How to make a duplicate key by casting at home

It will be possible to cast a second copy of the door lock key using modeling clay as a mold if you take some low-melting metal - tin, lead or, perhaps, an aluminum alloy.

Making a duplicate key by casting your own hands

From one edge of a block of wood or wood materials, we glue together 2 identical formworks with superglue to make a mold for casting a key from small blocks of limited length, width and especially height. We carefully degrease the gluing areas to ensure the strength of the joints.

To center the formwork halves in the transverse direction along the center of the long sides of one of them, glue the blocks. To eliminate the mismatch of the halves in the longitudinal direction, we also drill blind holes in the center on the narrow sides located at the edge. We press a dowel into the hole of the half-form block without limiters, which, entering the hole of the other half-form, additionally fixes them.

Divide the portion of clay for modeling in half and, after kneading it thoroughly, place it in half-moulds on stretch film.

Carefully fill the corners and make sure that there are no air bubbles left inside the clay.

After filling and leveling the surface of the clay in the molds, cover them with stretch film. Place the original key on the clay in a half-mold with side stops and press it into the clay to about half its thickness. Then cover with the second half-form, press down with your hands, and then with clamps until it stops.

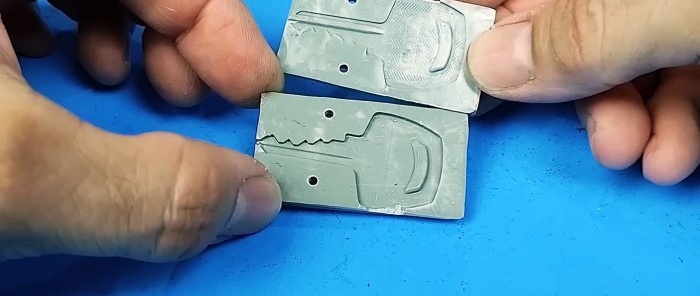

We remove the clay squeezed out of the cracks between the half-forms, as well as the stretch film from the outside. We squeeze the ends of the bars with half-forms, cut off the flash around the perimeter, separate the halves and remove the original key.

We fold the halves again, make holes for fixing and a filler hole on the side.

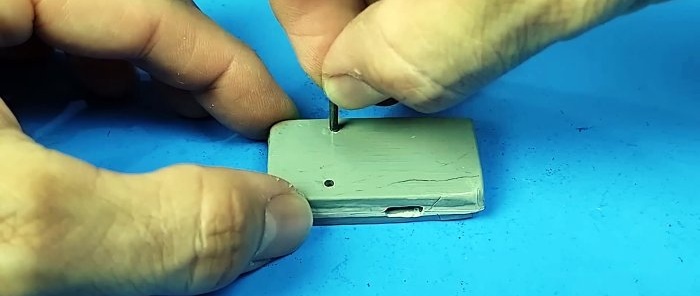

We insert pins into the holes of the half-forms, form a funnel of aluminum foil around the filler hole, which we cover from the inside with a layer of modeling clay. To prevent the halves from coming apart, we squeeze them on both sides with paper clips.

In a steel spoon, use a gas burner to melt the low-melting metal and pour it into the mold.

After waiting for some time, we disassemble the mold, first removing the clamps.

On the copy of the key, we cut off the excess metal formed during the pouring process, correct it a little, and we can use the copy to open and close the door lock.