How to make a simple and powerful induction soldering iron with instant heating

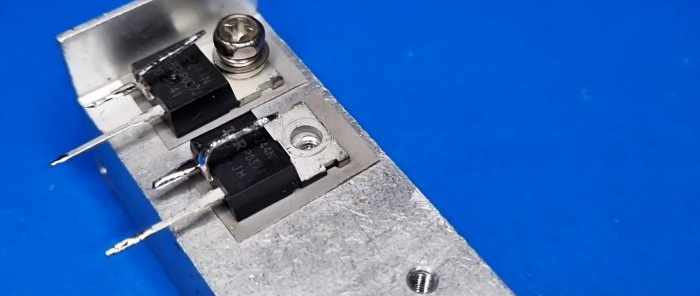

A quickly heated and efficient portable soldering iron from a low-voltage power source is assembled quite simply and quickly using two power N-channel IRFZ44N field-effect transistors. They are ideal for driving high-power loads because their n-channel has low resistance and power dissipation can exceed 100 W. Of course, you need a good heat sink (radiator), from which you need to start assembling the device.

Details

- 2 transistors IRFZ44 - http://alii.pub/5ct567

- ferrite core 15-20 mm - http://alii.pub/66lwtq

- 2 resistors per 1 kOhm - http://alii.pub/5h6ouv

- 2 diodes 1N4007 - http://alii.pub/5m5na6

- inductance (choke) 220 µH - http://alii.pub/66lx1w

- power button - http://alii.pub/5nnu8o

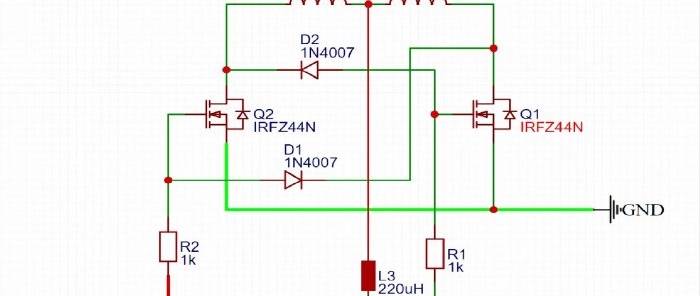

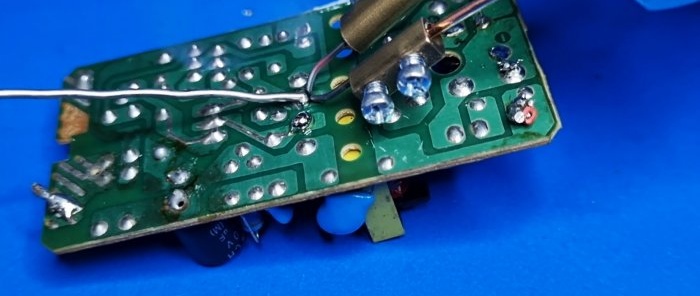

Pulse soldering iron circuit

An extremely simple diagram with a minimum number of parts.

Making a soldering iron with instant heating

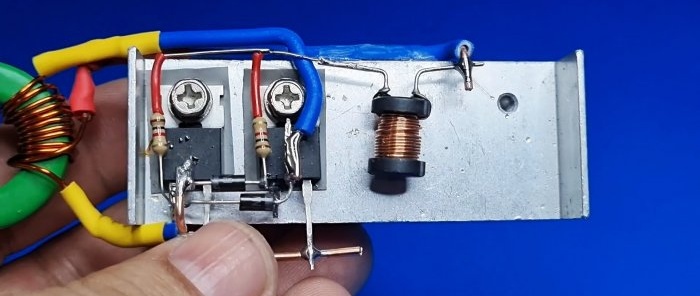

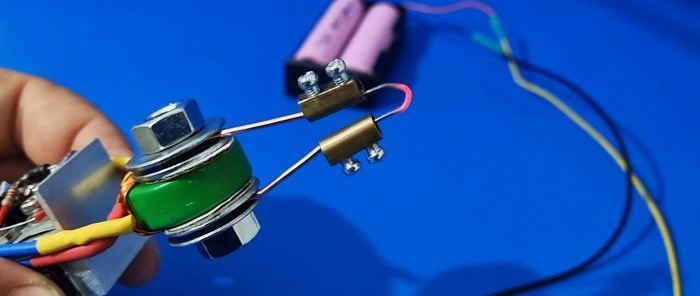

Since the IRFZ44N transistor is produced in a housing with a mounting hole for a screw, an appropriate radiator is selected for further installation.To make soldering easier, the drain leg of the transistors is bent, the gate is shortened slightly, and the field switches are attached to the substrate so as not to come into contact with it.

