How to make a 12V pocket induction boiler

An induction coil can heat metal objects extremely quickly. If you assemble it according to the proposed scheme, you can get an induction boiler for boiling water in a steel container such as a cup or pan. This is a completely working device that can be used in practical applications.

Materials:

- Printed circuit board;

- resistors 330 Ohm, 10 kOhm – 2 pcs. - http://alii.pub/5h6ouv

- rectifier diodes IN4007 – 2 pcs. - http://alii.pub/5m5na6

- capacitor 1 µF - http://alii.pub/5n14g8

- inductor 50 mH - http://alii.pub/66lx1w

- transistors IRFZ44N – 2 pcs. - http://alii.pub/5ct567

- radiators for transistors – 2 pcs.;

- steel bar;

- copper wire in enamel.

Manufacturing Process of Low Voltage Induction Heater

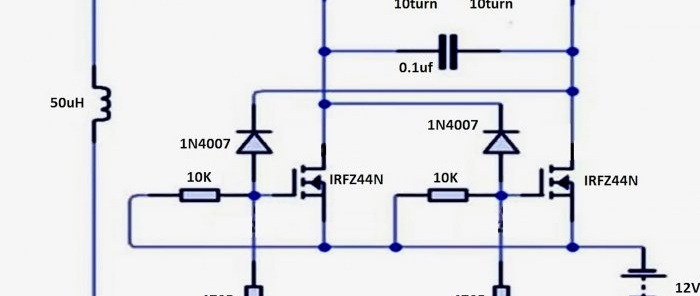

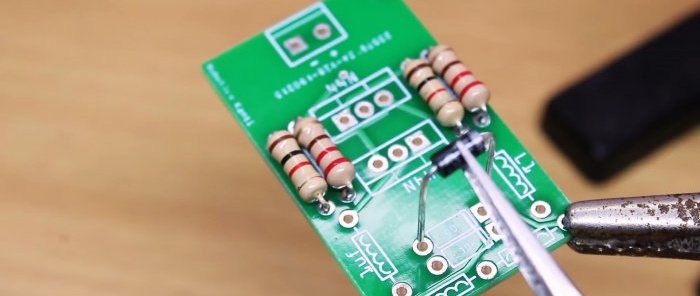

The coil will be assembled according to the presented diagram. To do this, a printed circuit board is first prepared for it. 2 resistors of 10 kOhm and 2 of 330 Ohm are soldered into it.

Next, a pair of IN4007 rectifier diodes are soldered into the board. Behind them a 1µF capacitor and a 50 uH inductor are added.

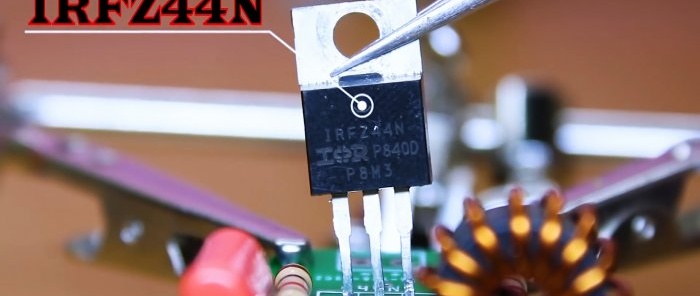

IRFZ44N transistors are soldered to the board according to diagram 2. Aluminum radiators are installed to cool them.

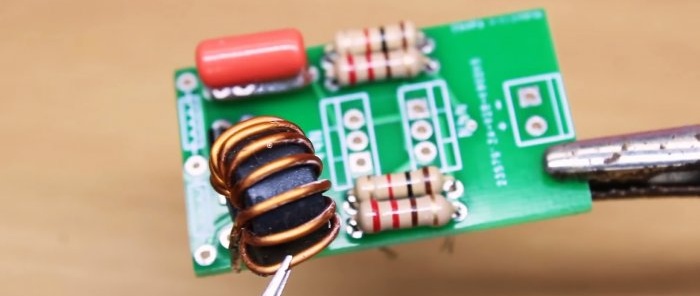

Then you need to cut out a core from a metal bar and wrap it with enameled copper wire. 10 turns will be enough. The coil is connected to the circuit. It is necessary to leave a gap between them so that the board does not heat up from the steel body.

The device is powered from a 12V source. When the device is turned on, it sticks to steel surfaces due to the magnetic field.

The heater can be mounted in this way on a metal mug, and due to induced eddy currents, water can be boiled in it.

Watch the video

Similar master classes