How to make a charger for 10 batteries

They asked me to make a charger. The main difference from many is the presence of 10 channels. People are going to charge a number of lead batteries. They have batteries installed in laser tag weapons. This charger can also be used to charge Li-ion.

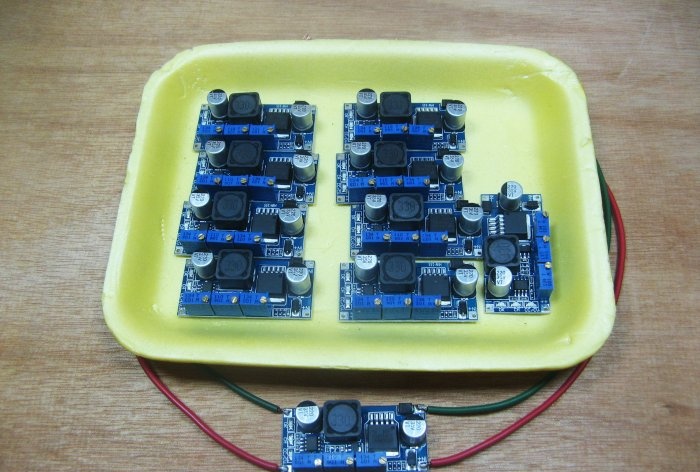

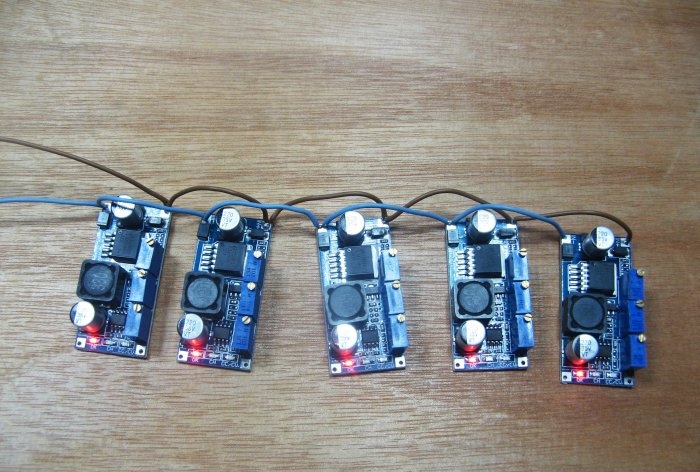

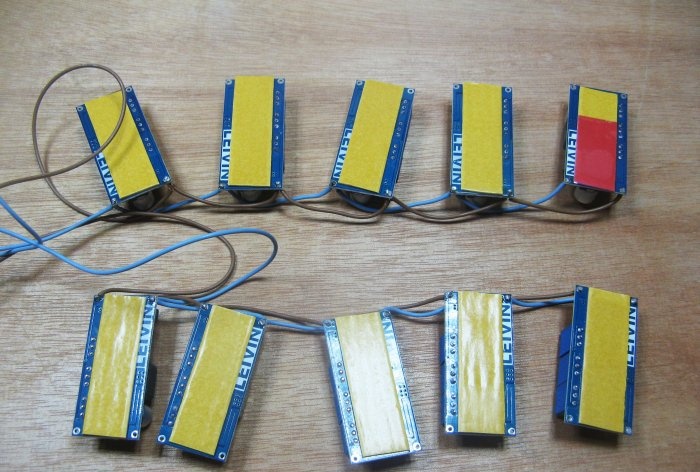

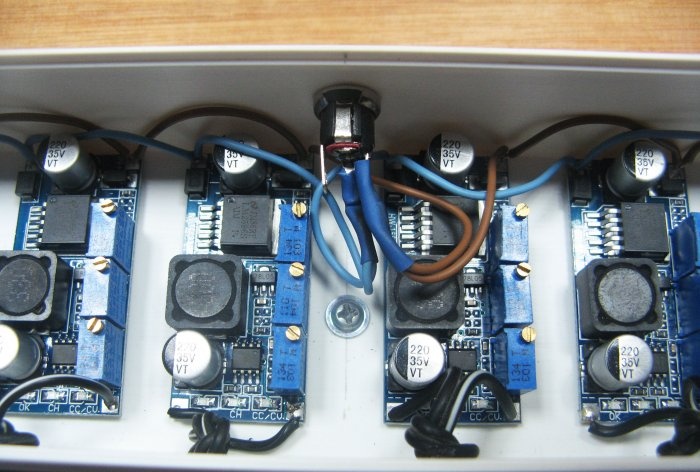

You need to connect all the boards together. I used soft wire. We combine all the pros with each other, and we also combine all the cons.Having soldered 5 boards, I checked them. They are working.

