DIY modern computer desk

Personal workspace largely determines the quality of the work performed, because it determines how comfortable and productive the work process will be. To a large extent, this applies to the desktop, which should be user-friendly. Constructors and designers involved in the development of office and home furniture, offer many original ideas, but you can try to bring your own ideas into reality on your own.

Before you start working on your own project, you should familiarize yourself with the offers on the furniture market, from which you can pick up many interesting ideas. Let's take the IKEA hypermarket as a platform for finding inspiration, where there is always a huge selection of products from different price categories. The work tables available in the catalog of the largest furniture retailer look laconic and high-quality, but lack any special “zest.”

Other manufacturers are doing no better - either the design frankly “smacks” of the last century, or the design is too bulky for modern interiors. However, among all the variety there are also original models that are not overloaded with unnecessary parts and are easy to use. For example, a tabletop adapted to accommodate a laptop, tablet and other gadgets looks very stylish and ergonomic, but not all users can afford its price. However, this is not yet a reason to refuse the table you like, because you can build something similar with your own hands.

The first thing you should decide on at the design stage is the functionality of the future table. Among the proposed options may be placement on the tabletop of a contactless phone charger, a built-in pilot with an extension cord passed through the table leg, areas for a marker board and glass for notes, holes for different types of gadgets, and much more.

For our future table, we will focus on the following functional elements and details:

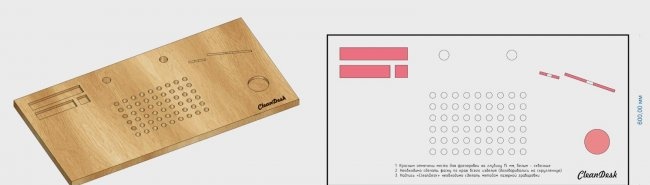

Having decided on the list of necessary functions, you can begin to draw up working drawings according to which our table will be manufactured. For greater convenience, you should use useful computer programs - SketchUp and CorelDraw.These software products allow you to make not only technically competent drawings, but also create three-dimensional 3D models of the future work area.

After drawing up a virtual layout, an idea may come to mind to use a ready-made, inexpensive table, for example, from the same IKEA, to implement it. However, this trick will not work, since almost all inexpensive countertops are hollow inside, and it is technically impossible to make the necessary grooves and holes in them.

Another option is to purchase a shield of specified dimensions (1200 mm x 600 mm x 40 mm), made from solid wood. Here we need to understand that not all tree species are suitable for our purposes. For example, pine will be too soft for a countertop, as a result of which chips and cracks may appear on its surface during processing. To prevent this from happening, experts recommend choosing hard wood types such as beech, oak and ash.

Next comes the most difficult stage of making a table - finding a company engaged in milling and laser engraving of wood. Despite the apparent simplicity of the task, not all craftsmen are ready to undertake it, so you will have to spend time finding craftsmen who will not “raise” the price for their services to the cosmic level. We managed to find such wonderful guys who, moreover, helped with finalizing the project and gave useful recommendations and advice.

After all the holes, grooves and recesses have been implemented according to the original plan, the tabletop must be processed accordingly to bring it into working order.First, all surfaces are sanded using sandpaper, including the inside of the holes. To achieve perfect smoothness, you will need different types of sandpaper grit - 100, 280 and 360. The manual sanding process can take several hours, as it requires special care when performing.

After obtaining a smooth surface without roughness and burrs, you can begin the final processing of the wood. To do this, you can use varnish, paint or oil, depending on the user’s personal preferences. We chose the latter option, inspired by the numerous benefits of the oil:

In addition, applying even several layers of oil does not form a glossy film visible to the eye on the surface and does not give a cloying shine.

Each layer of oil coating should be dried for two hours, after which you can begin installing the support legs. For our model, we used ready-made IKEA legs, and installing them was perhaps the easiest step in the whole idea of making a table.

One month was spent on implementing the idea “from scratch”, during which the following tasks were consistently implemented:

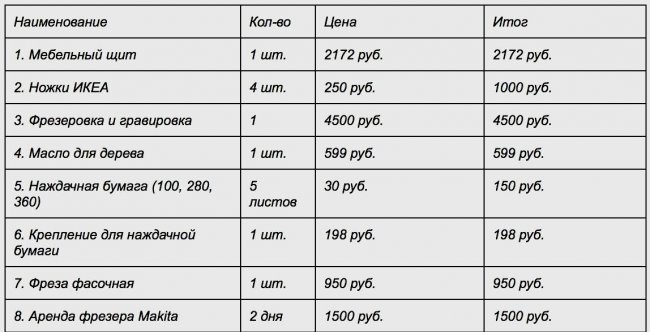

In terms of price, the most expensive aspects were milling and engraving services, as well as the purchase of furniture panels made from solid wood. All other stages were carried out on our own, which ultimately allowed us to keep the total amount to a little more than 10 thousand rubles.

The experience gained in independently manufacturing a modern computer desk allowed us to draw a number of important practical conclusions:

Using these tips, you can try your own hand at making other types of furniture that will fully satisfy all your needs and requirements.

