Jet stove from a gas cylinder

Heating devices are used not only in residential but also in industrial premises. There are a great many modifications of them, because the conditions in workshops are usually not sophisticated. Therefore, they install everything that is affordable and economical - from potbelly stoves to technically sophisticated heating systems.

Today we offer for consideration one of the most interesting stove models. A rocket stove or jet stove is fundamentally different from others in the high degree of heating and convection of the body, which is made either of bricks (stone stove) or of thick-walled metal. This heating device is equipped with a water circuit, connected to radiators and you get an almost complete economical heating system.

The author of the homemade product suggests making our version of a jet stove from an empty propane cylinder. A small modernization, a minimum of parts and you have an excellent option for a heating furnace for a production workshop!

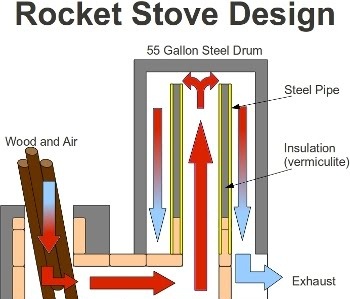

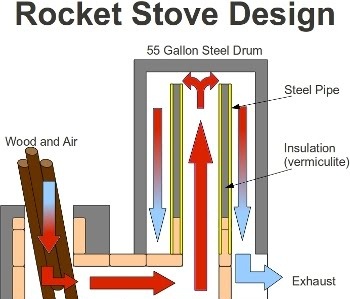

The stove consists of a firebox, a heated container and a chimney. The firebox is made in the form of a curved pipe, in which firewood burns in its lower part.Hot air rises through a vertical pipe located in the center of the heated container, which in our case is made of a gas cylinder. Rising upward, hot air heats the walls of the container, and gradually cooling down, it exits at the bottom through the chimney, which creates air convection and draft in the oven.

Materials:

Tools:

Before you get to work, you must remember that gas cylinders are extremely flammable and explosive. They must be thoroughly rinsed with water that has been left in a cylinder for a while, since even small residues of liquefied gas during cutting can lead to an explosion of the container.

A household propane cylinder consists of a neck, a shell and a bottom. It is usually positioned vertically, so that the shut-off valve remains in the most visible place in the center of the cylinder. You need to get rid of it by lightly tapping it with a hammer.

After unscrewing the fitting with an open-end wrench, fill the cylinder with water to wash off the remaining liquefied gas. Let the water sit for a while, and then carefully tip the container over and drain it. Even after such measures, we carefully transfer the cylinder to the treatment site. Using a plasma cutter, cut off the bottom of the cylinder.

The next step is to cut the metal corners to the size of the loading chamber, firebox and air duct. We cut them with a grinder or plasma cutter, and boil each of them along the ribs.

The connections will be located at different angles. The dimensions of these elements are as follows:

The firebox and air duct are connected perpendicularly. We cut the ends of these pipes at a miter angle of 45 degrees, and weld them on all sides of the pipe. Since the metal heats up over 1500 degrees Celsius during the welding process, it can lead. Therefore, it would be a good idea to check the accuracy of the connection with a metal corner.

The location of the loading chamber will be inclined, so the feeder pipe must be cut at an angle of less than 45 degrees. We place it on the fuel pipe a few centimeters from the edge of the firebox, where the ash pan will subsequently be located. Using the marking of the pipe section, we make a slot at the junction of the elements and weld it in place.

The firebox must be level and securely fastened. It will be supported by a small piece of corner from which the pipes were made. We cut it exactly to size and place it on the bottom of the cylinder, checking the identity of the straight line between the planes of the cylinder with a metal corner.

We boil the firebox, reinforcing the vertical air duct pipe with metal plates or corners. We mark a seat for it on the wall of the cylinder, and make a slot with plasma or a grinder. The more precise the cut is, the easier it is to scald it later.

We position the firebox so that the vertical pipe inside the cylinder is located strictly in the center. We use a welding machine to weld the bottom and the firebox pipe.

A regular bolt or similar piece of metal will help plug the hole at the top of the cylinder. We insert it into the hole and weld it to the cylinder. You can clean the seam with a sanding disc and grinder.

At the bottom of the cylinder, on the opposite side of the firebox, we install a chimney. We mark the fitting hole of the pipe with a marker, cut out a circle in the wall of the cylinder, and scald it along the contour.

We close the ash pan with a removable lid with a thermally insulating handle. For convenience, it can be attached to hinges. It will be most convenient to light wood in the stove through this hole.

