How to grease a sealed bearing without disassembly

The problem is that closed-type bearings are practically sealed, it is difficult to place thick lubricant behind the sealing rings, and the effect of specialized liquid lubricant does not last long. There is a little trick on how to lubricate sealed bearings without disassembling, let's look at the example of roller skates.

Over time, the skates lose momentum and begin to squeak. The proposed method allows you to lubricate the bearings with ordinary cheap thick grease, and get even better results than an expensive, more fluid special one.

What you will need:

- Hex key;

- flat screwdriver;

- grease;

- Vacuum pump;

- thin hose;

- check valve;

- jar with screw cap;

- can.

Roller skate bearing lubrication process

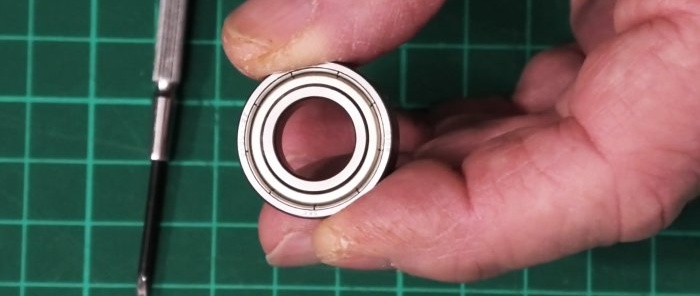

Using a hex wrench, you need to unscrew the wheels of the skates. Then we pry up the bearings with a screwdriver and remove them together with the bushing.

Next, place the bearings in a container with solvent to remove all contaminants from the surface.

If you place the dismantled bearings in a jar of liquid lubricant, it will flow into the cavities and lubricate the balls. But then it will also leak out, so the bearings will crunch again after a while.

To use thick lubricant, you need to preheat it in a tin can on the stove, ideally in a water bath. This will make it thinner.

The bearings are thrown into the liquefied lubricant.

They must drown in it. The tin container is then placed in a glass jar with a vacuum pump connected through a tube and a check valve.

The pump will pump out air so that even thick grease can penetrate into the bearings.

After this, you can wipe it and install it back, forgetting about servicing the rollers for a long time.

Watch the video

Similar master classes