Sandblasting installation from a car candle and a small gas cylinder

There is no more convenient and effective equipment for cleaning metal surfaces from paint and rust than a sandblasting machine. If you have a powerful compressor, you can do it yourself, investing mere pennies in comparison with the cost of the purchased option.

Gas is released from the cylinder. Then you need to open its valve, drill a hole on the side of it and in the bottom.

Weld an internal thread into the side hole, and an external thread into the bottom.Legs made of a profile pipe are welded to the cylinder.

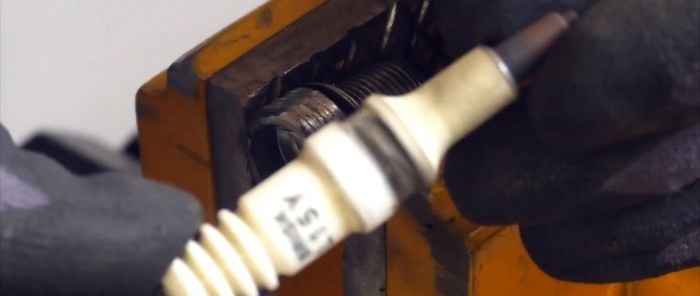

Next you need to remove the ceramic tube from the glow plug. It is inserted into the nut of the collapsible fitting instead, then screwed with an O-ring onto the adapter 1/2 inches to 3/8 inches with external thread.

Next, screw on a similar adapter, but with an internal thread, a 1/2-inch barrel, a ball valve and a 1/2-inch external fitting. The result is a reliable, durable nozzle for spraying sand.

A crosspiece is screwed onto the standard outlet of the cylinder through an adapter. Hose fittings are installed on the sides, one of them is quick-detachable. A pressure gauge is screwed into the top.

A ball valve with a tee is screwed onto the lower thread. Fittings are installed on the sides of the tee. A plug is screwed into the upper side hole.

The usual fitting of the upper crosspiece is connected by a hose to the lower outlet of the tee through a filter. A long hose with a glow plug nozzle is attached to the remaining fitting of the tee. A compressor is supplied to the quick release of the crosspiece.

The plug is used to fill in sifted dry sand.

A cylinder filled with sand is connected to a compressor, and a pressure of 6 atm is injected into it. All taps must be closed. The valve on the cylinder opens first, then in front of the nozzle.

Basic materials:

- small gas cylinder;

- welded internal thread 1/2 inch with plug;

- welded external thread 1/2 inch;

- profile pipe;

- glow plug;

- dismountable threaded fitting 1/2 inch;

- adapters 3/8" to 1/2" with external and internal threads;

- 1/2" barrel;

- ball valves 1/2 inch – 2 pcs.;

- external 1/2-inch fittings for the hose – 4 pcs.;

- fitting for quick-release coupling;

- cross 1/2 inch;

- 1/2" tee;

- pressure gauge;

- hose;

- air filter.

Sandblasting machine manufacturing process

Gas is released from the cylinder. Then you need to open its valve, drill a hole on the side of it and in the bottom.

Weld an internal thread into the side hole, and an external thread into the bottom.Legs made of a profile pipe are welded to the cylinder.

Next you need to remove the ceramic tube from the glow plug. It is inserted into the nut of the collapsible fitting instead, then screwed with an O-ring onto the adapter 1/2 inches to 3/8 inches with external thread.

Next, screw on a similar adapter, but with an internal thread, a 1/2-inch barrel, a ball valve and a 1/2-inch external fitting. The result is a reliable, durable nozzle for spraying sand.

A crosspiece is screwed onto the standard outlet of the cylinder through an adapter. Hose fittings are installed on the sides, one of them is quick-detachable. A pressure gauge is screwed into the top.

A ball valve with a tee is screwed onto the lower thread. Fittings are installed on the sides of the tee. A plug is screwed into the upper side hole.

The usual fitting of the upper crosspiece is connected by a hose to the lower outlet of the tee through a filter. A long hose with a glow plug nozzle is attached to the remaining fitting of the tee. A compressor is supplied to the quick release of the crosspiece.

The plug is used to fill in sifted dry sand.

A cylinder filled with sand is connected to a compressor, and a pressure of 6 atm is injected into it. All taps must be closed. The valve on the cylinder opens first, then in front of the nozzle.

Watch the video

Similar master classes

Particularly interesting

Comments (0)