How to Make a Portable Battery-Powered Compressor

In this master class we will look at creating an electric pump for inflating the wheels of motorcycles and bicycles. The main advantages are that the pump is powered by a built-in battery and is small in size. Its design is such that anyone can make it. These advantages allow you to take it with you anywhere.

12 volt battery with charger, on/off button, battery connector. All with Ali Express, there are a huge number of different types to choose from. All you need is a soldering iron, a lighter, a heat gun, a knife or scissors and a screwdriver.

We start assembling with the pumps.We use 2 pumps for greater productivity, their number depends only on your imagination. We connect them with a tee. Due to the size, the tee does not fit directly, so we take silicone tubes and connect them using them. Before putting the tubes on the pumps, we warm them up with a lighter so that the tubes fit tightly and airtight. It’s easier with a tee - it has a quick-clamping mechanism.

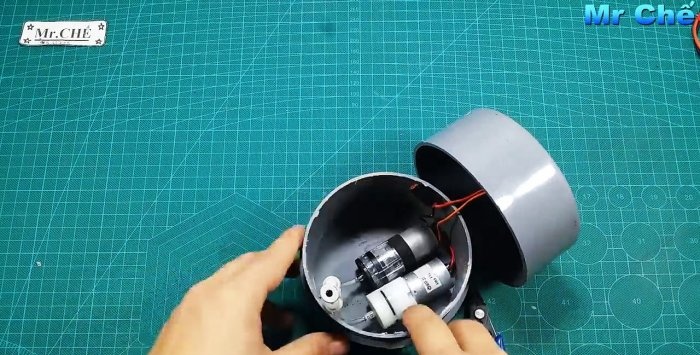

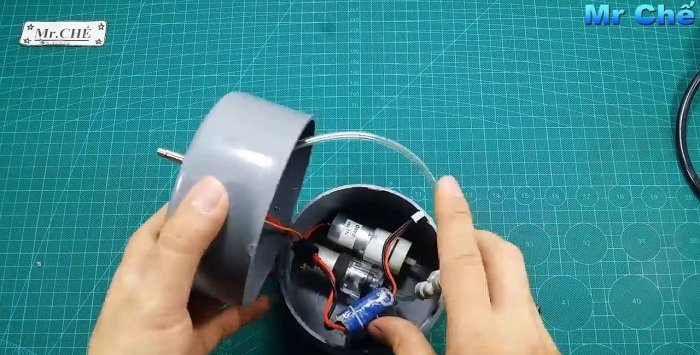

Next, we solder the pumps parallel to each other. We put a plug on a piece of sewer pipe, put the pump and battery inside, check that everything fits.

Then we solder wires and a connector for connecting the battery and power button to one of the pumps.

You can solder it to any pump, since they are connected in parallel and this will not change the essence. Now let's work on the second pipe plug. It is necessary to place the power button and the air valve of the bicycle inner tube on it. To do this, outline the button on it, drill it out and cut a hole.

It can be trimmed with a Dremel or a regular hand file.

With a valve it’s even easier - just drill a hole of the required diameter.

We glue the button with a glue gun, and fasten the valve with the supplied bolt and washer.

After this, solder the pumps to the button as shown.

We place the resulting structure in a pipe body and fix it with a glue gun.

We connect the air valve to the pump tee. We glue the connection between the valve and the hose with additional hot glue.

We connect the battery and assemble the case.

It is necessary to drill several holes in the top cover for air intake. We attach a hose from a bicycle pump to the valve outside. The build process is complete.

The resulting electric compressor easily copes with the task.

It works while you rest.Do not forget that the battery must be charged before the trip, otherwise an unpleasant surprise may await you on the road.

You will need:

- A piece of plastic sewer pipe and two plugs for it. Can be purchased at any plumbing store.

- Two 12 V air pumps. Took for Ali express.

- Hose from a bicycle pump. At the market or in bike shops.

- Valve for a bicycle tube (in common parlance – nipple). At the market or in bike shops.

- Air quick release tee.

- Silicone tube.

12 volt battery with charger, on/off button, battery connector. All with Ali Express, there are a huge number of different types to choose from. All you need is a soldering iron, a lighter, a heat gun, a knife or scissors and a screwdriver.

Manufacturing a compressor for inflating tires

We start assembling with the pumps.We use 2 pumps for greater productivity, their number depends only on your imagination. We connect them with a tee. Due to the size, the tee does not fit directly, so we take silicone tubes and connect them using them. Before putting the tubes on the pumps, we warm them up with a lighter so that the tubes fit tightly and airtight. It’s easier with a tee - it has a quick-clamping mechanism.

Next, we solder the pumps parallel to each other. We put a plug on a piece of sewer pipe, put the pump and battery inside, check that everything fits.

Then we solder wires and a connector for connecting the battery and power button to one of the pumps.

You can solder it to any pump, since they are connected in parallel and this will not change the essence. Now let's work on the second pipe plug. It is necessary to place the power button and the air valve of the bicycle inner tube on it. To do this, outline the button on it, drill it out and cut a hole.

It can be trimmed with a Dremel or a regular hand file.

With a valve it’s even easier - just drill a hole of the required diameter.

We glue the button with a glue gun, and fasten the valve with the supplied bolt and washer.

After this, solder the pumps to the button as shown.

We place the resulting structure in a pipe body and fix it with a glue gun.

We connect the air valve to the pump tee. We glue the connection between the valve and the hose with additional hot glue.

We connect the battery and assemble the case.

It is necessary to drill several holes in the top cover for air intake. We attach a hose from a bicycle pump to the valve outside. The build process is complete.

The resulting electric compressor easily copes with the task.

It works while you rest.Do not forget that the battery must be charged before the trip, otherwise an unpleasant surprise may await you on the road.

Watch the video

Similar master classes

Particularly interesting

Comments (2)