Electro OKA on motors from washing machines and car batteries

Electric cars are gaining more and more popularity because they are much cheaper to maintain, but their cost is really high. If you don’t like spending a couple of thousand for gas at the gas station every time, and you don’t have money for a Tesla, then you can convert your old car to electric power.

The first step is to dismantle the internal combustion engine and make an adapter plate to connect the belt drive to the gearbox. Based on the free engine compartment space, it is calculated how many electric motors from washing machines can be placed in it.

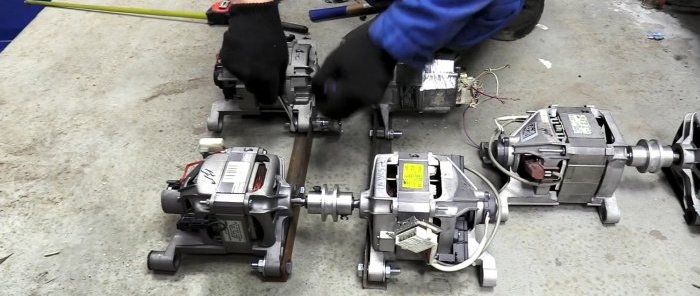

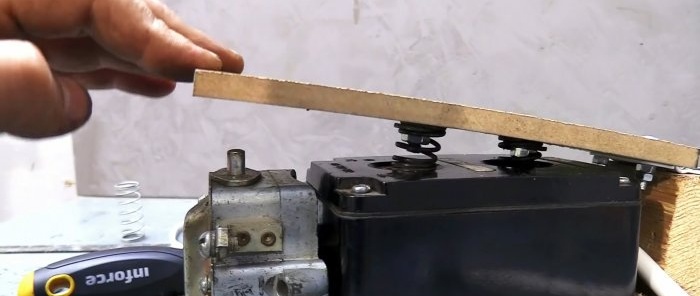

For compact placement, the motors will be connected in pairs. To do this, you will need to machine paired pulleys from an aluminum blank. Then you will need to disassemble the engines, dismantle the anchors and machine their shaft for installing homemade pulleys.

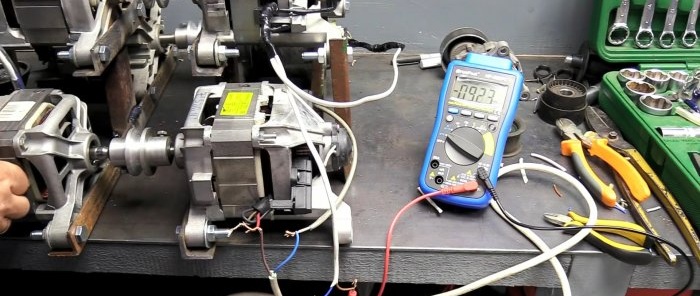

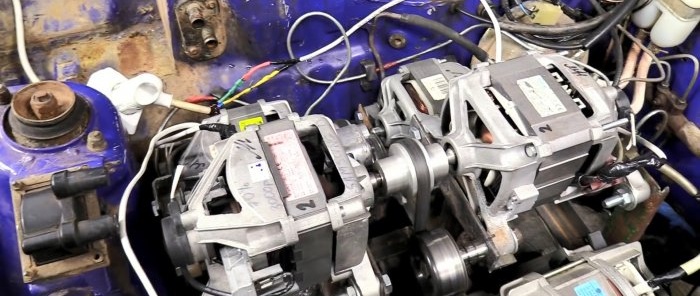

A bracket for installing motors is welded from corners and profile pipes. There is also a roller attached to it to tension the belt. Motors are installed on the bracket. Paired motors must be connected so that they rotate in opposite directions, that is, so that torque is transmitted to the belt in one direction.

A frame is welded under the hood, and the bracket with the motors is fixed to it. Next, the belt is tightened, and the system is checked from the mains.

A stand is installed in the trunk, and conventional lead batteries are placed on it. Ideally, use 20 pieces, but the car will run on 10 batteries. The batteries are connected in series to combine their capacity.

Power from the batteries in the trunk is routed to the engines under the hood via a powerful power button. It can be attached to the gas pedal. In this form the car can already drive.

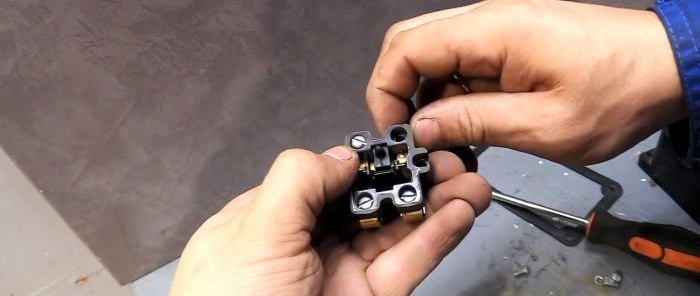

This concept still requires a lot of improvements, but it is quite possible to bring it to fruition. In particular, it is necessary to solve the problem with the electric arc when opening the contacts. Ideally, use contacts from a trolleybus; they do not burn out. The main thing is to achieve a smooth start of the motors so that the car does not jerk. OKA, made according to this principle, with installed 6 motors and 15 old lead batteries, reaches a speed of 40 km/h. The range even with dead batteries is more than 20 km. This is quite enough to drive to work, to the store or to the lake. If you use more motors and new batteries, you will get an excellent car for every day.

What you will need:

- motors from a washing machine – 6-10 pcs.;

- lead batteries – 15-20 pcs.;

- corners and profile pipes;

- wires, terminals, push-button switch;

- aluminum blank for pulleys;

- V-belt.

Refurbishment process

The first step is to dismantle the internal combustion engine and make an adapter plate to connect the belt drive to the gearbox. Based on the free engine compartment space, it is calculated how many electric motors from washing machines can be placed in it.

For compact placement, the motors will be connected in pairs. To do this, you will need to machine paired pulleys from an aluminum blank. Then you will need to disassemble the engines, dismantle the anchors and machine their shaft for installing homemade pulleys.

A bracket for installing motors is welded from corners and profile pipes. There is also a roller attached to it to tension the belt. Motors are installed on the bracket. Paired motors must be connected so that they rotate in opposite directions, that is, so that torque is transmitted to the belt in one direction.

A frame is welded under the hood, and the bracket with the motors is fixed to it. Next, the belt is tightened, and the system is checked from the mains.

A stand is installed in the trunk, and conventional lead batteries are placed on it. Ideally, use 20 pieces, but the car will run on 10 batteries. The batteries are connected in series to combine their capacity.

Power from the batteries in the trunk is routed to the engines under the hood via a powerful power button. It can be attached to the gas pedal. In this form the car can already drive.

This concept still requires a lot of improvements, but it is quite possible to bring it to fruition. In particular, it is necessary to solve the problem with the electric arc when opening the contacts. Ideally, use contacts from a trolleybus; they do not burn out. The main thing is to achieve a smooth start of the motors so that the car does not jerk. OKA, made according to this principle, with installed 6 motors and 15 old lead batteries, reaches a speed of 40 km/h. The range even with dead batteries is more than 20 km. This is quite enough to drive to work, to the store or to the lake. If you use more motors and new batteries, you will get an excellent car for every day.

Watch the video

Similar master classes

How to connect the motor from a washing machine to 220 V

Air compressor from ZIL unit and engine

How to convert a motorcycle into an electric bike that develops speed

How to make a lawn mower from a washing machine

How to convert a gasoline car into an electric car with

How to extend the life of your washing machine

Particularly interesting

Comments (5)