How to make a water pump from PVC pipes

The irrigation and water supply system in summer cottages is vital. Without good watering and irrigation of crops, even on fertile land, it is unlikely that anything will grow. And the water pump is the main element of such a system. It automates the movement of water, converting mechanical energy into fluid flow energy designed to move it. Many people use such machines in their dachas, and without them they can no longer imagine success in their business. But what about those who have not yet used such devices and are just wondering which one to use?

Perhaps a vertical type axial propeller pump is suitable for you. This device is extremely simple, and even a beginner who knows nothing about technology can make it. But the benefits from it can be enormous, because it is capable of pumping water quite intensively from one place to another.

Suppose you have a storage tank with rainwater on your site, into which water is collected on the passive side after rains. Carrying it in buckets is tedious, and moving it is not at all possible.This is where the homemade product that we will look at today comes in handy - a simple and effective axial pump, assembled literally from nothing. And this is not a typo, because the cost of its components is less than $10. Can't this be? We invite you to check this with us.

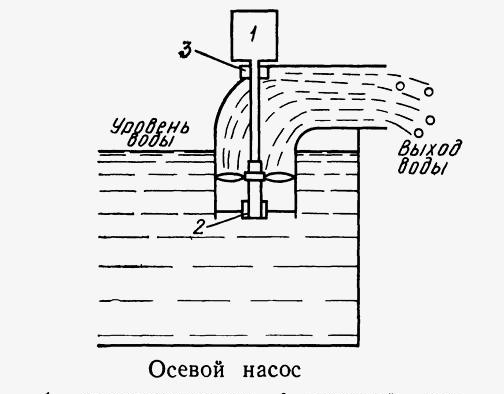

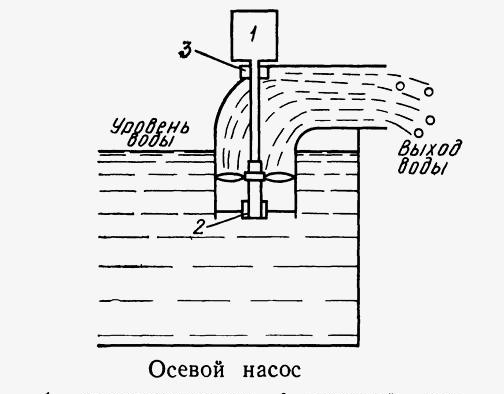

The plastic tube is the pump body. Inside it there is an axis with one impeller, which acts as a guide for the axial flow of the pumped liquid. The propeller blades create a vortex flow like a fan, changing the pressure inside the pipe. Water from the bottom is drawn into the tube and moves under pressure to the free side outlet.

Such rigid vane single-stage pumps do not have dry suction and have a low permissible vacuum suction lift. The operation of the pump is based on the change in pressure between two media of different densities - water and air.

To ensure cavitation-free operation, these pumps are placed below the free level of the pumped liquid, i.e. The pump impeller must be constantly in water.

Necessary materials:

Tools:

For the pump body we will need a PVC pipe and tee. We cut two lengths of 25 and 6 cm from the pipe. We connect these pipes with a tee as shown in the photo.

We mark a metal plate about 1 cm wide in the center. We make a hole for the shaft or axle. We cut the plate along the contour of the inner circumference of the pipe.

We make the pump axis from a bicycle spoke. The metal is hard and the surface is corrosion-resistant. At the other end, the spoke has a bend for mounting on a bicycle rim. We bite off this bend with pliers and place a small adapter for the motor shaft on it. We fix it on the knitting needle with solder.

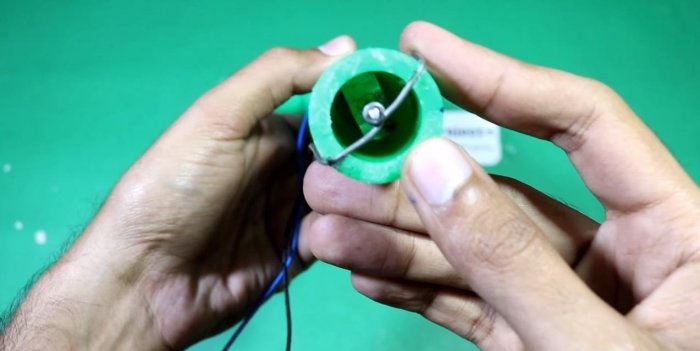

We place the impeller on the pump axis, moving 3-4 cm from the end. We fix the impeller by soldering it on both sides with a soldering iron. We give the blades the shape of a propeller.

