How to make an instant heater from an induction cooker for forging and hardening metal

Induction heating is faster than any furnace. With its help, you can heat a steel part red-hot in a matter of seconds. Having a regular induction cooker, you can assemble a heater that will allow you to heat metal for forging, hardening or tempering.

Basic materials:

- Induction cooker - http://alii.pub/678vcs

- 1/4 and 3/8 inch copper tubing;

- fittings for 3/8 inch pipe with external thread – 2 pcs.;

- nuts for fittings – 2 pcs.;

- mini pump;

- copper welding cable;

- cable lugs – 2 pcs.

Induction heater manufacturing process

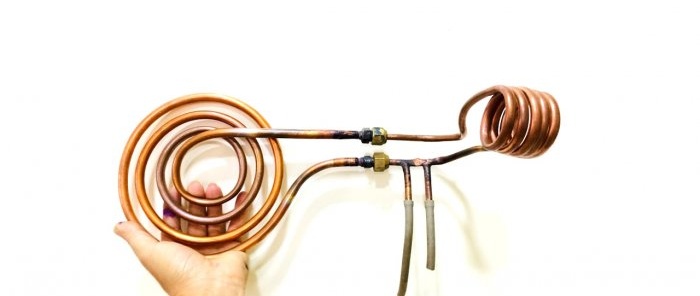

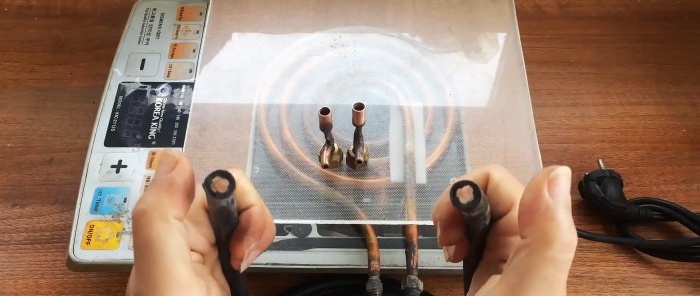

To make a heater, you need to bend a spiral from a 3/8-inch copper pipe, equal in size to the stove coil. Fittings with external threads are installed at its ends. The spiral is then secured above the coil. You can screw plexiglass onto the stove, then a plywood spacer, and again plexiglass, as in the photo. In this case, the spiral will lie between the glasses.

Then you need to make 2 tees from the 1/4 inch pipe.To do this, a small section is flared for installation of the nut. Then the workpiece is drilled in the middle.

Another short piece of pipe is soldered onto the hole.

The end of the workpiece opposite the nut must be compressed to seal. Then a piece of 3/8-inch tubing is put on it and soldered. This will be a sleeve for crimping the cable.

Next, we take 2 thick copper cables, strip their ends, and crimp the cores into the tee sleeves.

The tees are screwed onto the spiral fittings and tightened. Hoses are pulled onto the side outlet, through which water will then circulate for cooling.

Now, when you turn on the stove, the parts clamped between the ends of the wires will heat up and weld together. For example, you can attach copper clips to the cable lugs to secure the jaws of the pliers. Then, by clamping one part in some, and the second in others, you will be able to weld them.

In order not to overheat the copper spiral, a pump is connected to the hoses on the tees, which will pump water.

To use the device for heating steel workpieces, you need to install a handle made of plastic or wood on the ends of the cable.

A coil of the required diameter is rolled into 3-4 turns from thick copper wire or a thin tube. At its ends there are lugs or lugs for connection to the cable on the handle.

Now we start the pump to circulate water in the main spiral, and turn on the stove to maximum. After this, we place the steel blank inside the coil on the handle. It will heat up red hot in a matter of seconds.

You can install a thicker spiral to heat massive workpieces.