How to convert an asynchronous electric motor into a powerful electric generator

Many people think about obtaining free electricity by converting the kinetic energy of wind or water into it. Wind generators or mini hydroelectric power plants of sufficient power sold for this are very expensive. To save money, a generator for your installation for producing free energy can be made based on a conventional electric motor.

What you will need:

Generator manufacturing process

To make a generator, you need to disassemble an asynchronous three-phase motor. The rotor is removed in order to equip it with permanent magnets in the future.

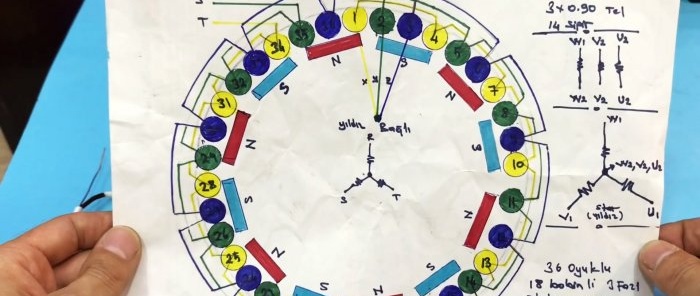

Next you need to decide on the number and size of magnets. They should be in the form of rectangles. Moreover, in width, each magnet must completely cover 2 grooves on the stator core, that is, lie on 3 spikes. In this case, it will act with its field on 3 stator winding coils at once. For the motor in this example, a magnet with a width of 25 mm is suitable.

The core of this stator consists of 12 groups, which include 3 spikes.Thus, 12 rows of magnets need to be attached to the rotor. Polarity alternates between them. The magnets of each row should be lined up corresponding to the length of the rotor core. Since 40x25x10 mm magnets were chosen for the manufacture of the generator, they are placed 3 in a row.

You need to secure the magnets to the anchor using epoxy glue. Since this will increase the diameter of the rotor, it may need to be machined before this so that after adding magnets it can fit into the stator.

Such a number of neodymium magnets on the rotor makes it problematic to install it in the stator, since they are attracted. There is a risk of injury during installation, so do not place your fingers between the attracting cores.

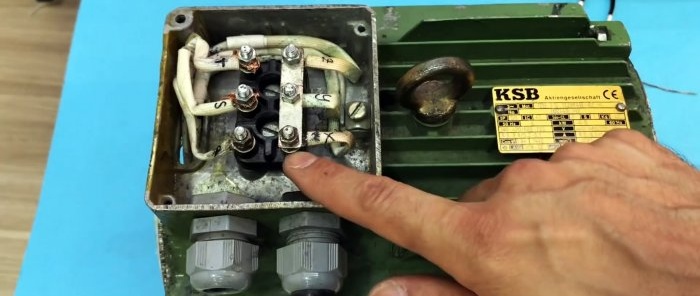

The engine is being assembled. After this, you need to modify its terminal block. It has 6 winding terminals that need to be connected in a star circuit. It is necessary to connect 3 of them into one node. Then between it and any other remaining end of the winding there will be 220V.

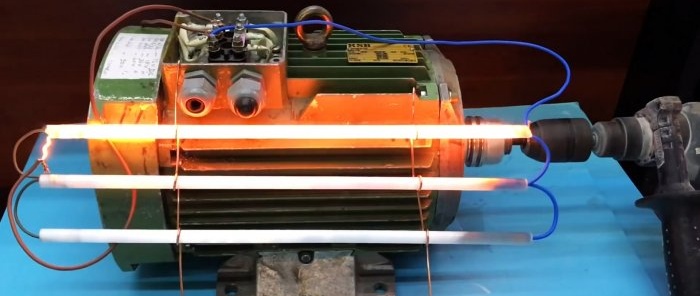

After this, the generator can be connected using a gearbox to a windmill or made into a mini hydroelectric power station. It is also possible to connect it directly to an internal combustion engine. With sufficient speed, it can power almost any household electrical appliance.

Watch the video

Similar master classes