Selection of a working capacitor for a three-phase electric motor

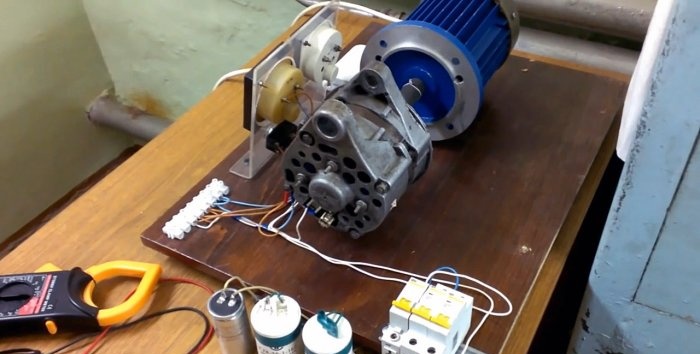

To answer the question of how to choose a capacitor for asynchronous motors and how capacitors differ from each other, we will assemble a stand from a conventional three-phase motor with a power of 250 W. As a load we use a standard generator from a VAZ car.

Let's connect three different capacitors through the machines. Turning on/off the machines will make it possible to check the capabilities of the capacitors.

Selecting a capacitor

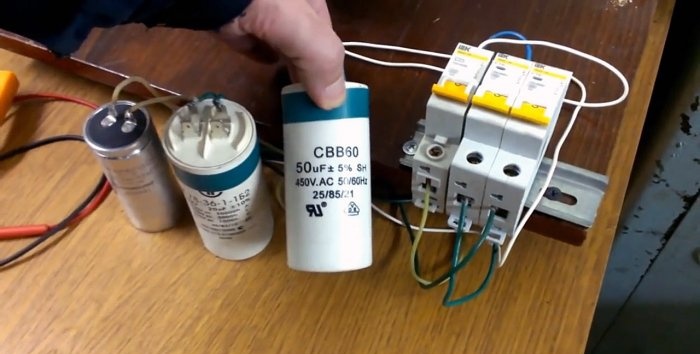

For the experiment, we will select three capacitors with capacities of 10, 20 and 50 microfarads. Our task is to try to start the electric motor from each capacitor in turn.

10 µF capacitor

When connected to a 220 V network and the first capacitor with a capacity of 10 microfarads is turned on, the electric motor turns on only after a push by hand. There is no automatic start.

Conclusion: for a 250 W electric motor, a capacitor capacity of 10 microfarads is not enough.

20 µF capacitor

When you try to start an electric motor from a capacitor with a capacity of 20 microfarads, the motor starts up automatically.

Conclusion: with a capacitor capacity of 20 microfarads, the electric motor started without problems.

50 µF capacitor

When continuing the experiment with a capacitor with a capacity of 50 microfarads, the electric motor starts automatically, but operates with a high noise level and simply shakes.

Conclusion: The capacitance of the last tested capacitor is large for the installed electric motor.

When selecting a capacitor for a low-power three-phase electric motor, give preference to a device with a rated capacitance (as in our experiment) corresponding to the motor power. A small capacitor does not start the electric motor; a capacitor that is too large causes the motor to heat up and make a lot of noise during operation. A capacitor with a capacity of 20 microfarads proved to be optimal in the experiment; it immediately started the engine and did not cause it to overheat.

Conclusion

To start a three-phase electric motor in a 220 V network, the working capacitor is selected based on the engine power. With an increase in power for every 100 W, the capacity should increase by 7-10 microfarads. For example, for a 0.5 kW motor, you can select a capacitor with a capacity in the range of 35-50 μF.

You also need to take into account such a parameter as the rated voltage of the device (that is, the voltage that the capacitor can withstand). It is recommended to use capacitors with parameters that are 100% higher than the actual voltage applied to the device. For this example it is 450 V.

Watch detailed video

Similar master classes

Starting a three-phase motor from a single-phase network without a capacitor

How to check the starting capacitor

Connecting a three-phase electric motor to a single-phase network

Connecting a three-phase motor according to a star and delta circuit

How to start a stepper motor without electronics

Simple power supply with adjustable voltage

Particularly interesting

Comments (9)