We take the pipe outlet outside the workshop. The higher the chimney pipe, the better the draft in the stove. Now your workshop will always be warm and cozy all year round!

Today we offer for consideration one of the most interesting stove models. A rocket stove or jet stove is fundamentally different from others in the high degree of heating and convection of the body, which is made either of bricks (stone stove) or of thick-walled metal. This heating device is equipped with a water circuit, connected to radiators and you get an almost complete economical heating system.

The author of the homemade product suggests making our version of a jet stove from an empty propane cylinder. A small modernization, a minimum of parts and you have an excellent option for a heating furnace for a production workshop!

Operating principle of the furnace

The stove consists of a firebox, a heated container and a chimney. The firebox is made in the form of a curved pipe, in which firewood burns in its lower part.Hot air rises through a vertical pipe located in the center of the heated container, which in our case is made of a gas cylinder. Rising upward, hot air heats the walls of the container, and gradually cooling down, it exits at the bottom through the chimney, which creates air convection and draft in the oven.

Materials:

- Propane gas cylinder;

- Square pipe welded from paired corners;

- Metal corner 50x50x5 mm;

- Round chimney pipe with swivel elbows;

- Auxiliary metal elements: plates, corner trims, plugs.

Tools:

- For metal cutting: inverter plasma cutter or grinder with stripping and cutting discs;

- Welding machine;

- Metal straight corner, tape measure, marker for marking;

- Bubble level, hammer, metal brush.

Making a rocket stove

Before you get to work, you must remember that gas cylinders are extremely flammable and explosive. They must be thoroughly rinsed with water that has been left in a cylinder for a while, since even small residues of liquefied gas during cutting can lead to an explosion of the container.

Preparing the balloon

A household propane cylinder consists of a neck, a shell and a bottom. It is usually positioned vertically, so that the shut-off valve remains in the most visible place in the center of the cylinder. You need to get rid of it by lightly tapping it with a hammer.

After unscrewing the fitting with an open-end wrench, fill the cylinder with water to wash off the remaining liquefied gas. Let the water sit for a while, and then carefully tip the container over and drain it. Even after such measures, we carefully transfer the cylinder to the treatment site. Using a plasma cutter, cut off the bottom of the cylinder.

We cut the pipes and scald the firebox

The next step is to cut the metal corners to the size of the loading chamber, firebox and air duct. We cut them with a grinder or plasma cutter, and boil each of them along the ribs.

The connections will be located at different angles. The dimensions of these elements are as follows:

- Vertical air duct – 900 mm;

- Horizontal firebox – 500 mm;

- Feeder or loading chamber – 400 mm.

The firebox and air duct are connected perpendicularly. We cut the ends of these pipes at a miter angle of 45 degrees, and weld them on all sides of the pipe. Since the metal heats up over 1500 degrees Celsius during the welding process, it can lead. Therefore, it would be a good idea to check the accuracy of the connection with a metal corner.

The location of the loading chamber will be inclined, so the feeder pipe must be cut at an angle of less than 45 degrees. We place it on the fuel pipe a few centimeters from the edge of the firebox, where the ash pan will subsequently be located. Using the marking of the pipe section, we make a slot at the junction of the elements and weld it in place.

The firebox must be level and securely fastened. It will be supported by a small piece of corner from which the pipes were made. We cut it exactly to size and place it on the bottom of the cylinder, checking the identity of the straight line between the planes of the cylinder with a metal corner.

We boil the firebox, reinforcing the vertical air duct pipe with metal plates or corners. We mark a seat for it on the wall of the cylinder, and make a slot with plasma or a grinder. The more precise the cut is, the easier it is to scald it later.

We position the firebox so that the vertical pipe inside the cylinder is located strictly in the center. We use a welding machine to weld the bottom and the firebox pipe.

A regular bolt or similar piece of metal will help plug the hole at the top of the cylinder. We insert it into the hole and weld it to the cylinder. You can clean the seam with a sanding disc and grinder.

Installing a chimney

At the bottom of the cylinder, on the opposite side of the firebox, we install a chimney. We mark the fitting hole of the pipe with a marker, cut out a circle in the wall of the cylinder, and scald it along the contour.

We close the ash pan with a removable lid with a thermally insulating handle. For convenience, it can be attached to hinges. It will be most convenient to light wood in the stove through this hole.

We take the pipe outlet outside the workshop. The higher the chimney pipe, the better the draft in the stove. Now your workshop will always be warm and cozy all year round!

Watch the video

Similar master classes

Particularly interesting

Comments (2)