We make eternal anticorrosive for the arches and bottom

In order to once and for all protect the bottom and arches of the car from corrosion, it is necessary to treat them with a mixture of gun fat and polymer-bitumen mastic. This composition is easy to apply, holds securely, does not chip or wash off.

Materials:

- rust converter;

- degreaser or brake disc cleaner;

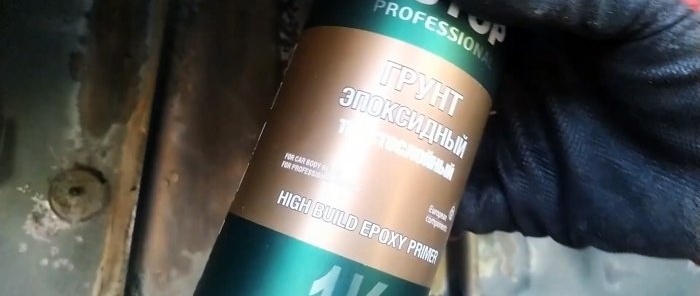

- epoxy primer;

- cannon fat;

- bitumen-polymer mastic.

Process of processing the bottom and arches

Surfaces that need to be treated with anti-corrosion are cleaned in places where corrosion occurs to bare metal.

It is advisable to completely remove all rust, so where it is impossible to reach with a power tool, use a screwdriver or a hand-held metal brush. Protected areas must be treated with a rust converter. It is convenient to apply with a spray.

After the converter is activated, its excess is wiped off, the surface is washed with clean water and dried. Next, the metal is degreased with a special degreaser or brake disc cleaner.

Once the degreaser has evaporated, the epoxy primer is applied. It sticks very well, so that's what you should use.To speed up the process, the epoxy primer can be dried with a hairdryer.

On the tile, gun fat and bitumen-polymer mastic are heated to normal fluidity, then they are mixed one to one. The mixture must continue to be heated until it reaches the consistency of water.

At this time, you can cover the sills and fenders with masking tape so as not to stain the paintwork. If you plan to make sound insulation, then it is glued to the anticorrosive layer, then the composition is applied directly over it.

Liquid anticorrosive agent can be sprayed with a gravitex gun or applied with a brush. It is necessary to cover the arches and the bottom in 3 layers, and there is no need to make a technological pause until they harden. When applying, it is important to protect the eyes, lungs and exposed parts of the body from getting the composition, as it is difficult to wash off. After treatment, the car can be assembled as soon as the anticorrosive agent hardens and stops sticking to hands and clothes.

The proposed anticorrosive composition is inexpensive and does not have a nauseating odor, like more expensive analogues. The main thing is to carefully prepare the surface for processing so as not to leave gaps with rust or grease-free areas. Small inclusions of it under such anticorrosion are not dangerous, since cannon lard contains corrosion inhibitors. A huge advantage of this composition is its ability to float at the point of impact, that is, if a stone leaves a dent on the protective layer, the mastic will flow into it and seal the damage again.

Watch the video

Similar master classes