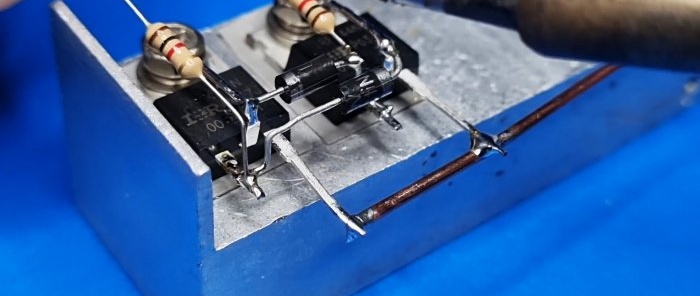

Next, their sources are connected by a common bus, and low-power rectifier diodes are soldered between the drains and gates of the triodes (cathode to drain).

Now take two resistors 1 kOhm 0.25 W. Each of them is connected with one leg to the gate of the transistor, the other legs are soldered to each other. A 220 µH inductor is also soldered there.

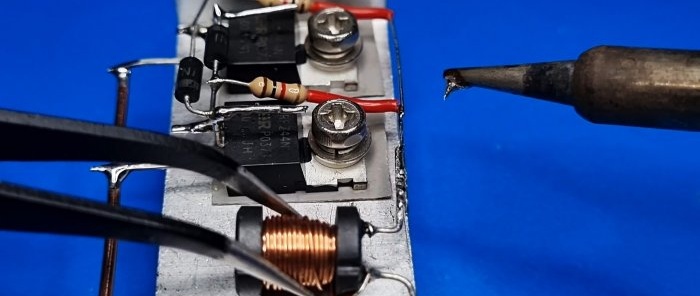

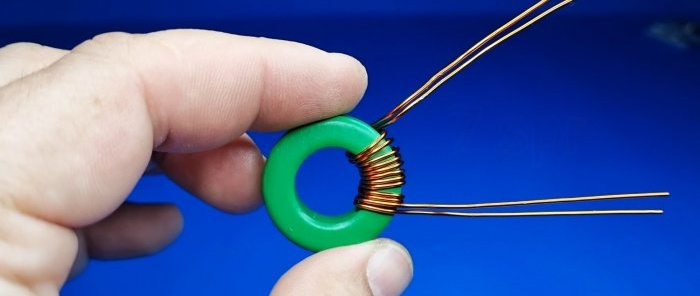

The transformer is wound on a medium-sized (15-20 mm) toroidal ferrite core with 0.8 mm copper wire.

It is folded in half and wound in 7 turns.

Then one winding is shunted.

The central wire of the transformer is soldered to the second leg of the inductor, and the side wires are connected to the drains of the transistors.

A metal core is inserted into the ring, but in such a way that it does not come into contact with the windings.

Contacts for the tip are attached to it on both sides.

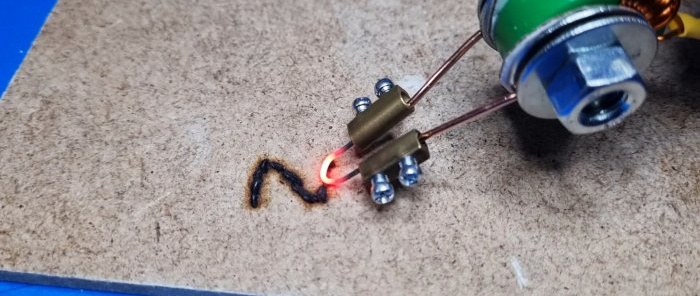

An ordinary paper clip can serve as a sting. You can use copper, but the expected heating of the tip is 170 degrees Celsius, so it is better to use brass.

All that remains is to install the power switch and apply power. Instead of a switch, it is convenient to use a Velcro tact button. It is connected to the power supply gap of two resistors.

The circuit is powered by a constant voltage of 8-12 V, “+” is supplied through L to the central point, “-” - to the sources of the transistors.

This is a good effective soldering tool for desoldering SMD parts, LEDs and performing other indiscriminate rations. You can reduce heating in it by changing the voltage or installing a less powerful coil.

The device is also perfect as a safe device for wood burning, if necessary.

The soldering iron works perfectly with two 18650 series batteries.

Watch the video

Similar master classes