How to make a pump from an old car strut

The front shock absorber strut remaining after the suspension repair can be converted into a hand pump for inflating tires. This is a simple, indestructible tool, yet quite compact to carry with you in a backpack. The main thing is that its production will cost almost nothing, since almost all the parts are already in the shock absorber.

It is necessary to disassemble the shock absorber and drain the oil from it. It will require an inner sleeve and a rod.

You need to disassemble the sleeve by hitting the rod. The latter needs to be clamped in a vice and a plate cut out of it. Only the piston and its adjacent parts should remain on the rod.

The sleeve is disassembled into a tube. Next, you need to remove the pin from the ball joint and clean it until it shines.

The threaded part is cut off from the pin, and the rod is also shortened in order to weld them together in the future so that they do not stick out too much from the sleeve.

The bushing and nut are returned to the rod. It is then welded to the finger as evenly as possible. The weld seam is cleaned.

Next you need to plug the sleeve.To do this, the M6 nut is pressed into the washer, and they are welded together. The resulting part is welded into the sleeve tube.

A hole is drilled in the side of the sleeve closer to the open edge. It is lubricated from the inside and a rod is inserted into it. Then a hose is screwed to the pump, and it can be used for its intended purpose for inflating tires and balls.

Materials:

- front pillar;

- bicycle pump hose;

- M6 nut

- washer M12.

Pump manufacturing process

It is necessary to disassemble the shock absorber and drain the oil from it. It will require an inner sleeve and a rod.

You need to disassemble the sleeve by hitting the rod. The latter needs to be clamped in a vice and a plate cut out of it. Only the piston and its adjacent parts should remain on the rod.

The sleeve is disassembled into a tube. Next, you need to remove the pin from the ball joint and clean it until it shines.

The threaded part is cut off from the pin, and the rod is also shortened in order to weld them together in the future so that they do not stick out too much from the sleeve.

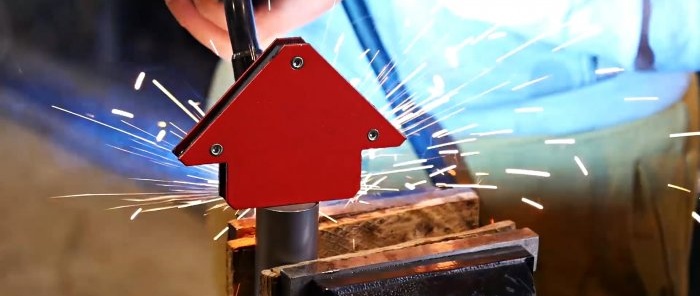

The bushing and nut are returned to the rod. It is then welded to the finger as evenly as possible. The weld seam is cleaned.

Next you need to plug the sleeve.To do this, the M6 nut is pressed into the washer, and they are welded together. The resulting part is welded into the sleeve tube.

A hole is drilled in the side of the sleeve closer to the open edge. It is lubricated from the inside and a rod is inserted into it. Then a hose is screwed to the pump, and it can be used for its intended purpose for inflating tires and balls.

Watch the video

Similar master classes

How to convert a refrigerator compressor into a vacuum pump

How to make a free concrete vibrator from a car

How to increase the pressure and performance of a Brook type pump

How to make a vacuum pump from a refrigerator compressor, and where

How to make a car lift in your garage

How to make a cherry pitter from a syringe

Particularly interesting

Comments (0)