How to Make an Ultra-Compact, Amazingly Powerful Water Pump

Such a mini-pump can be useful when performing small jobs in a home workshop, when you need to pump something or wash small parts. Any adult can make it; all you need is care and attention.

Will need

Materials:

- medical syringe with a diameter of 11 mm;

- 3.7V mini DC motor and dimensions 4x8 mm;

- silicone glue;

- transparent plastic;

- lubricant;

- superglue for gluing plastic;

- flexible plastic tube.

Tools: gas torch, thin nail, compass, scissors, soldering iron, vice with jaw pads, knife, file, drill, jigsaw, sandpaper, etc.

The process of making an ultra-compact mini pump with amazing power

We take out the rod from the graduated cylinder of the syringe and remove the piston from it, which we try on the engine body.

We measure the internal diameter of the syringe cylinder (8.8 mm) and cut out a circle of the same size from transparent plastic according to a pre-prepared template.

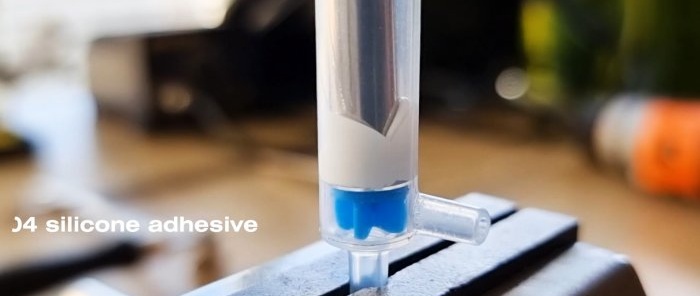

We solder the holes in the mini-motor housing, lubricate the end of the shaft with oil, fill the end of the motor with silicone glue and put a plastic circle on top.

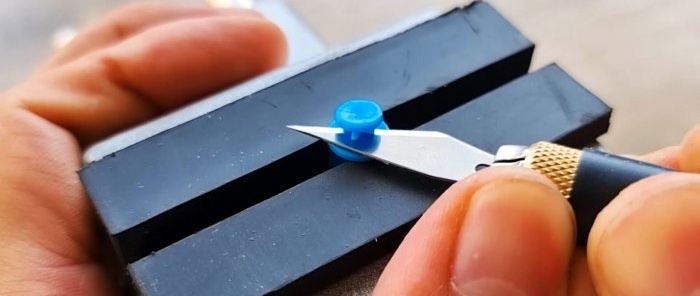

From the end on which the piston is fixed, we cut off a section 5 mm high, measured from the transverse stiffener. We grind the cross-section of the rod and make a small notch in the center.

We remove that part of the rod fragment to which the piston is attached, and drill a hole in the center. We put the resulting part on the mini-motor shaft and give it the shape inherent in the pump impeller.

We cut off a fragment with a cone from the syringe cylinder so that it can fit in it with a reserve mini motor with impeller. At the bottom side of the cylinder fragment we make a hole tangentially.

We cut off the conical part from the cylinder of the same syringe, make a semicircular recess at the larger end, sand it with sandpaper, apply superglue and glue it from the outside to the fragment of the syringe cylinder above the hole tangentially.

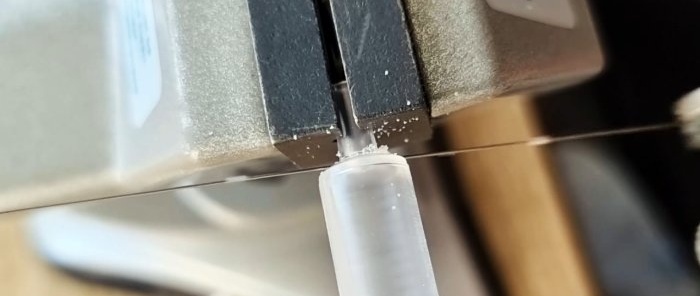

We lower the mini-engine into the cylinder fragment with the impeller forward. Using a needle, fill the annular gap between the bodies of the cylinder fragment and the mini-engine, as well as its end with silicone glue.

We cut off the inlet part of the syringe barrel, make a semicircular saddle, grind it and glue it to a fragment of the syringe barrel with a motor in the center.

Checking the pump. To do this, we put a plastic tube on the suction pipe, which we lower into a bottle of water. Fill the pump housing with liquid and turn on the pump. Its power is enough to supply a jet of 2.8 m. It is able to pump up to 1 liter of water per minute.