Bending die for a homemade jack press

To bend metal workpieces evenly and accurately, a bending press is required. This is expensive equipment, the purchase of which is advisable only for professional activities. To solve amateur problems, you can make a press yourself. However, in addition to it, you need to prepare a special stamp.

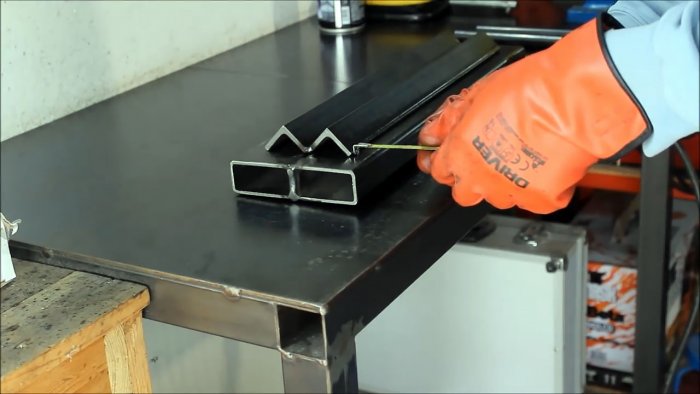

To make the base of the stamp, you need to weld together 2 profile pipes. They are placed in one plane and cooked well. The formed seams are sanded.

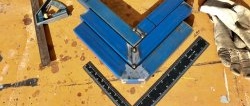

To obtain a 90 degree bending die matrix, you need to weld 2 corners along. The seam should be made at the ends and the formed outer corner so that it does not interfere with the workpieces’ bending correctly. Next, the die matrices are welded onto the profile support platform. It is important that the length of the corners be shorter by a few centimeters on each side of the edges of the platform made of the profile pipe.

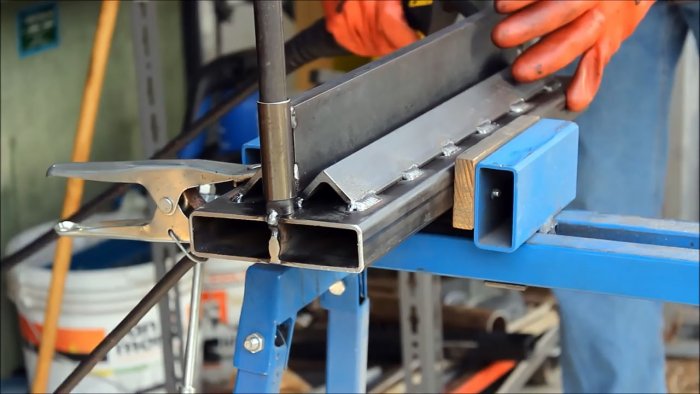

A powerful strip is used to make a punch that presses the workpiece into the die.Its working edge needs to be sharpened. The sharpening should not have a sharp cutting edge capable of cutting into the metal.

Tubes are welded to the ends of the punch. Next, guide tubes of a smaller diameter are inserted into them, which are welded standing to the lower support platform of the press.

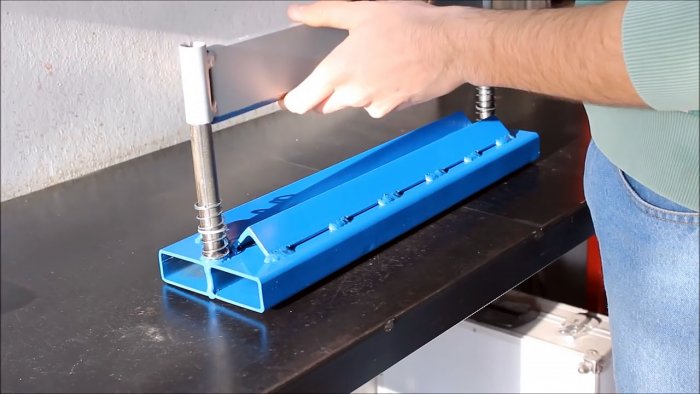

After welding, the punch is removed and springs are placed on the guide tubes. They will allow you not to separate parts of the stamp each time in order to insert blanks between them.

We paint with spray paint.

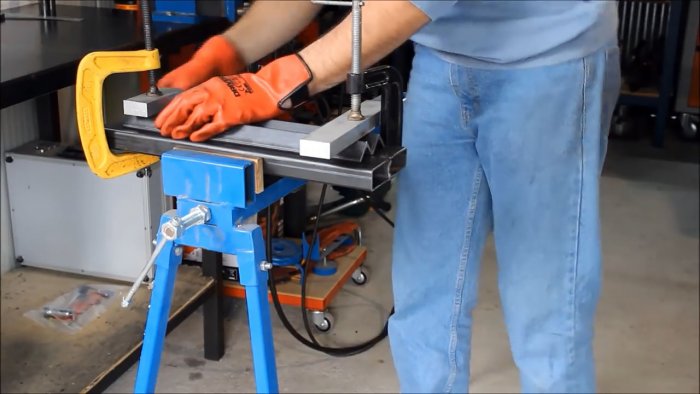

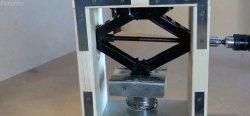

To load the die, you need to weld the press frame from a strong profile pipe. The frame has a sliding crossbar with side tendrils that prevent it from moving. A car jack is used to press it out. At the bottom it is attached to

crossbar, and the top rests against a frame reinforced with a piece of slab. A rod extends down from the moving crossbar. In order for the crossbar to rise when the pressure in the jack is released, it must be suspended on 2 springs.

Having placed the stamp on the press and holding the workpiece between the die and the punch, you need to press out the jack. He will press on the stamp and bend the workpiece. Such a stamp, if equipped with a strong frame with a good jack, is quite capable of bending steel plates 6 mm thick without preheating them.

Materials for making a stamp:

- profile pipe;

- corner 30x30x4 mm;

- strip 10x60 mm or thicker.

- tubes;

- 2 pressure springs

Making a bending die

To make the base of the stamp, you need to weld together 2 profile pipes. They are placed in one plane and cooked well. The formed seams are sanded.

To obtain a 90 degree bending die matrix, you need to weld 2 corners along. The seam should be made at the ends and the formed outer corner so that it does not interfere with the workpieces’ bending correctly. Next, the die matrices are welded onto the profile support platform. It is important that the length of the corners be shorter by a few centimeters on each side of the edges of the platform made of the profile pipe.

A powerful strip is used to make a punch that presses the workpiece into the die.Its working edge needs to be sharpened. The sharpening should not have a sharp cutting edge capable of cutting into the metal.

Tubes are welded to the ends of the punch. Next, guide tubes of a smaller diameter are inserted into them, which are welded standing to the lower support platform of the press.

After welding, the punch is removed and springs are placed on the guide tubes. They will allow you not to separate parts of the stamp each time in order to insert blanks between them.

We paint with spray paint.

To load the die, you need to weld the press frame from a strong profile pipe. The frame has a sliding crossbar with side tendrils that prevent it from moving. A car jack is used to press it out. At the bottom it is attached to

crossbar, and the top rests against a frame reinforced with a piece of slab. A rod extends down from the moving crossbar. In order for the crossbar to rise when the pressure in the jack is released, it must be suspended on 2 springs.

Having placed the stamp on the press and holding the workpiece between the die and the punch, you need to press out the jack. He will press on the stamp and bend the workpiece. Such a stamp, if equipped with a strong frame with a good jack, is quite capable of bending steel plates 6 mm thick without preheating them.

Watch the video

Similar master classes

Particularly interesting

Comments (0)