How to make a latch on a door with a secret lock

Owners of garages and workshops worry about the safety of their tools and other valuables stored there. Such buildings always attract intruders. We propose the design of a very simple homemade lock, which cannot be opened with ordinary master keys available in the arsenal of thieves.

Materials:

- Sheet steel 4-6 mm;

- strip 30 mm;

- blank for turning;

- M10 bolt.

Lock making process

The base of the lock is made of a thick sheet steel plate measuring 150x80 mm. It is drilled in the corners for attachment to the inside of the door.

Then it must be drilled with a 15-20 mm drill along a visually drawn longitudinal line through the center, with a slight offset from the middle to one edge.

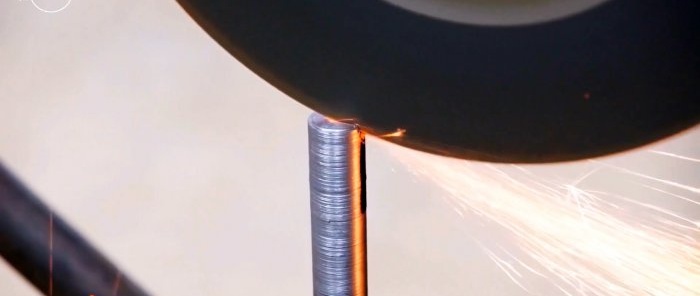

On a lathe you turn out a massive washer and a hollow bushing with a cap on the edge. You need to insert the bushing through the washer into the hole on the plate and weld it on the back side.

A bolt from the strip is welded onto the washer in front of the lock. It should extend beyond the plate by 70-100 mm.Its edge is cut at an angle, and a 12 mm wide cut is also made on it to enter the rod of the lock mate.

A valve travel limiter is welded onto the plate so that it blocks its lifting, preventing it from being thrown over. You can use a piece of square rod as this.

The mating part of the lock measuring approximately 80x60 mm is cut out of sheet steel. It must be attached to its body with a gap of 10 mm, and the location of the groove on the valve must be marked. Then it is drilled along this mark. An M10 bolt is welded into the hole. The corners of the plate are drilled and countersunk.

Now we need to work on the key. It is turned from a rod. From one edge its diameter is ground off so that it can fit into the welded sleeve. On this side it should be sawed lengthwise.

The workpiece is drilled from the edge of the cut. An L-shaped hook cut from thin sheet steel is riveted into the resulting hole. The thickness of the hook should be less than the cut in the key so that it can easily fold inward without friction.

The key should fit easily into the sleeve so that the hook on the back falls out. Now you need to look at its position on the washer in order to weld a rod hook into this place. This way, the hook will be able to rest against it, and thereby lift the valve.

The key is drilled from the back side, and a rod is inserted into it, the edges of which are riveted. It turns out to be a comfortable handle.

The lock is screwed onto the door from the inside, and a counter part is installed opposite it on the frame or wall. The door leaf will need to be drilled opposite the bushing for the key to enter.

The result is a simple but powerful massive lock. Conventional thin picks bend when gripping the valve, since it is very heavy for them.Its combination with commercial locks will significantly increase the security of your workshop or garage.