How to make tubes for quick soldering of wires from ordinary heat shrink

How to connect wires quickly, reliably and without a soldering iron? For example, in a car. You can, of course, use regular twisting in combination with heat-shrink tubing, but this method will not be reliable. Now I will show you how to make a self-soldering tube for soldering wires from a regular piece of heat shrink. A soldering iron is not needed for the connection; a regular gas burner will suffice.

Of course, such tubes are already being manufactured (https://home.washerhouse.com/en/5004-innovacionnyj-sposob-soedinit-dva-provoda.html) and are available for sale on AliExpress - .

But I decided to make my own, since I usually needed them very urgently and had no time to wait for them.

Will need

- Tubular solder spool with flux 0.7 mm thick.

- Heat-shrinkable tubes of the diameter you need (it all depends on what wires you are going to connect in the future).

Making a blowpipe

We take tubular solder, the flux is in the center and sealed along the entire length (if anyone didn’t know).

Flatten a small piece of sandpaper using a hammer.

We take the heat shrink tube and try it to the thickness of a screwdriver.Must walk freely.

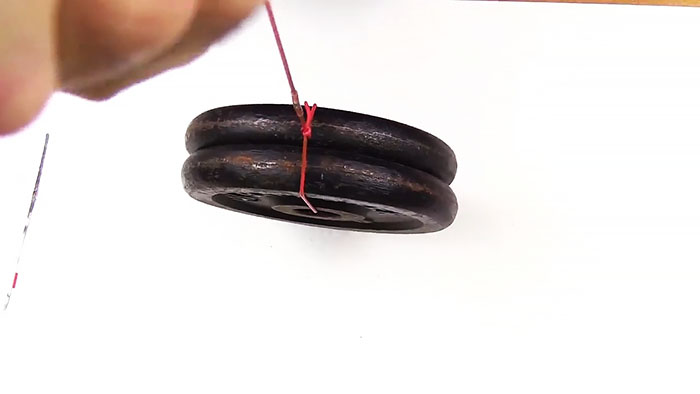

We screw a strip of solder onto this screwdriver.

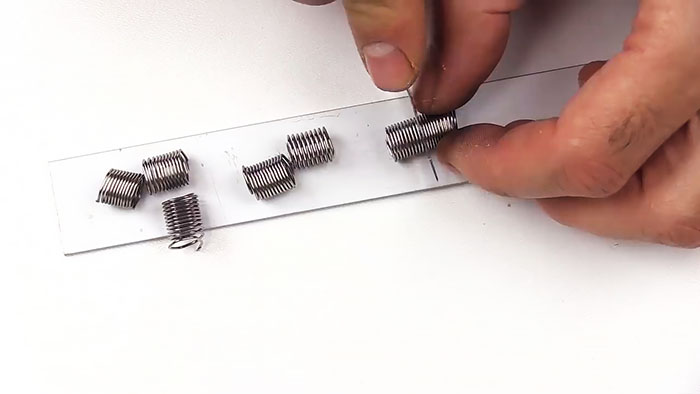

Cut into small pieces.

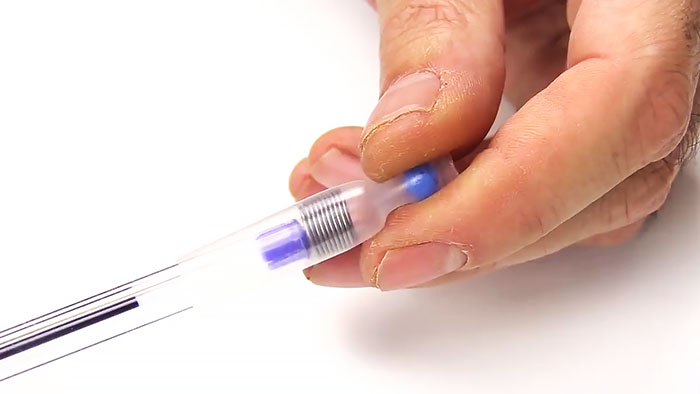

We insert the pieces into the heat shrink in the middle, pushing them with the same screwdriver. Everything should fit tightly so that nothing falls out when carried anywhere.

The drinking tube is ready!

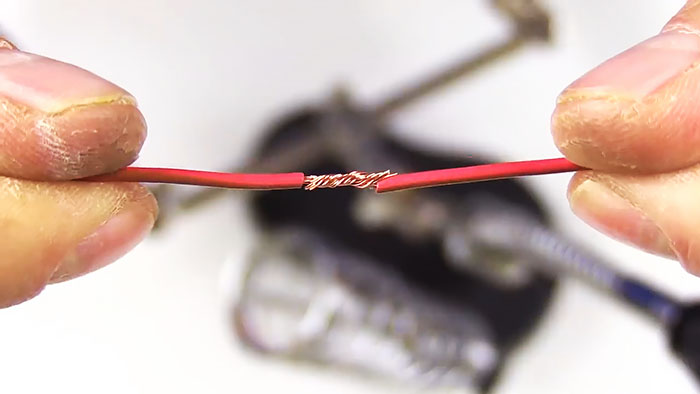

Let's try it. We take two wires and twist the ends.