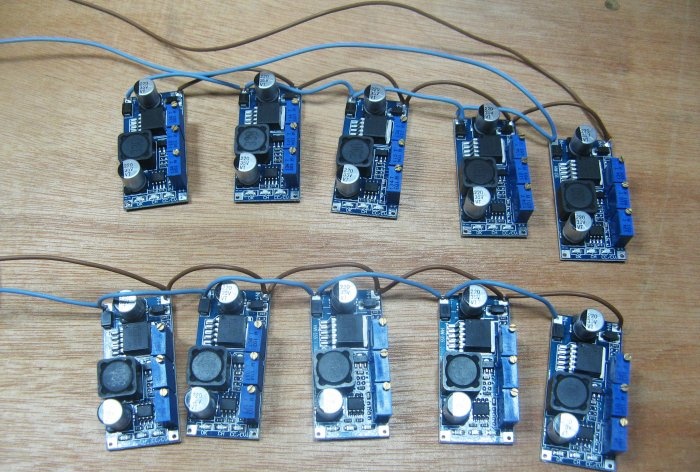

We connect all 10 boards parallel to each other.

We glue with double-sided tape. Its thickness is about 1 mm.

I cut these plugs out of plastic. They will be attached with super glue, nothing military here. They lean against the box and coat it with glue.

To ensure the reliability of the structure, I took a piece of plywood. I'll screw the box to it.

I made holes in the plywood on the sides to mount the device on the wall.

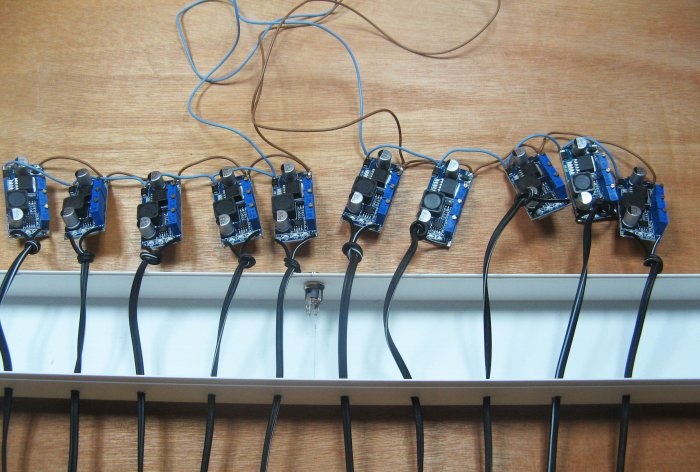

I make holes in the side of the box for the wires.

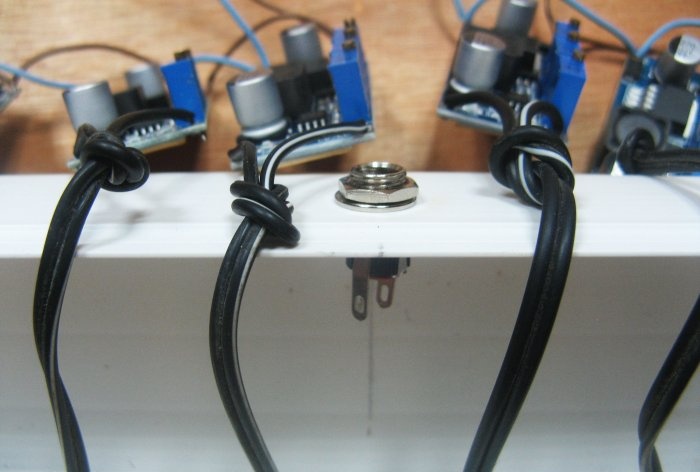

I feed the wires through the holes in the box, tying knots on the wires. I solder the wires to the boards according to the polarity. In the center there is a plus, the outer cylinder is a minus.

