How to reliably insulate garage doors

In cold weather, heating a garage with uninsulated gates is completely useless: all the heat will escape through them. It is not at all difficult to insulate garage doors using penoplex insulation and sheets of OSB-3 boards in just a few hours. Any adult who has an idea of this type of activity can cope with such work.

Will need

Materials:

- garage lock model RIF-1;

- Penoplex insulation 50 mm thick;

- sheets of OSB-3 boards 9 mm thick;

- polyurethane foam;

- remains of wooden blocks;

- self-tapping screws with press washers.

Tools: brush, gas torch, grinder, hammer, drill, hand-held circular saw, clamps.

The process of insulating swing garage doors with a penoplex wicket and OSB-3 boards

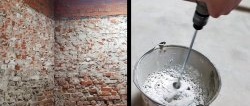

Garage doors made of steel 3 mm thick and edged with a 50x50 mm corner can be insulated in different ways. For this we will use penoplex insulation with low thermal conductivity, zero water absorption, durability and the ability to retain its properties throughout its entire service life. For the finishing sheathing of the insulation we use sheets of OSB-3 boards.

We open the gate wide and clean it with a stiff brush.To remove icing, if found, use a gas burner. We cut off the old lock with a grinder to speed up the work.

The width of one gate leaf turned out to be exactly 124 cm, so there is no need to unravel the insulation sheets. We lay 2 sheets and still have 0.5 cm left for treatment with polyurethane foam.

Before using foam on the insulation, it is necessary to install embeds in the form of remnants of wooden blocks, treated twice with an antiseptic. To do this, drill holes with a diameter of 3 mm in the shelves of the corners. You can also install metal mortgages using welding.

We cut the bars into pieces of 20-30 cm and secure them with self-tapping screws with press washers so that they fit into the bars themselves and do not crack. For ease of fastening, we use clamps.

We use winter foam with minimal expansion, and since the gate is wet, the foam will have excellent adhesion and everything will stick tightly. Working with penoplex is convenient and quick without any dust or dirt.

When heating a garage, condensation will form on the gate due to temperature changes, but it is not dangerous for penoplex, since it is biologically resistant and therefore the appearance of fungi, bacteria and mold is excluded.

Having insulated one gate leaf, we sawed the sheets of OSB-3 boards to size. Next, we coat the insulation sheets a little with foam, apply a sawn-down OSB-3 sheet, and then screw the embedded bars onto the screws. First we fix them with black ones, and then we replace them with galvanized hardware.

The second gate leaf has a wicket, so there is no need to dismantle the insulation sheets. Marking them is very convenient and quick using a tape measure. We set the desired length, hold down the button and simply draw along the sheet, and then use an ordinary stationery knife to make a cut.

Again, using foam, we attach the cut sheets of insulation to the gates and cover them also with cut sheets of OSB-3 boards, screwing them with self-tapping screws.

Before insulating the gate door, we install the lock, aligning it along all the gaps and hooking the bolts onto the tacks. Next, remove the lock, weld the bolts securely, tighten the nuts and check the functionality of the lock.

Using the same scheme, we insulate and sew up the door. We also carefully cover all places and cracks with foam to ensure maximum tightness. Immediately the garage became much warmer, and the door from the inside became noticeably more attractive.

Next, we cover the slopes with the remaining insulation, and with the onset of warm weather, the gate can be painted and an additional plate can be welded on top of the door to hide the hole from the old lock.

Watch the video

Similar master classes