Solder sleeves are your salvation when you can’t use a soldering iron

Soldering wires is a difficult skill that not everyone can do. To solder well, you need practice and no rush. There is an alternative very simple and faster way to connect wires using special heat-shrink sleeves with low-temperature solder. Let's consider how to use them in order to obtain no less reliable splicing of cores than with classical soldering.

Materials and tools:

- stripper or sharp knife;

- mounting hair dryer;

- heat shrink sleeves with solder - buy on Ali Express. It’s better to buy a set right away; it’s not expensive, but it’ll definitely fit around the house.

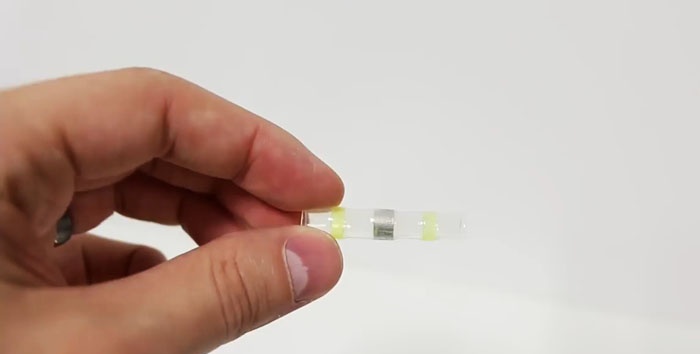

The sleeves used for joining are similar in properties to conventional heat shrink. They are transparent, so they allow you to visually monitor the quality of the connection. There are 3 rings inside the tube. The outer ones are made of hot melt glue, and the central one is made of low-temperature solder with flux.

How to use solder sleeves

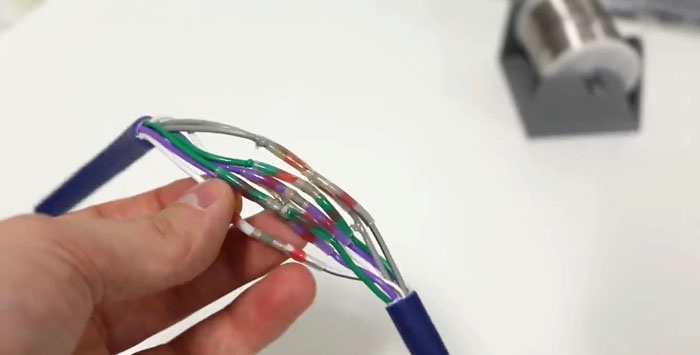

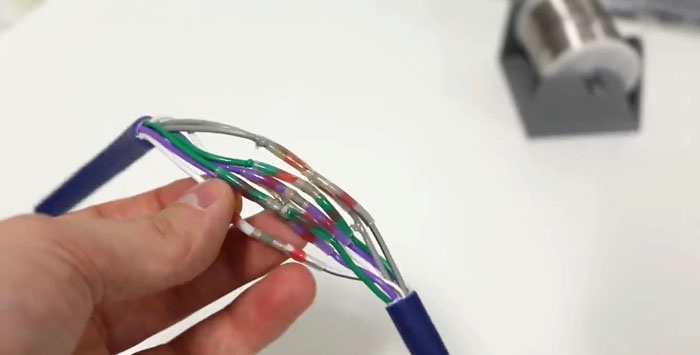

The insulation is removed from the connected stranded conductors using a stripper or knife. It is enough to expose 10 mm.A solder sleeve is threaded onto one of the wires, after which the wires on both wires need to be fluffed up and joined.

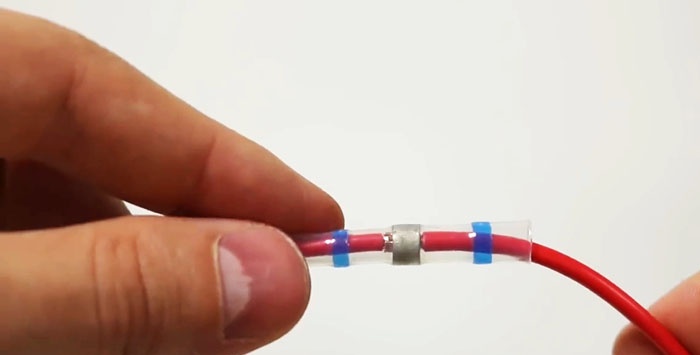

Next, the sleeve is shifted to the splice site so that the solder ring is in the center of the bare wires. The tube is placed under the air stream of a hair dryer turned on at minimum power. It contracts when exposed to heat. You need to plant them in a row from the edge, not from the center.

The hot-melt adhesive rings are heated together with the tube. They will stick, so they will completely prevent any movement or penetration of air and moisture into the joint. The hair dryer needs to be held on the central ring of solder for the longest time. The hot air will first soften and compress the sleeve, and then melt and spread between the core wires. As a result, the connection by soldering will occur not only from above, but also inside the overhanging conductors.

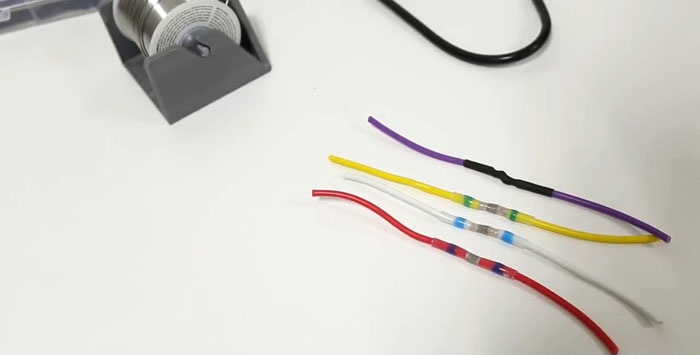

The use of such tubes allows you to splice the cores faster, while using only a hair dryer. This method is also suitable for connecting multi-core wires, so it can be used not only on home or car wiring, but also on industrial facilities.

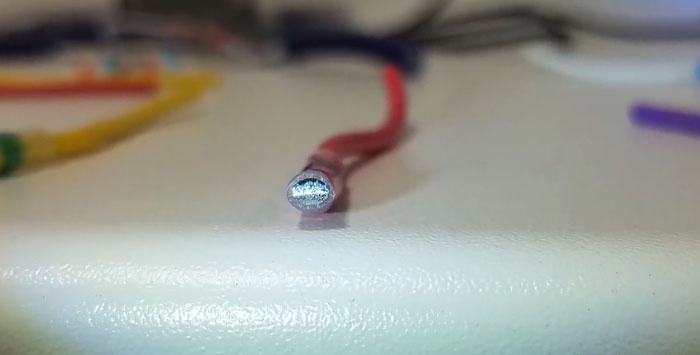

The resulting connection cannot be broken by hand. The wires are more likely to break somewhere else than at the solder. You can verify the reliability of the splice by cutting the test solder. Inside it you can see that there is solder between each core wire. This eliminates heating of the connection under load.

Watch the video

Similar master classes

The strongest connection of large cross-section wires without thickening

The most reliable connection of wires without a soldering iron

An innovative way to connect two wires

How to simply solder aluminum tightly with regular solder

The three most reliable ways to connect wires in

How to make tubes for quick soldering of wires from ordinary

Particularly interesting

Comments (0)