How to make a powerful vice from a jack - press

When working in a workshop, you often need to squeeze something so tightly that a regular vice is not enough for it. In this case, you should think about assembling a press vice. If you have an extra hydraulic jack, then it will generally be inexpensive, since the metal for homemade work can be purchased at a metal receiving station.

Materials:

- channel 120 mm;

- sheet steel 10 mm;

- corner 30x30 mm;

- pipes 22 and 28 mm;

- hydraulic jack 2t;

- bolts.

Press vice manufacturing process

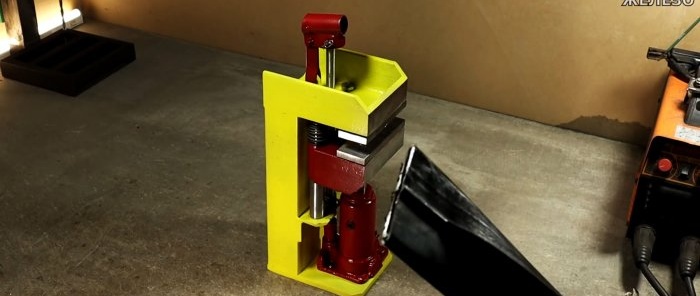

To assemble the frame of the press vice, you need to prepare 3 sections of 120 mm channel, 75, 260 and 155 mm long.

For the jaws, two pieces of 10 mm sheet steel measuring 40x120 mm are prepared.

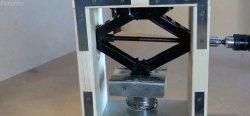

We also prepare 2 guides from a 22 mm pipe, each 155 mm long. Their ends must be welded with inserts with holes and cut M10 threads. From a 28 mm pipe, 2 bushings of 53 mm length are cut.

Additionally, a plate of 10 mm sheet steel measuring 155x120 mm is cut out for the frame. You also need to prepare a piece of corner 30x30 mm with a length of 120 mm.

A more difficult task lies ahead. The frame needs to be welded.To do this, a channel and a 155 mm plate are welded to the 260 mm channel from the sides at right angles. At the same time, holes are drilled on the plate for screwing the jack sole. On a short channel, holes are needed for guide tubes at the bottom, and at the top for fastening the vise jaws.

The tubes are screwed to it, on the other side you need to attach a corner to them, in the center of which you will need to make a large hole for the jack lever. The corner itself is welded.

The sliding part of the vice is made from the remaining short channel. To do this, it is trimmed at the bottom so that it fits tightly onto the bushings. There are 2 holes made in it for screwing the sponge. The part is welded to the bushings.

Next, you need to install the jack and move its bleeding lever to the side of the frame. To do this, it is extended with a rod, which is attached to the standard rod with an extended nut.

Before installing the jack, inserts from sheet steel are prepared for the ends of the vertical channels and welded into them. Also, springs are placed on the guide tubes in front of the bushings to open the vice. They can be wound from springs of a different diameter with a hot torch.

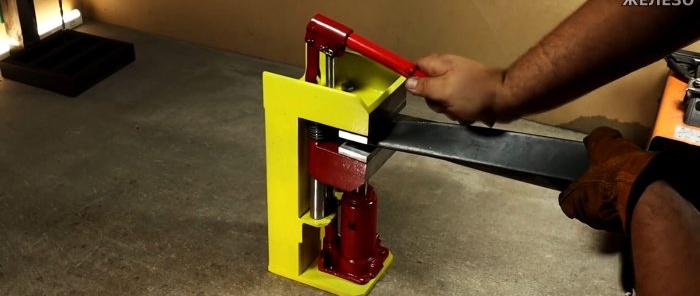

The parts are painted and assembled. The resulting press vice, even on such a compact 2-ton jack, is capable of a lot, even flattening profile pipes

Watch the video

Similar master classes

Particularly interesting

Comments (0)