How to unscrew a licked screw - 7 ways

The problem of licked edges of a screw for a Phillips screwdriver has long been known to everyone. There are few solutions to how to get out of such a situation and remove a broken screw. I will only offer you seven that I personally had to use.

How to unscrew a licked screw?

Unfortunately, there is no almost universal solution. And each method presented is good for its own situation. Therefore, everything is learned by comparison and applied to a specific individual situation and one’s own situation.

First method: use a tourniquet

You will need a piece of thick rubber. This could be a piece of a medical tourniquet, a piece of an inner tube from a bicycle, or the like. The denser and stiffer the material, the greater the twisting force that can be created.

Berm a screwdriver that is as similar as possible to the groove of the screw.

We take the tourniquet.

We place a tourniquet under a screwdriver or a bit and insert it all into the licked head. Next, with simultaneous pressure and a rotational movement, we try to unscrew the screw.

With the right amount of force, you can unscrew the screw with a significant screw-in force.

Method two: how to remove a screw using an impact screwdriver

If you have an impact driver (or ask a friend), you can use it.

Of course, the screw cannot be completely unscrewed, but the connection can be loosened significantly, and then we use a regular screwdriver.

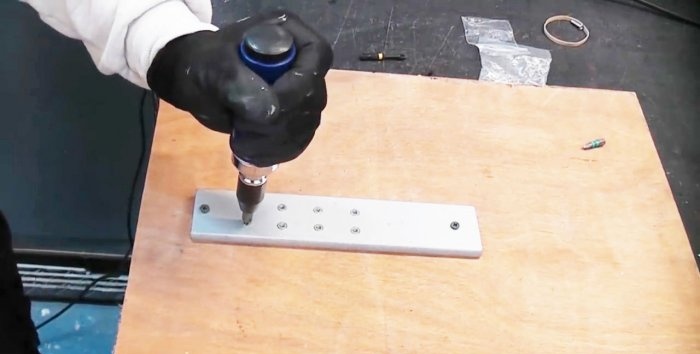

Third method: use a special bit for bolts with ground crosses

Since the problem of slick edges is not new, ready-made solutions have been sold on the market for a long time. For example, a special bit for unscrewing licked bolts.

We insert it into a screwdriver or screwdriver and unscrew it. Sharp edges at the right angle engage perfectly and the screw can be rotated.

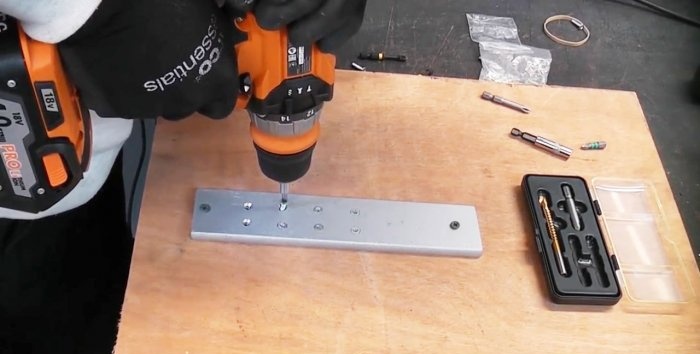

Fourth method: extractor

Special tools designed for repairing broken screws, studs, bolts and the like include an extractor. It works the same as the bit in the example above, but with a slight difference.

Insert the bit into the screwdriver and unscrew it. You may first need to select an extractor based on the recess, since the diameters of the heads vary.

Fifth method: unscrew with the left drill

On sale, in addition to the drills we are all familiar with, there are also drills with a left-handed spiral. Such a drill can be used as a tool for unscrewing a broken screw.

Sixth method: use core

This method is well suited for removing small screws. We take the core, rest it against the edge of the cap at an angle of approximately 45 degrees and gently hit it with a hammer in the direction of rotation of the cap.

The core, due to its sharpness, has good engagement, which means that the screw is more likely to be unscrewed.

Seventh method: take a hammer and chisel

The method has become classic, but using it for small screws is problematic.We take a chisel or chisel, place the tip into the side of the head and gently hit it and turn the screw. The main thing here is to move the cap from its place, and once it appears, unscrewing can be continued with pliers.

Friends, it will be very cool if you share your ways to get out of such a life situation. Thank you for your attention!

Watch the video

For more information, watch the video.

Similar master classes

Particularly interesting

Comments (11)