How to make a bathroom sink from ceramic tiles

When renovating your bathroom, you can abandon the classic store-bought sinks and make your own washbasin from large-format tiles. This is a very beautiful exclusive solution that has nothing in common with the usual plasterboard countertops covered with mosaics. This sink just looks 100 times better.

Materials:

- Large format tiles;

- ready-made acrylic tile adhesive;

- scotch.

All kinds of tools for cutting tiles from Aliexpress at a discount - http://alii.pub/61d7zn

Sink making process

In a whole large-format tile corresponding to the size of the desired countertop, you need to cut a rectangular hole in the center for the sink.

The tile is turned over, and a bevel is made on the cut edges at 45 degrees. It is important to avoid chipping the face glaze. This type of milling is most conveniently performed with a “turtle” type disc.

Now the tiles are installed face up, edges on 2 tables or trestles. You need to glue 3 side walls of the sink onto it. They are cut from tiles. There is also a groove on the sides. Then we glue strips of tape and apply glue to the hook.

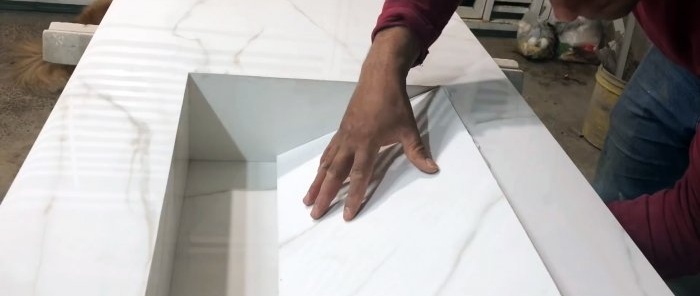

You need to glue the tiles on the sides and on the far wall. The parts are aligned at right angles and secured together with tape until the glue hardens.

After the glue sets, the tabletop is turned over and the bottom is glued to 3 walls. It doesn't need a hook. You just need to sand down the glaze a little around the edges to improve adhesion.

We wait for it to dry and turn the countertop and sink over again. Now you need to make the front oblique wall. A groove is made on the prepared tile along the longitudinal sides. On one side at an acute angle, and on the other at a standard 45 degrees. The part is glued in and temporarily secured with tape.

The last visible element will be the manufacture of a false bottom to hide the siphon. To do this, a small tile is cut out a little wider than the bottom, and a groove is made on one longitudinal side of it. On the reverse side, several layers of thin scraps are glued onto it.

The assembled sink needs to be strengthened by coating the corners with glue and installing stiffeners from thin scraps.

A hole is drilled in its bottom for the siphon, and at the top for the mixer. If required, you can also glue a narrow strip of tile to the front side of the countertop. It is just convenient to attach stiffening ribs to it.

Such a sink is installed on a frame made of wood, metal profiles, or a support made of brick or gas block. The siphon is closed with a cover. The result is exclusive plumbing fixtures that you definitely can’t buy in a store.

All kinds of tools and devices for cutting ceramic tiles from Aliexpress at a discount - http://alii.pub/61d7zn

Watch the video

Similar master classes

Particularly interesting