Simple brush with metal bristles

Many craftsmen consider the presence of such a brush to be a relic of the past, preferring modern tools. However, a real specialist understands the real advantages of such a product and always keeps it at hand. At the same time, some operations require brushes with specific parameters of both the shape itself and the bristles. Therefore, you can very often see that craftsmen have so many such products in their tools.

Advantages of a brush with metal bristles

Such brushes have certain advantages even over modern tools:

- low cost and ease of self-production;

- light weight, allowing for long operations;

- does not require mains power and does not require batteries;

- does not take up much space;

- allows you to work in hard-to-reach places.

Today, such brushes are very rarely found in stores. At the same time, their cost is higher than the real one. Therefore, experienced craftsmen prefer to make such a tool themselves. This allows you to select a specific type of bristle, set its density, bristles length and handle shape.For this you will need a small wooden block, a metal cable of the required rigidity and a metal plate.

Making a brush

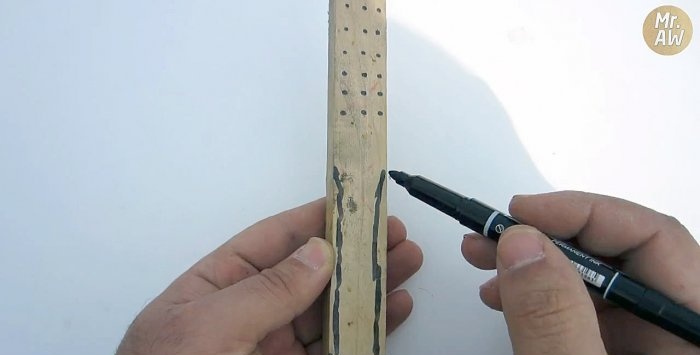

First we need a wooden block.

Any type of wood will do, but hardwood is preferred. We apply markings to the block, outlining the dimensions of the handle. On the other edge of the workpiece we mark holes for installing bristles. There must be an even number of them, since we will use pairs.

Important! Before starting work, it is recommended to create a sketch of the workpiece in a 1:1 size. If you have an old tool of this type, then you can use its dimensions as a basis.

At the next stage, we drill holes according to the markings and grind the handle. We use a drill and a grinder for this.

Important! The diameter of the drill must correspond to the diameter of the cable used for the bristles.

We will make the bristles from rope. We need to cut it into equal parts, corresponding in number to half the holes. The length of the cut should be two lengths of bristles + 3 cm.

Example! If you need to get a brush with 2 cm bristles, then the length of the cable section should be 7 cm.

We insert the finished pieces into the holes using the staple principle. Occupying two cells in one piece. We align each segment, creating a semblance of bristles on one side of the workpiece.

Next, we clamp the block in a vice, and using a hammer, we straighten the bend of the cables.

Attention! At this moment, it is important to control that future villi do not move. Otherwise, the brush will have bristles of different lengths.

At the next stage, we cut out a plate from sheet metal that corresponds to the dimensions of the rear part of our workpiece. This way we get a kind of lint retainer.

We install the plate on the product, securing it with nails.

We process the brush with a grinder to remove burrs and splinters. The finished product should not only be comfortable, but also safe.

Using pliers or round nose pliers, slightly untwist the wire in each cable, creating metal bristles.

The brush is ready for use.

Watch the video

Similar master classes

Particularly interesting

Comments (2)