How to weld gaps in thin metal without difficulty

When welding thin metal, in order to avoid burn-through, all aspects of the welding process are important: the diameter and type of the main electrode used, the strength of the welding current, the speed and trajectory of the electrode, the quality of stripping of the parts being welded, etc.

But in some cases, when welding thin metal at various gaps, all of the listed factors are not enough and then another factor is applied, related to the use of filler material. Moreover, in all cases, welding is carried out with an intermittent arc and the electrode is moved in the transverse direction. Let's look at how to apply this method one by one.

Welding electrodes for general purposes on AliExpress at a discount - http://alii.pub/606j2h

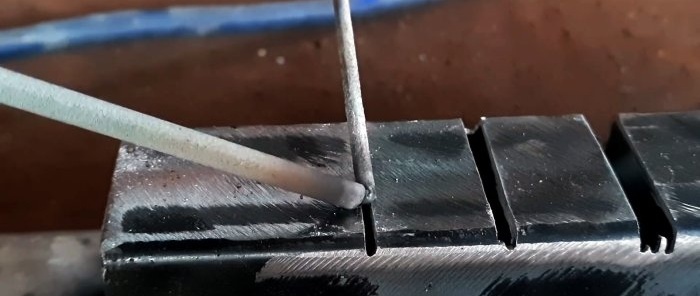

Method 1: gap less than filler material diameter

This is considered to be a gap between the parts being welded, the width of which is less than the diameter of the filler material. The end of the electrode without coating or welding wire is melted by the main electrode by moving it transversely from the edge of one part to another through the filler material.

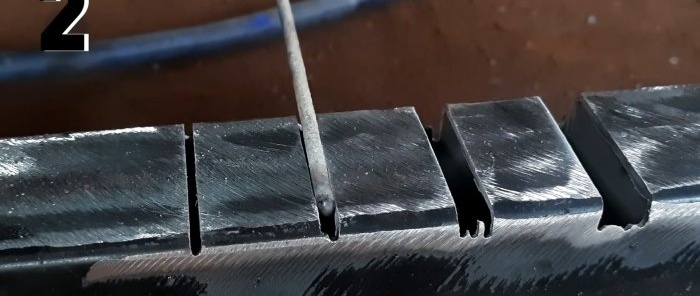

Method 2: when the gap is comparable to the diameter of the filler material

This is probably the simplest and most convenient method to implement, since the filler material falls into the gap and the welded surface is quite flat. Burn through of the material is minimized since most of the electric arc energy is used to melt the filler material. Otherwise, the process duplicates method 1: welding is carried out with the main electrode by moving it transversely between the edges of the parts being welded.

Method 3: the gap is equal to two diameters of the filler material

In this case, we weld filler material to one edge of the material being welded over the entire length of the gap, and then place the rest of it between the previously welded filler material and the second edge of the parts being welded. Next, after igniting the arc with the main electrode, we make transverse movements between the edges over two strips of filler material.

Method 4: Gap exceeds two filler material diameters

In such a situation, we weld the filler material to both edges to be welded, then place it in the remaining gap and weld with the main electrode, moving it in the transverse direction from edge to edge, but already above the three strips of filler material. Of course, such a case requires more attention and some skill from the welder.

Welding electrodes for general purposes on AliExpress at a discount - http://alii.pub/606j2h

Watch the video

Similar master classes