Automatic cooler speed controller

Cooling fans are now found in many household appliances, be it computers, stereo systems, or home theaters. They do their job well, cool the heating elements, but at the same time they emit a heart-rending and very annoying noise. This is especially critical in stereo systems and home theaters, because fan noise can interfere with enjoying your favorite music. Manufacturers often save money and connect cooling fans directly to the power supply, which makes them always rotate at maximum speed, regardless of whether cooling is currently required or not. You can solve this problem quite simply - build in your own automatic cooler speed controller. It will monitor the temperature of the radiator and only turn on cooling if necessary, and if the temperature continues to rise, the regulator will increase the cooler speed up to the maximum. In addition to reducing noise, such a device will significantly increase the service life of the fan itself. It can also be used, for example, when creating homemade powerful amplifiers, power supplies or other electronic devices.

Scheme

The circuit is extremely simple, containing only two transistors, a couple of resistors and a thermistor, but nevertheless it works great. M1 in the diagram is a fan whose speed will be regulated. The circuit is designed to use standard 12-volt coolers. VT1 – low-power n-p-n transistor, for example, KT3102B, BC547B, KT315B. Here it is advisable to use transistors with a gain of 300 or more. VT2 is a powerful npn transistor; it is the one that switches the fan. You can use inexpensive domestic KT819, KT829, again it is advisable to choose a transistor with a high gain. R1 is a thermistor (also called a thermistor), a key link in the circuit. It changes its resistance depending on the temperature. Any NTC thermistor with a resistance of 10-200 kOhm, for example, the domestic MMT-4, is suitable here. The value of the tuning resistor R2 depends on the choice of thermistor; it should be 1.5 - 2 times larger. This resistor sets the threshold for turning on the fan.

