We solder aluminum

There are situations when it is necessary to solder aluminum products. But due to the fact that the oxide film covers the surface of the aluminum, the solder simply does not stick to it. Solders and fluxes have now been developed specifically for this purpose. But we will try to cope with this task in the old fashioned way.

Attention! Work should be done in a well-ventilated area, preferably equipped with active ventilation, or outdoors.To solder aluminum, we need machine oil (used to lubricate sewing machines), a small piece of sandpaper, rosin and regular solder for soldering radio components.

You need a soldering iron that is as powerful as possible. For example, this one. Its power is 65 W.

We will solder the bottom of an aluminum beer can.

Before work, the soldering iron tip must be leveled with a file (remove all shells) and tinned.

Use a piece of sandpaper to clean the soldering area until it shines.

Pour some oil on this place.

Next, rub the oil stain with sandpaper.

By doing this, we remove the oxide film, and the oil prevents the formation of a new film.

The soldering iron should be warmed up to operating temperature by this time.

We dip the soldering iron tip into rosin, pick up as much solder as possible, dip it into rosin again and begin to quickly rub the future soldering area with little effort. At the same time, the oil begins to burn out profusely. Therefore, we do not regret rosin. If everything was done correctly, then a layer of tin should cover the surface of the aluminum.

Sometimes, to achieve the desired result, you will need to repeat this operation several times.

Copper wire is soldered to tinned aluminum very easily.

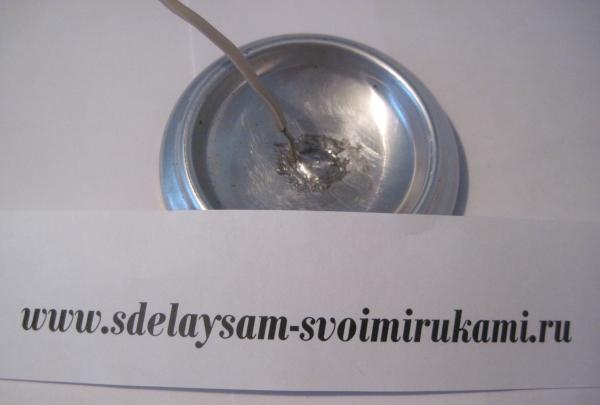

Now let's try to tin and solder the aluminum wire. We remove the insulation from it and clean it until it shines. Pour machine oil onto the tinned bottom of the jar.

Next, the wire needs to be dipped in oil and rubbed with sandpaper.

Then we try to tin the wire right in the bottom of the can. If it works, then everything was done correctly. If not, we work again with sandpaper.

The wire is also perfectly soldered to the aluminum can.

Instead of machine oil, you can use gun oil. If the aluminum part is large, it may need to be heated additionally. For example, on an electric stove.