How to remove a broken screw

There are such unforeseen situations when a self-tapping screw breaks off. This can happen if you screw it too hard, or simply over time it can rust and lose its strength. Often the breakage occurs near the head of the screw, while the main body remains in the wood.

If the design of the connection allows you to move the screw slightly to the side, then this is not a problem, but what if you need to screw the new one exactly in the same place? For example, in a door hinge, what to do in this case? There is always a way out. The matter, of course, is not entirely pleasant, but quite fixable.

Will need

- Telescopic antenna tube.

- A metal rod along the inner diameter of a piece of tube.

- Scalpel.

- Screwdriver.

- Chisel.

- PVA glue

Removing the broken screw

So, the first thing you need to do is find a tube whose internal diameter will be greater than the diameter of the stuck fragment of the screw. We disassemble any antenna from an old receiver and take out one elbow. Now this stuff is in abundance everywhere, there shouldn’t be a shortage.

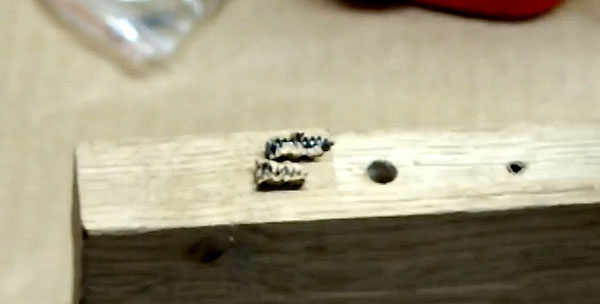

We will make a special tool from this piece to extract the fragment.To do this, one end of the tube must be trimmed with a file to a flat surface, and then made sharp with a scalpel, cutting the edge in a circle at an angle.

The other end of the tube must be clamped into the screwdriver chuck, but this cannot be done easily, since it will simply be compressed when tightened. To avoid this, you need to insert a metal rod into it, which will prevent the tube from flattening.

We clamp it into the cartridge.

Now we rest against the fragment and drill it out along with the tree.

We drill until the wood around the fragment breaks off on its own and in the end it will be possible to simply remove the fragment.

Instead of a fragment, there was a smooth and beautiful hole.

Now, as you probably guessed, you need to glue a wooden cap into the resulting hole. We drip glue and spread it evenly throughout the hole.

Next we stuff the cap, the tighter the better.

We cut off the protruding excess with a sharp chisel evenly.

That's all the repairs. Now we place the loop in place and make a mark with an awl in the center of the hole.

We screw the new screw into place.

As you can see, everything fell into place, the product became fully functional and regained its original appearance and functionality.

Watch the video

Similar master classes

Particularly interesting

Comments (1)