After some time, I corrected the mistakes I had made and made another table, but from beech. This is pre-purchased material:

And here is the table itself, marked version 2.0.

source

What do manufacturers offer?

Before you start working on your own project, you should familiarize yourself with the offers on the furniture market, from which you can pick up many interesting ideas. Let's take the IKEA hypermarket as a platform for finding inspiration, where there is always a huge selection of products from different price categories. The work tables available in the catalog of the largest furniture retailer look laconic and high-quality, but lack any special “zest.”

Other manufacturers are doing no better - either the design frankly “smacks” of the last century, or the design is too bulky for modern interiors. However, among all the variety there are also original models that are not overloaded with unnecessary parts and are easy to use. For example, a tabletop adapted to accommodate a laptop, tablet and other gadgets looks very stylish and ergonomic, but not all users can afford its price. However, this is not yet a reason to refuse the table you like, because you can build something similar with your own hands.

Drawing up an engineering project

The first thing you should decide on at the design stage is the functionality of the future table. Among the proposed options may be placement on the tabletop of a contactless phone charger, a built-in pilot with an extension cord passed through the table leg, areas for a marker board and glass for notes, holes for different types of gadgets, and much more.

For our future table, we will focus on the following functional elements and details:

- central holes for removing wires from the laptop and additional passive cooling;

- deep recess for a coffee cup;

- places to place a tablet and smartphone with holes for connecting a charger;

- small stands for various small things - pencils, pens, flash drives, etc.

Having decided on the list of necessary functions, you can begin to draw up working drawings according to which our table will be manufactured. For greater convenience, you should use useful computer programs - SketchUp and CorelDraw.These software products allow you to make not only technically competent drawings, but also create three-dimensional 3D models of the future work area.

Prototype making

After drawing up a virtual layout, an idea may come to mind to use a ready-made, inexpensive table, for example, from the same IKEA, to implement it. However, this trick will not work, since almost all inexpensive countertops are hollow inside, and it is technically impossible to make the necessary grooves and holes in them.

Another option is to purchase a shield of specified dimensions (1200 mm x 600 mm x 40 mm), made from solid wood. Here we need to understand that not all tree species are suitable for our purposes. For example, pine will be too soft for a countertop, as a result of which chips and cracks may appear on its surface during processing. To prevent this from happening, experts recommend choosing hard wood types such as beech, oak and ash.

Next comes the most difficult stage of making a table - finding a company engaged in milling and laser engraving of wood. Despite the apparent simplicity of the task, not all craftsmen are ready to undertake it, so you will have to spend time finding craftsmen who will not “raise” the price for their services to the cosmic level. We managed to find such wonderful guys who, moreover, helped with finalizing the project and gave useful recommendations and advice.

Tabletop processing stage

After all the holes, grooves and recesses have been implemented according to the original plan, the tabletop must be processed accordingly to bring it into working order.First, all surfaces are sanded using sandpaper, including the inside of the holes. To achieve perfect smoothness, you will need different types of sandpaper grit - 100, 280 and 360. The manual sanding process can take several hours, as it requires special care when performing.

After obtaining a smooth surface without roughness and burrs, you can begin the final processing of the wood. To do this, you can use varnish, paint or oil, depending on the user’s personal preferences. We chose the latter option, inspired by the numerous benefits of the oil:

- absence of harmful fumes, environmental friendliness;

- resistance to high temperatures and moisture;

- quick drying in a few hours;

- preservation of the natural structure of the wood surface;

- ease of use and subsequent operation.

In addition, applying even several layers of oil does not form a glossy film visible to the eye on the surface and does not give a cloying shine.

Each layer of oil coating should be dried for two hours, after which you can begin installing the support legs. For our model, we used ready-made IKEA legs, and installing them was perhaps the easiest step in the whole idea of making a table.

Summarizing

One month was spent on implementing the idea “from scratch”, during which the following tasks were consistently implemented:

- 1 week - drawing up your own ideas, creating a list of necessary functions, drawing up ideas about the appearance of the future table;

- Week 2 - making a 3D model and drawings using computer programs, searching for suitable craftsmen who are professionally involved in milling;

- Week 3 - performing milling and engraving work;

- Week 4 - finishing work on the tabletop, installing the legs.

In terms of price, the most expensive aspects were milling and engraving services, as well as the purchase of furniture panels made from solid wood. All other stages were carried out on our own, which ultimately allowed us to keep the total amount to a little more than 10 thousand rubles.

The experience gained in independently manufacturing a modern computer desk allowed us to draw a number of important practical conclusions:

- It is difficult to find a suitable desktop model in retail sales;

- when purchasing furniture panels for a tabletop, you need to give preference to hard types of wood;

- when searching for milling cutting services, you may encounter difficulties;

- Oil finish is a good finish for wood.

Using these tips, you can try your own hand at making other types of furniture that will fully satisfy all your needs and requirements.

After some time, I corrected the mistakes I had made and made another table, but from beech. This is pre-purchased material:

And here is the table itself, marked version 2.0.

source

Similar master classes

Particularly interesting

Comments (1)