Brush made from plastic bottles

Household brush with a wooden handle and bristles made from plastic bottle strips. I won’t say that the whole process is simple, but it’s not particularly complicated either. So anyone can repeat it if they want. This is a regular brush that can be used to clean your work area after work.

To make one piece I needed about seven plastic bottles.

The process of making brushes from plastic bottles

Cut off the necks of the bottles. All you need is the straight cylindrical part of the bottle.

We cut bottles into ribbons using any method. I use this one with a homemade jig.

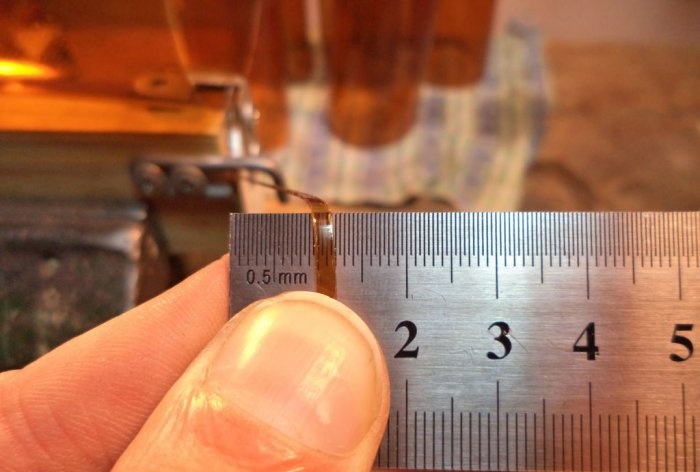

Larger view. The main cutter is a blade from a stationery knife.

The width of the tape is ultimately about two millimeters or slightly thicker.

Cut ribbons from bottles, with the ends secured so they don't mix.

Next, I will need two more homemade devices. These are the rollers for belt tension:

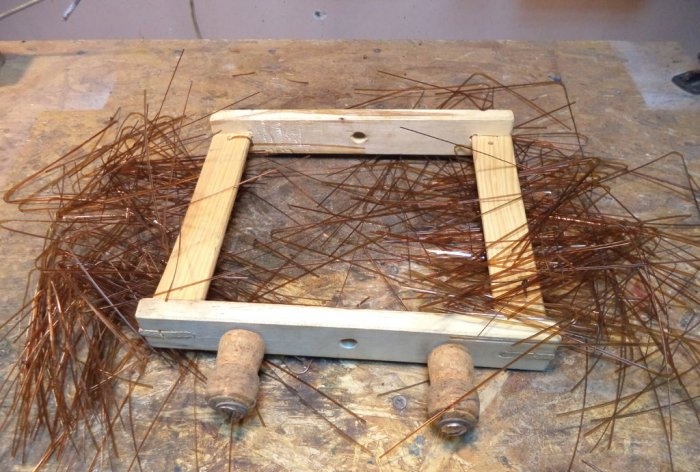

And the frame for winding the tape:

With these things you need to make a tight winding.

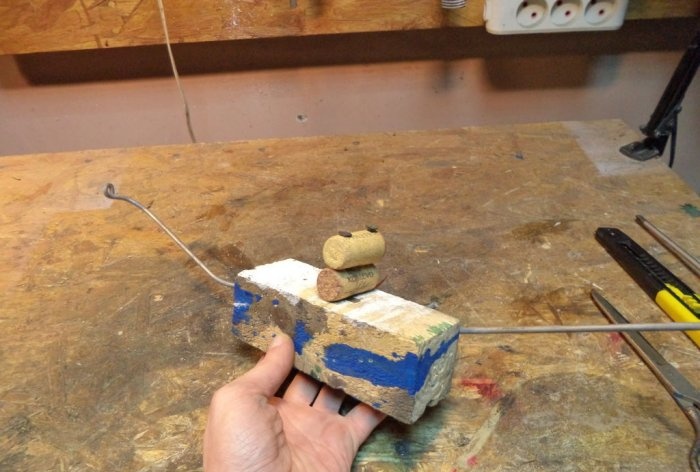

Tension rollers are two wine corks twisted with self-tapping screws to a block.

To avoid holding and pulling the tape with my hands, I use this device.Yes, and pulling the tape with your hands, you know, is fraught with danger, you can easily get cut off.

We clamp the rollers in a vice and pass the tape through them.

Preparing the rotation frame for the frame.

We put on the frame.

We begin winding by securing the first end of the tape.

We wind with medium force.

All bottles are wound.

If you unwind this ribbon now, it will again take the form of curls. To prevent this from happening and for the tape to remain in the shape of the frame, it must be heat treated.

You can do this in several ways:

- Immerse in boiling water.

- Blow with hot air from a hair dryer.

- Heat in the oven.

I will use an electric grill heater. I put a winding there.

I carry out temperature control for several minutes so as not to melt the tape. Everything should be in moderation.

We take it out and cut the entire winding exactly in the middle.

The segments retained their form of winding on the frame - which is what we need.

We collect all the segments.

Now we prepare the frame for the brush. We take two cheeks of a suitable size.

Shave it a little to make it even.

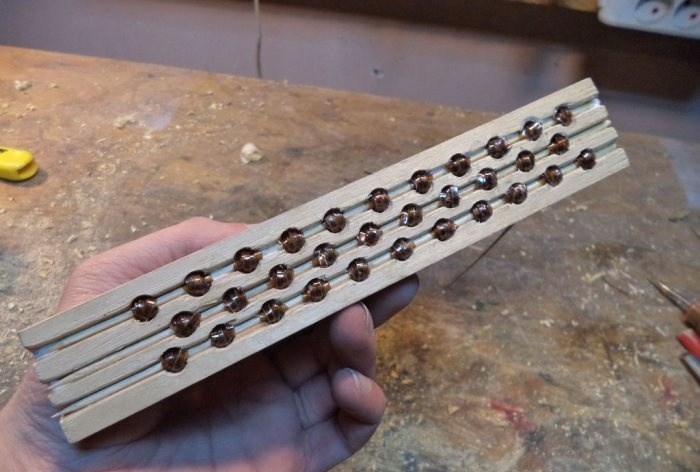

We mark the holes in a checkerboard pattern for future bristles. Three rows in total.

We drill holes. Small in diameter at first.

Then the big one. Bad experience. Where would we be without him?

Let's try again:

Like this:

We make longitudinal cuts with a hacksaw.

Clean the groove with sandpaper.

I will use regular cooking skewers to secure the bristle brushes.

We adjust the grooves; the skewers won’t fit.

Preparing the brushes.

We take the amount that fits tightly into the hole.

We collect a row and insert a skewer.

We stretch everything down as far as it will go, having previously smeared it with wood glue.

All three rows of brushes are ready.

Everything is coated with glue.

Apply even more glue to the entire plane.

Now we glue the brushes to the handle.We clamp it in a vice and leave it to dry.

The brush took on its usual shape.

Using round files or other equipment:

We make smooth edges for a smooth transition.

We sand and make the entire surface smooth.

Drill a hole in the handle.

We fix the bristles between two bars.

Using a sharp knife, cut to level.

And now, the brush made from plastic bottles is ready!

The finished brush was soaked in boiled linseed oil.

Watch the video

The brush does its job perfectly.

Original article in English

Similar master classes

Particularly interesting

Comments (5)