The engine fixed in the upper branch of the tee must be isolated from water. To do this, we cut out a small gasket from plexiglass according to the size of the outer circumference of the PVC pipe. We attach this element to the engine with hot glue, leaving only the area of its shaft open.

We place the pump axis on the engine shaft. We fix the engine itself through a gasket to a PVC tee using hot glue. At the bottom of the suction pipe we place a distributor made of a piece of aluminum wire to eliminate swirling of the flow.

We solder the copper contacts to the engine. They can be additionally insulated with heat shrink. We connect the pump to the battery and place the suction pipe in a container of water.

Now your site will not be left without watering and irrigation, because you have an excellent and quite powerful device for pumping water. Anyone can make it, and the cost of components will not burden the budget of even pensioners or novice gardening enthusiasts!

Perhaps a vertical type axial propeller pump is suitable for you. This device is extremely simple, and even a beginner who knows nothing about technology can make it. But the benefits from it can be enormous, because it is capable of pumping water quite intensively from one place to another.

Suppose you have a storage tank with rainwater on your site, into which water is collected on the passive side after rains. Carrying it in buckets is tedious, and moving it is not at all possible.This is where the homemade product that we will look at today comes in handy - a simple and effective axial pump, assembled literally from nothing. And this is not a typo, because the cost of its components is less than $10. Can't this be? We invite you to check this with us.

Operating principle of an axial pump

The plastic tube is the pump body. Inside it there is an axis with one impeller, which acts as a guide for the axial flow of the pumped liquid. The propeller blades create a vortex flow like a fan, changing the pressure inside the pipe. Water from the bottom is drawn into the tube and moves under pressure to the free side outlet.

Such rigid vane single-stage pumps do not have dry suction and have a low permissible vacuum suction lift. The operation of the pump is based on the change in pressure between two media of different densities - water and air.

To ensure cavitation-free operation, these pumps are placed below the free level of the pumped liquid, i.e. The pump impeller must be constantly in water.

We make a water pump

Necessary materials:

- A piece of PVC pipe 32 mm, length – 35-40 cm;

- PVC connecting tee 32 mm;

- 12V DC motor;

- Bicycle spoke;

- Metal plate;

- 12 V battery;

- Heat-shrinkable casings;

- A small piece of plexiglass and copper wiring.

Tools:

- Soldering iron;

- Plumbing soldering iron or iron;

- Hot glue gun;

- Marker, pliers and paint knife.

Making the body

For the pump body we will need a PVC pipe and tee. We cut two lengths of 25 and 6 cm from the pipe. We connect these pipes with a tee as shown in the photo.

Preparing the axle with impeller

We mark a metal plate about 1 cm wide in the center. We make a hole for the shaft or axle. We cut the plate along the contour of the inner circumference of the pipe.

We make the pump axis from a bicycle spoke. The metal is hard and the surface is corrosion-resistant. At the other end, the spoke has a bend for mounting on a bicycle rim. We bite off this bend with pliers and place a small adapter for the motor shaft on it. We fix it on the knitting needle with solder.

We place the impeller on the pump axis, moving 3-4 cm from the end. We fix the impeller by soldering it on both sides with a soldering iron. We give the blades the shape of a propeller.

We connect the engine and assemble the pump

The engine fixed in the upper branch of the tee must be isolated from water. To do this, we cut out a small gasket from plexiglass according to the size of the outer circumference of the PVC pipe. We attach this element to the engine with hot glue, leaving only the area of its shaft open.

We place the pump axis on the engine shaft. We fix the engine itself through a gasket to a PVC tee using hot glue. At the bottom of the suction pipe we place a distributor made of a piece of aluminum wire to eliminate swirling of the flow.

We solder the copper contacts to the engine. They can be additionally insulated with heat shrink. We connect the pump to the battery and place the suction pipe in a container of water.

Now your site will not be left without watering and irrigation, because you have an excellent and quite powerful device for pumping water. Anyone can make it, and the cost of components will not burden the budget of even pensioners or novice gardening enthusiasts!

Watch the video

Similar master classes

Particularly interesting

Comments (7)