A way to coat steel with zinc without electrolysis at home

To reliably protect a steel product from corrosion, it can be coated with zinc. Its layer is much more durable than paint, and it is also abrasion resistant. Zinc coating can be applied at home using a very simple technology.

Materials:

- zinc scrap (old carburetor);

- battery electrolyte;

- soda ash;

- solvent.

Zinc Plating Process

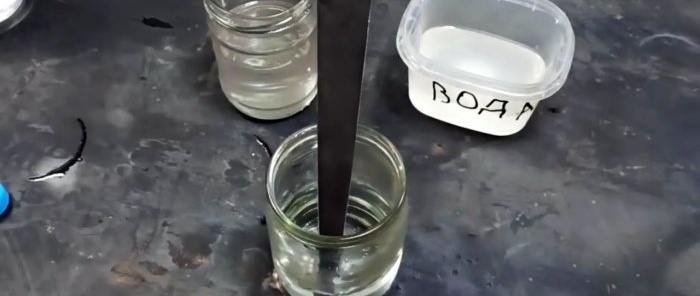

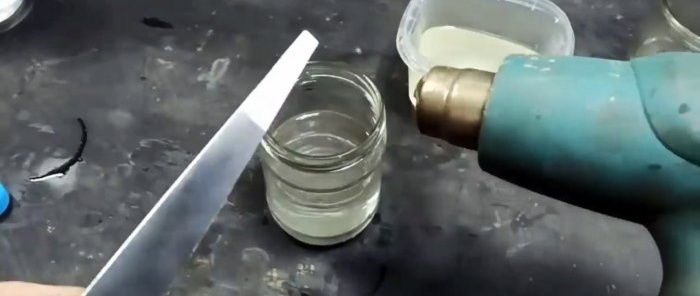

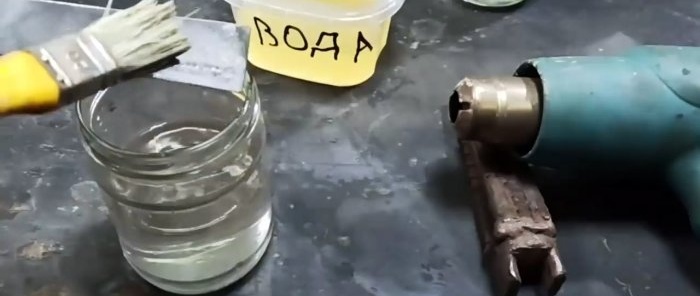

It is necessary to prepare scrap zinc, for example, a body from an old carburetor, or buy granulated zinc at a chemical store. Pieces of carburetor or granules are poured into a jar with a small amount of electrolyte for the battery. After about a day, the zinc will dissolve, which will be indicated by the cessation of bubbling. The resulting cloudy solution must be filtered through a funnel with cotton wool. Next, prepare a bath with water and soda. You will also need another glass jar, which should be filled with clean electrolyte. The part to be coated with zinc is ground and wiped with a solvent.Then it must be immersed in clean electrolyte for 10-20 seconds. After this, it is dipped in a soda solution and wiped dry. Now the part in the treated area needs to be heated to 400-500°C. This is done with a hair dryer or a torch. The degree of heating can be determined by the color of the tarnish. You need to heat the metal until it turns gray. Once it begins to turn reddish brown, you need to immerse the part in a zinc solution. After this, the remaining acid is washed off with water and soda. The process can be repeated several times to make a couple of layers of zinc. Only in this case it is difficult to determine the temperature without a pyrometer, since the tarnish color is not visible through the coating. If the part is too large to be dipped, the zinc coating can be applied with a brush.Watch the video

Nickel plating at home - https://home.washerhouse.com/en/7223-nikelirovanie-v-domashnih-uslovijah.htmlSimilar master classes

Particularly interesting

Comments (0)