6 ways to repair blind holes in wooden parts with your own hands

Repair wooden furniture Professional carpenters are very good at it; they can restore wooden parts so that they seem new. But what to do if you are not a professional, but you don’t want to pay a good carpenter? Today you will learn how to seal blind holes in any wooden parts with improvised materials.

As an example, we will take 6 standard pieces of wood, each with three blind holes, and seal them in six different ways, three of which will have different types of plugs.

To begin with, we will need simple tools - a pair of hacksaws (you can get by with one), a rasp, a Kreg Jig device for joining with self-tapping screws, in our case it will serve for making blind holes and connecting two wooden parts of the workpiece to each other, a grinder, a clamp, in our case also a small band saw.

From the materials we prepared, we prepared wood putty, wood glue, sawdust, car putty, special plugs for oblique holes, and a long 10 mm round strip for making homemade plugs.

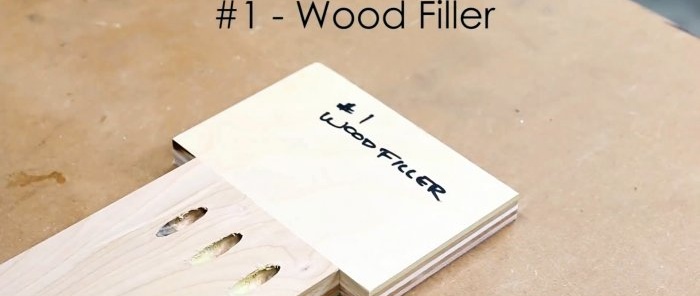

Method No. 1 - wood putty

In theory, wood putty is precisely intended for filling uneven areas, but it is not recommended to fill deep holes with it; over time, the putty may crack.

We fill the holes with putty, leave it to harden, then sand it - the result is pleasing, it’s perfect! If you then paint the workpiece, the putty will not be visible, the only problem is that the putty does not like physical impact and can crack over time.

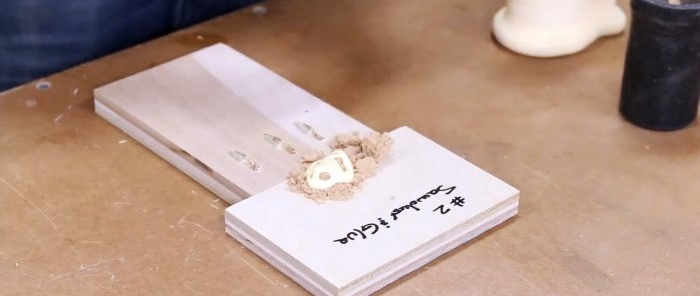

Method number 2 - glue plus sawdust

We do the same as in the case of wood putty, only we fill the holes with glue mixed with sawdust.

We left it to dry for 24 – the glue didn’t harden much, and the sanding didn’t work out very well. But if you used epoxy instead of glue, then everything would go much better.

Method No. 3 - automotive putty

Everything is the same as in the case of wood putty, only car putty needs a hardener. It dries quickly, depending on the amount of hardener, no more than 2 hours, it is polished to a “mirror” - the result is pleasing.

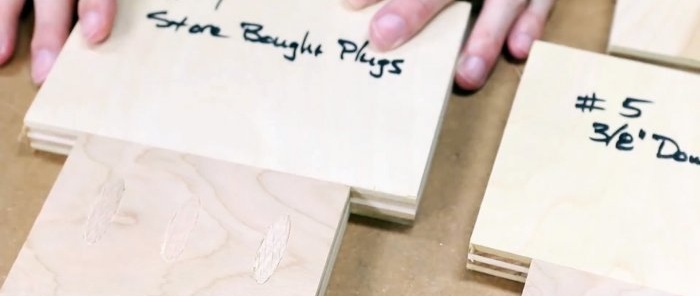

Method No. 4 - store plugs

Special magazine plugs are pushed into holes lubricated with glue. After half an hour the glue will dry, cut off the protruding ends of the plugs with a hacksaw and grind them.

The main disadvantage of this option is that such plugs are quite difficult to buy, and they are quite expensive.

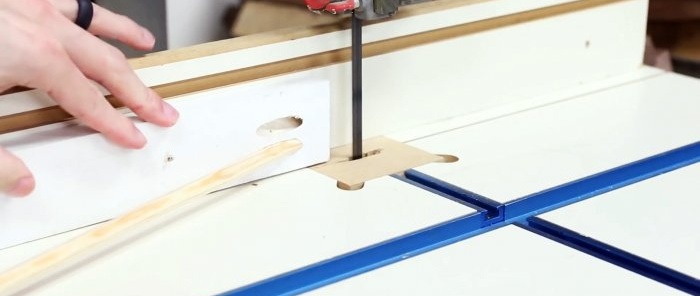

Method No. 5 - since it’s expensive, we’ll make an analogue to store plugs ourselves

We take a block, make an oblique blind hole in it, insert a round strip into it and cut it with a band saw.As a result, we get a homemade cheap analogue of purchased plugs!Next, everything is similar to store plugs. But the result after sanding is not so ideal; small holes remain.

Method No. 6 - homemade simple plugs

This method couldn’t be simpler - we cut 3.8 cm pieces of slats using any method, hammer them into holes lubricated with glue, cut them, and sand them. It turns out better than option No. 5.

Now you know how and with what you can seal blind holes in wood.

Watch the video

Similar master classes