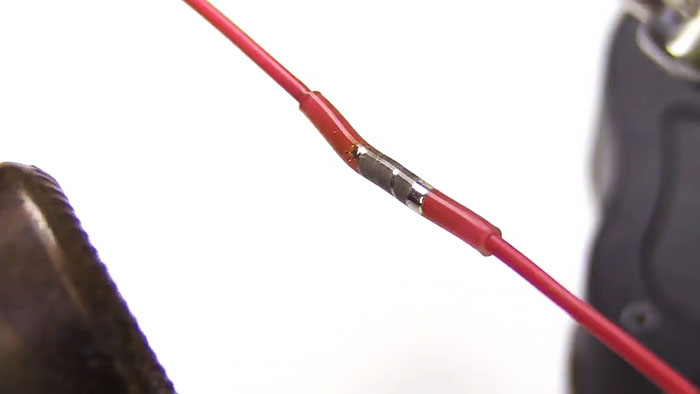

We put on the drinking tube and blow it with a hairdryer.

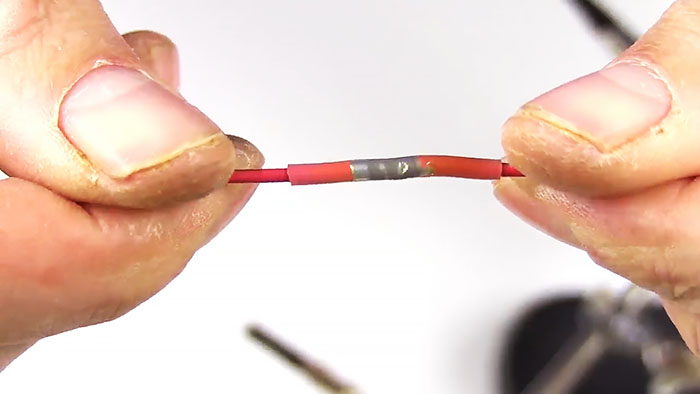

The wires were perfectly soldered inside.

Holds the load wonderfully.

The wire itself is more likely to break than this connection.

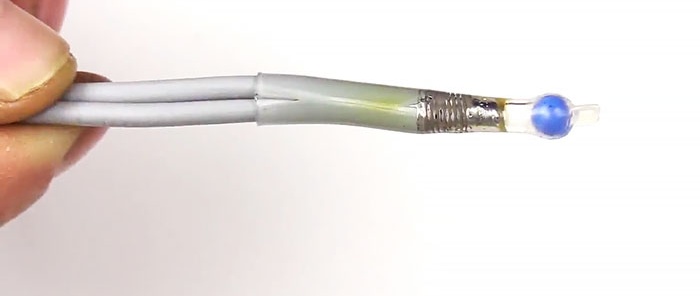

Homemade blowpipe - option number two

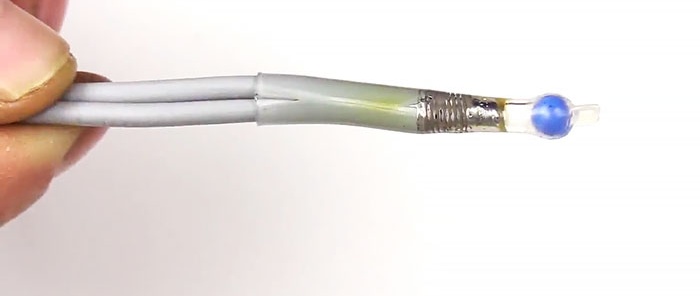

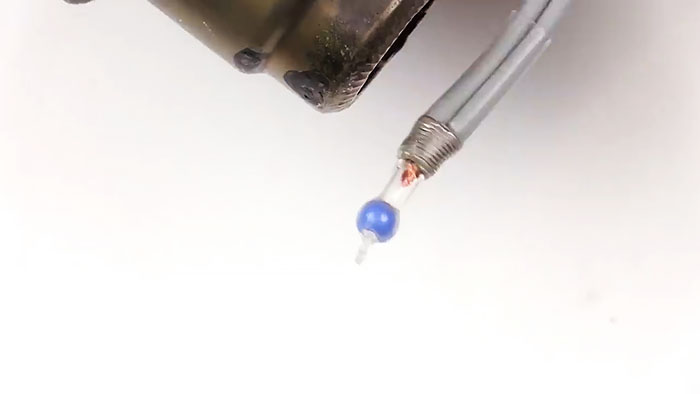

The second option is for connecting two wires running together. We take heat shrink, heat one end so that it shrinks a little. We insert a bead, ball, or a bullet from a children's pneumatic gun and blow the end with a hot air gun.

Only the end, so that you get a tube plugged at one end.

Take a ballpoint pen and roll the tubular solder.

Cut into small curls.

We insert it into the tube almost all the way.

Ready! Tests.

We twist the wires and insert them into the connector.

Use a lighter or hot air gun to heat it up.

The solder melted and the wires were soldered inside.

This is such a useful thing.

Watch the video

Watch this video and other useful tips for soldering electronics.

Similar master classes

How to perfectly solder a wire without a soldering iron

Twisting of wires without soldering that cannot be broken

An innovative way to connect two wires

The most reliable connection of wires without a soldering iron

The strongest connection of large cross-section wires without thickening

How to Protect Your iPhone Charging Cord

Particularly interesting

Comments (4)