How to repair a plastic mount

When dismantling a headlight for maintenance, one of its fasteners often breaks off. This is unpleasant, but not a disaster, since everything can be fixed. Anyone can do this; it only requires a soldering iron and 20 minutes of free time.

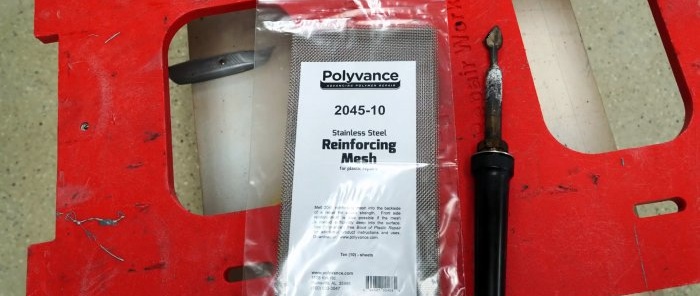

Materials:

- Stainless steel mesh for soldering plastic;

- soldering rods.

Headlight mount repair process

First of all, you need to cut 2 narrow strips from the soldering mesh, which are folded at right angles.

Then they are fused into the broken fastener with a hot soldering iron with a wide tip. The latter can be turned or spattered from a rod.

At the next stage, the paws created by the mesh need to be fused into the main plastic part. Before this, the contact surface is slightly sanded with sandpaper.

To strengthen the soldering, a rod made of the same plastic that is being repaired is fused on top.

After the plastic cools, this mount will hold even stronger than initially. This repair method is much more reliable than using any glue, and it is also very cheap.