We do the simplest sandblasting in 20 minutes

Nothing removes corrosion or old paint as quickly and efficiently as a stream of sand and air. If you have a compressor, then you simply must sandblast it. We offer the fastest and easiest way to make it.

Materials:

- Blow gun;

- cold welding;

- plastic bottle;

- small screws – 2 pcs.

The process of making a simple sandblast

It is necessary to machine the wall of the blow gun tube from above, closer to its body. The width of the resulting hole should be approximately 6-8 mm.

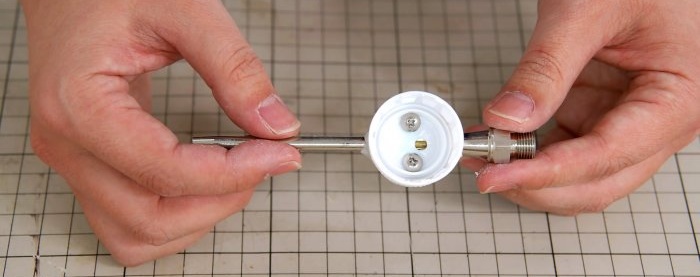

Next, you need to drill the cap of the PET bottle with a 3 mm drill. The hole is made slightly off center. 2 holes are made along the edges of the lid with a 1 mm drill.

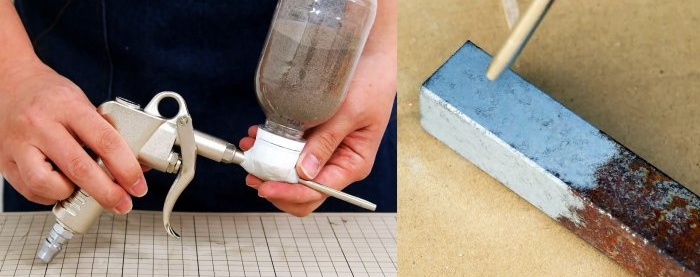

2 self-tapping screws are inserted into the side holes in the cover from the inside. Next, you need to clean the blow gun tube near the machined hole until rough.

After this, a cover with self-tapping screws for cold welding is glued onto it. The hole in it and the tube must be aligned. Thanks to the screws, the lid will hold securely.

Now dry sifted sand is filled into a small PET bottle and it is wrapped in a cap on the gun.

The equipped sandblaster is connected to a compressor with a receiver. When air is supplied, sand from the tube will be supplied with high acceleration to the workpiece. Be sure to place cardboard or fabric under the parts when working with it. This will allow the sand to be collected back. It can be sifted and reused many times.

Watch the video

Similar master classes