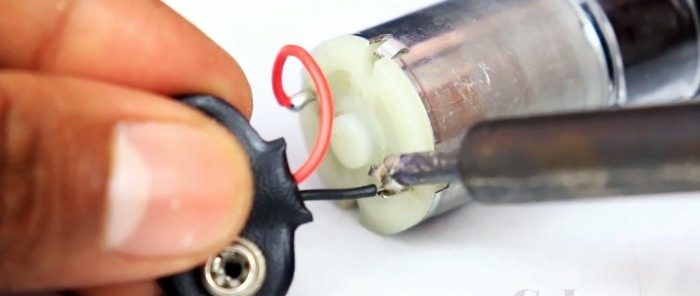

There is a gap at the junction of its heating tube and the handle that needs to be removed. To do this, the handle is unscrewed and the protrusions on it are cut off. This will allow the tube to fit snugly.

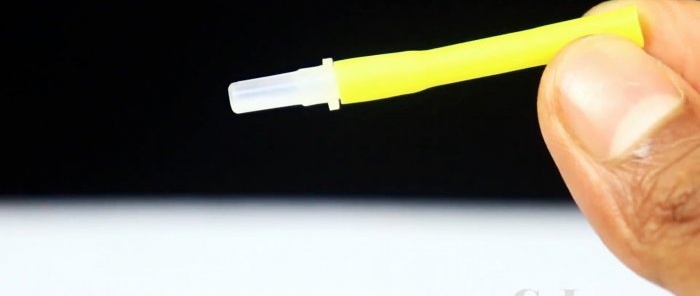

Also, a hole is drilled on the side of the handle to match the diameter of the existing thin hose. After this, the soldering iron is put back together.

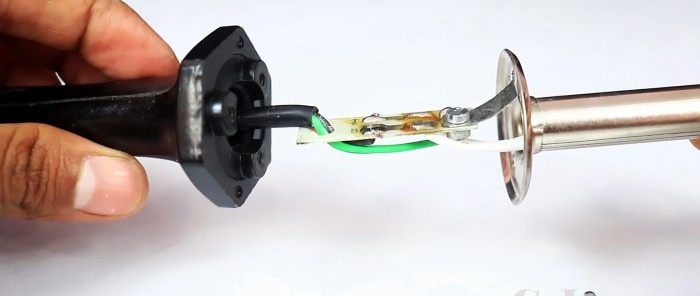

Next, you need to glue a small piece of hose into the hole on the handle.

Then the compressor is glued to the handle with hot glue, and a hose is connected to it. To ensure tightness, immediately close the back of the soldering iron, where the wire enters, with glue.

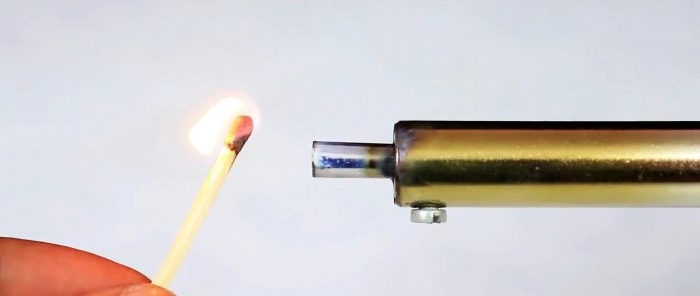

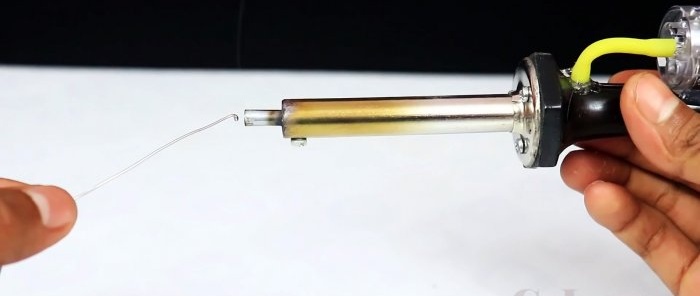

The soldering iron tip is removed and a thin metal tube of the same diameter is installed instead. Now, when you turn on the heating of the soldering iron and connect the crown to the compressor, hot air will come out of the tube. Its flow rate and temperature are sufficient to melt solder.

In the future, if you need to use your homemade product as a regular soldering iron, instead of the tube, you can reinstall the tip. In this case, the compressor no longer turns on. The performance of a homemade hot air gun is sufficient to solve all the problems of the average user. Considering the manufacturing cost, the device can be recommended when performing independent repairs of electronics and household appliances in order to eliminate the cost of a specialized, more expensive tool.

Materials:

- electric soldering iron;

- microcompressor -

- crown connector;

- crown;

- thin hose (can be from a medical drip system);

- metal tube.

Hot air gun manufacturing process

You can use a cheap Chinese micro compressor as an air blower for a homemade hot air gun. It runs from the crown. To connect the compressor to the battery, a connector under the crown is soldered to its contacts.

After soldering, the connector is glued with hot glue to the motor from the back. The crown itself will be held on the connector without additional fixation.

Then the electric soldering iron is finalized.

There is a gap at the junction of its heating tube and the handle that needs to be removed. To do this, the handle is unscrewed and the protrusions on it are cut off. This will allow the tube to fit snugly.

Also, a hole is drilled on the side of the handle to match the diameter of the existing thin hose. After this, the soldering iron is put back together.

Next, you need to glue a small piece of hose into the hole on the handle.

Then the compressor is glued to the handle with hot glue, and a hose is connected to it. To ensure tightness, immediately close the back of the soldering iron, where the wire enters, with glue.

The soldering iron tip is removed and a thin metal tube of the same diameter is installed instead. Now, when you turn on the heating of the soldering iron and connect the crown to the compressor, hot air will come out of the tube. Its flow rate and temperature are sufficient to melt solder.

In the future, if you need to use your homemade product as a regular soldering iron, instead of the tube, you can reinstall the tip. In this case, the compressor no longer turns on. The performance of a homemade hot air gun is sufficient to solve all the problems of the average user. Considering the manufacturing cost, the device can be recommended when performing independent repairs of electronics and household appliances in order to eliminate the cost of a specialized, more expensive tool.

Watch the video

Similar master classes

How to quickly convert a soldering iron into a soldering iron

When there is no hot air gun or infrared soldering iron

Life hack: how to solder small parts with a soldering iron with a thick tip

The simplest temperature regulator for a soldering iron tip.

How to Make a Portable Battery-Powered Compressor

How to simply solder aluminum tightly with regular solder

Particularly interesting

Comments (0)