I installed a connector on the box. An external power source is connected through it. I connected 12.6 volts. More is possible, but this device can be connected in the car.

I solder the external connector.

I almost forgot the main thing. The batteries in vending machines are 6 volt. The boards are set to 7.3 volts, with the resistor closest to the incoming connector. The current is adjusted to 0.12 amperes. The resistor closest to the output connectors. I didn’t turn on the charge control indicator; there was no need for it. I turn it on. Everything is working.

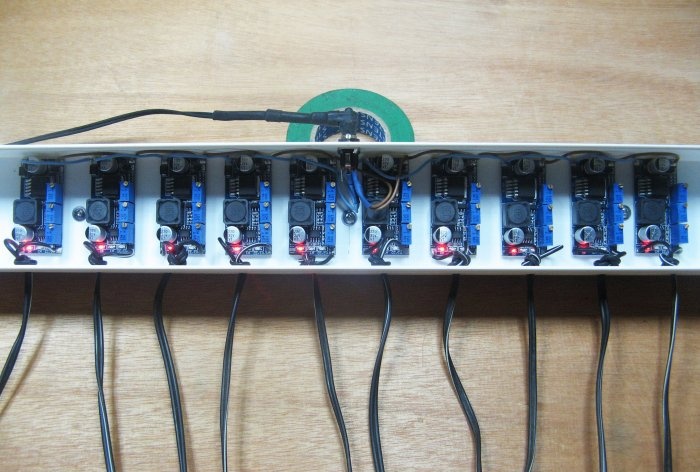

This is what the finished device looks like. So far I have installed 10 boards. If necessary, you can add four more; there is space for them. Close the lid.

This is such a simple charger. People were pleased with the result. This device can charge any batteries. The main thing is to configure the necessary parameters.

For homemade we need

- To mount the device, I chose a wiring box. The dimensions of the casing are 4*6 cm. A piece of half a meter was needed.

- Since they gave me the old connectors, I will install them in the new design.

- You will also need double-sided tape. I took the foam one.

- For the casing plugs I used soft plastic. It seems like there are factory plugs, but I haven’t found any.

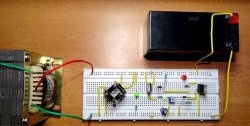

- The basis of our charging is LM2596 boards from China (http://ali.pub/3ge64l). They have resistors to regulate voltage and current. There is also a resistor for setting the end of charge indication.

- You also need a connector for connecting an external power supply. At the time of assembly. Its type has not yet been determined.

Assembly of the structure

You need to connect all the boards together. I used soft wire. We combine all the pros with each other, and we also combine all the cons.Having soldered 5 boards, I checked them. They are working.

We connect all 10 boards parallel to each other.

We glue with double-sided tape. Its thickness is about 1 mm.

I cut these plugs out of plastic. They will be attached with super glue, nothing military here. They lean against the box and coat it with glue.

To ensure the reliability of the structure, I took a piece of plywood. I'll screw the box to it.

I made holes in the plywood on the sides to mount the device on the wall.

I make holes in the side of the box for the wires.

I feed the wires through the holes in the box, tying knots on the wires. I solder the wires to the boards according to the polarity. In the center there is a plus, the outer cylinder is a minus.

I installed a connector on the box. An external power source is connected through it. I connected 12.6 volts. More is possible, but this device can be connected in the car.

I solder the external connector.

I almost forgot the main thing. The batteries in vending machines are 6 volt. The boards are set to 7.3 volts, with the resistor closest to the incoming connector. The current is adjusted to 0.12 amperes. The resistor closest to the output connectors. I didn’t turn on the charge control indicator; there was no need for it. I turn it on. Everything is working.

This is what the finished device looks like. So far I have installed 10 boards. If necessary, you can add four more; there is space for them. Close the lid.

This is such a simple charger. People were pleased with the result. This device can charge any batteries. The main thing is to configure the necessary parameters.

Watch the video

Similar master classes

Particularly interesting

Comments (0)