Liquid plastic! Repairing plastics is easy without glue or a soldering iron!

This can be done quickly and without problems using superglue, but if you don’t have it on hand, you can use the chemical welding method.

How to make liquid plastic for repairs

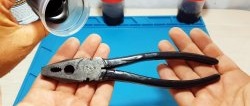

To do this, take an unnecessary piece of plastic and chop it into small pieces with side cutters.

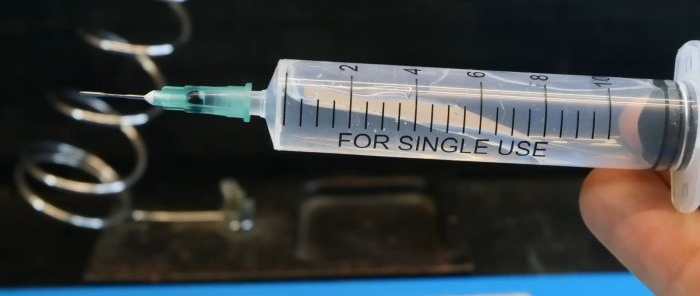

We pour the resulting small particles of plastic into a medical syringe and pour in a certain amount of acetone using a second syringe.

After 2 hours, the acetone will completely dissolve the pieces of plastic and the syringe will contain a colorless liquid with some viscosity.

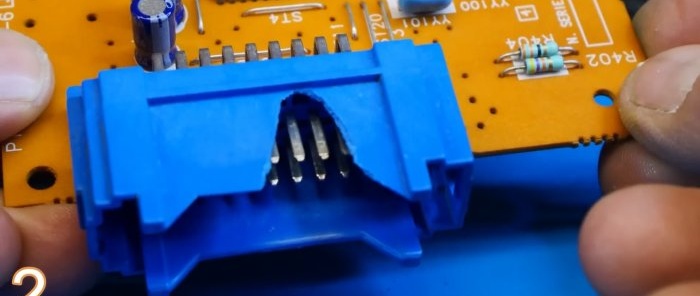

Degrease the surfaces to be glued with a brush dipped in acetone. We connect the parts to be glued and once again coat the joints with acetone on the outside. Then we thickly coat the connection line with a composition from a syringe, representing dissolved plastic in acetone.

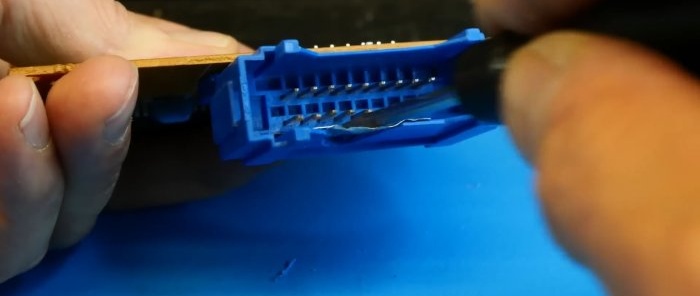

A chipped or broken piece of plastic can be restored using foil tape. We glue a piece of it that is suitable in size on one side of the lost part and carefully smooth it out, pulling the tape.

Pour acetone into a small glass container and dissolve the foam in it.The result is a thick and very sticky mixture.

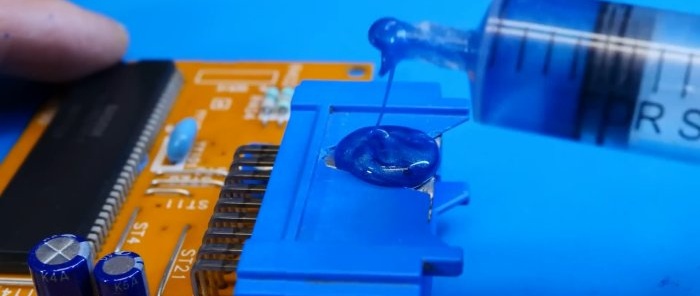

Using a miniature spatula, apply this viscous mixture to the damaged area until the lost part is filled.

After 24 hours of exposure, the applied mixture hardens and is firmly connected to the entire part of the plastic part. Now you can remove the aluminum tape, which played the role of formwork in this operation.

If the plastic part requiring repair is of a certain color, then before restoring the damaged area with a composition of dissolved plastic in acetone, add the appropriate dye to it, mix and fill the damaged area.

A composition of dissolved plastic in acetone can also easily and firmly glue wood pieces.