Manufacturing of the regulator

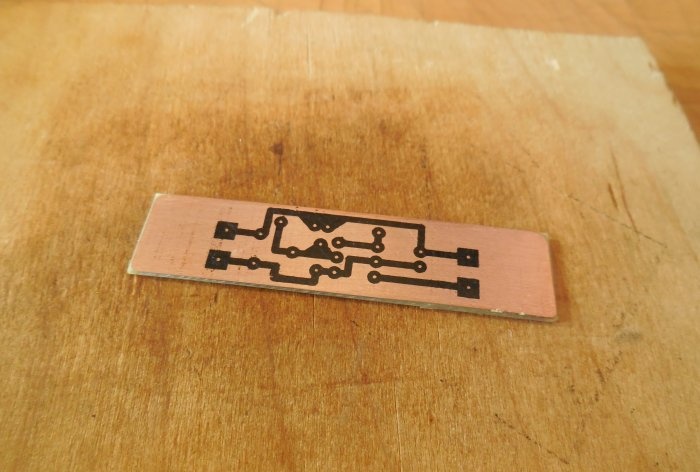

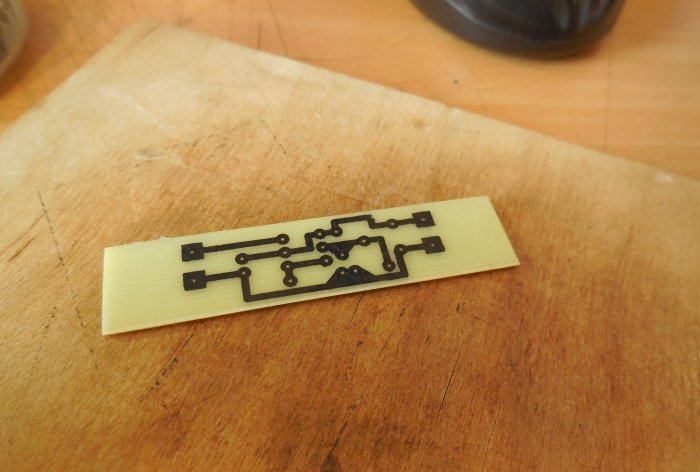

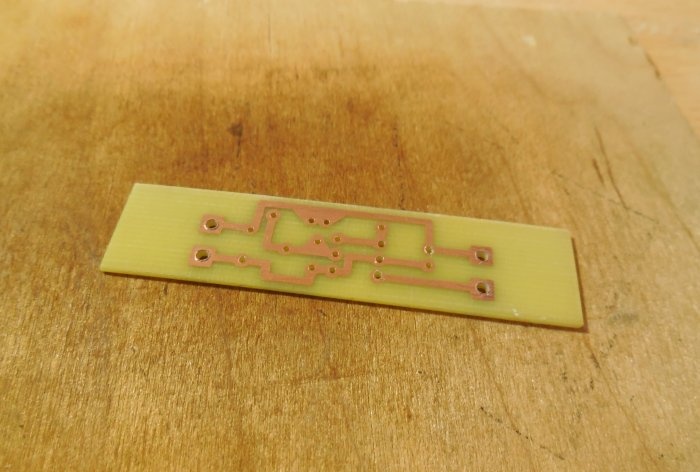

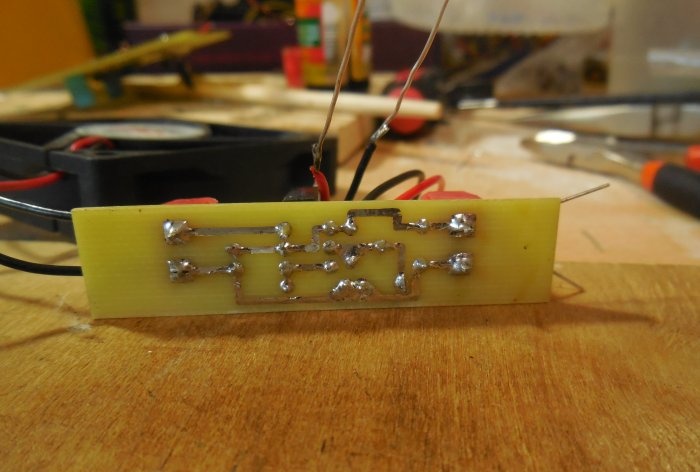

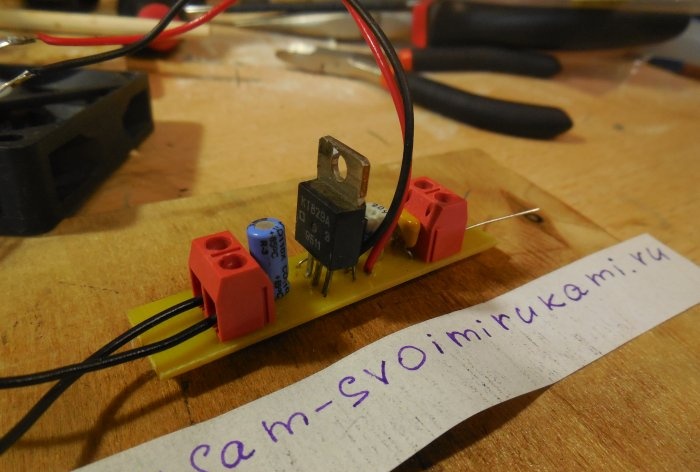

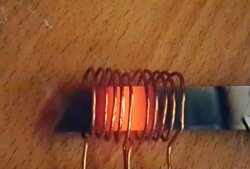

The circuit can be easily assembled using surface mounting, or you can make a printed circuit board, which is what I did. To connect the power wires and the fan itself, terminal blocks are provided on the board, and the thermistor is output on a pair of wires and attached to the radiator. For greater thermal conductivity, you need to attach it using thermal paste. The board is made using the LUT method; below are several photographs of the process.

Download the board:After making the board, parts are soldered into it, as usual, first small, then large. It is worth paying attention to the pinout of the transistors in order to solder them correctly.After completing the assembly, the board must be washed from flux residues, the tracks must be ringed, and the installation must be ensured correctly.

Settings

Now you can connect the fan to the board and carefully supply power by setting the trimming resistor to the minimum position (VT1 base is pulled to ground). The fan should not rotate. Then, smoothly turning R2, you need to find the moment when the fan starts to rotate slightly at minimum speed and turn the trimmer back just a little so that it stops rotating. Now you can check the operation of the regulator - just put your finger on the thermistor and the fan will start rotating again. Thus, when the radiator temperature is equal to room temperature, the fan does not spin, but as soon as it rises even a little, it will immediately begin to cool.