Galvanizing steel at home

The most durable zinc coating on steel can be applied by electroplating at home. If the part is small, then it is not even necessary to have a powerful power supply, just batteries are enough. Let's look at the process of galvanizing steel from A to Z.

What you will need:

- water;

- soda ash;

- vinegar;

- zinc plate or rod;

- wires;

- AA battery.

Do-it-yourself galvanizing process

A steel product that needs to be protected with a layer of zinc must first be cleaned of rust. This is done with a vibration machine with sand, sandblasting, sandpaper or in a solution of citric acid.

The part must be clean and smooth, otherwise the coating will lie unevenly.

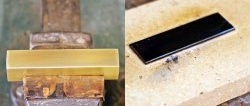

The essence of the process is that the product will be placed in an electrolyte bath along with a zinc electrode. They will be connected to the battery, as a result of which zinc particles from the electrode will be transferred to this object. To do this, you only need to connect “–” to the product and “+” to the electrode.

To work, you need to prepare an electrolyte. Soda ash is added to ordinary warm tap water to adjust the pH, at the rate of 1 spoon per 0.5 liter.

Then add a little vinegar to acidify the solution.

After this, you need to connect the zinc anode with a wire to the positive contact of the AA battery, and the product itself for galvanizing to the negative.

To begin the galvanic transfer of zinc to the object, they are dipped into an electrolyte after degreasing.

The duration of the process depends on the power of the DC source and the size of the product. You need to periodically remove it and monitor the process.