How to Make an Effective Wire Stripper

If there is a large volume of work with electrical wires (replacing lines, repairs, etc.), you cannot do without a special device for exposing the ends of the wiring. There are special mechanisms that facilitate this labor-intensive process, but few people know that in five minutes, practically from improvised means, you can make a simple and effective device for cleaning cables of different diameters (from 10 mm and less).

What you need to have on hand

- A piece of plastic pipe for wiring installation (outer diameter 20 mm);

- Large blade from a stationery knife (width 16 mm);

- Plugs from the installation box (2 pcs.);

- Among the tools we will need a drill with a set of drills for metal (wood), a saw, a sharp knife, sandpaper, a tape measure, a marker and a vice.

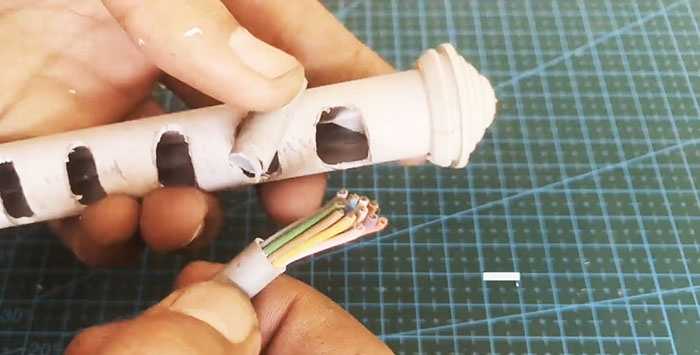

Preparing the knife holder

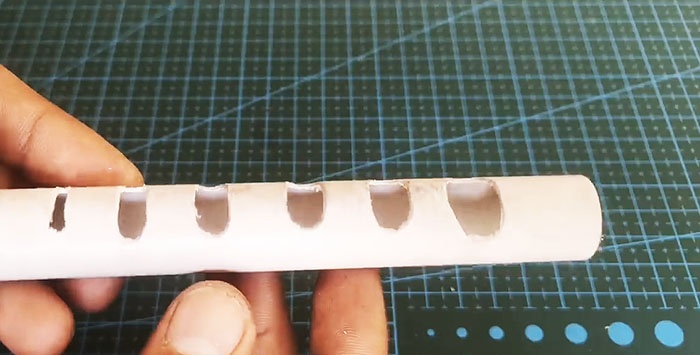

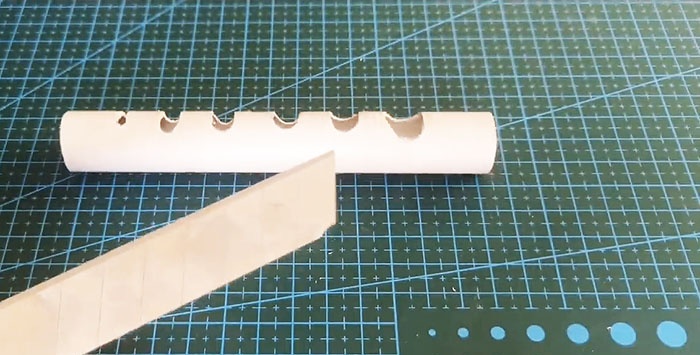

To begin, cut off a piece of pipe 14 cm long. Using sandpaper and a sharp knife, remove burrs from the cut. We apply markings to the pipe at intervals of 2 cm so that we have 6 marks.

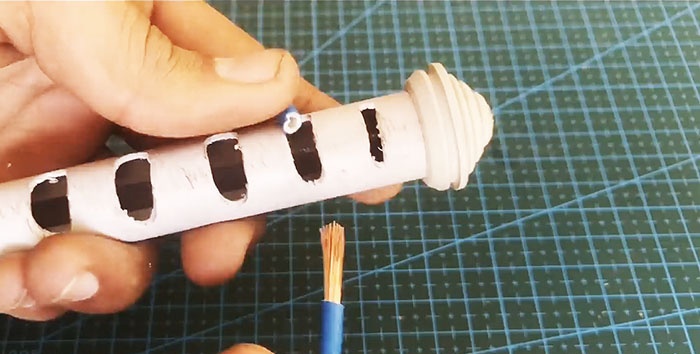

We will need drills with a diameter of 10, 8, 6, 5, 4 and 2 mm. We start with a larger diameter.Clamping the drill in the chuck and the pipe in a vice (with the marks facing up), we make a cut in the pipe, pressing the rotating drill with its side in the center of the mark and performing reciprocating movements.

The immersion depth of the drill should not be greater than its thickness. The resulting oval-shaped holes should be cleaned of plastic residues using a knife.

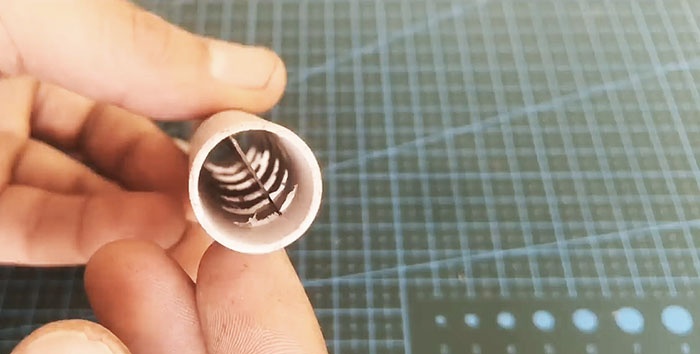

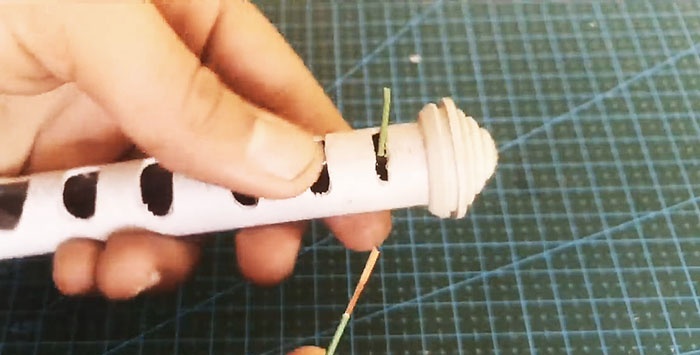

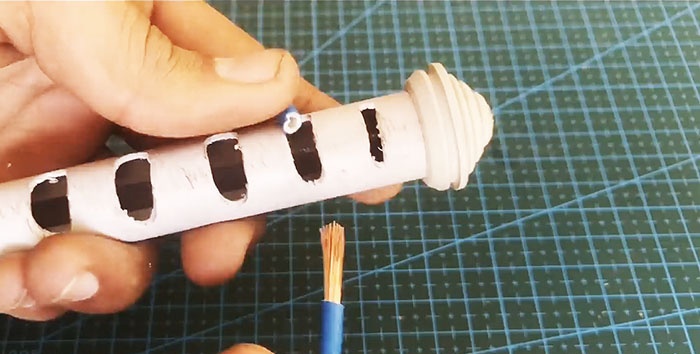

Blade insert

The blade must be inserted into the pipe so that the cutting edge is located strictly in the middle of all holes. It enters with very great force (and we need to insert it completely), so to facilitate the process, we need to use the other hand to squeeze the pipe from the sides, parallel to the plane of the blade, as much as possible, while simultaneously pushing it inward.

After that, we install plugs from the distribution box on the edges of the pipe and everything is ready. Tests can be carried out.

How to properly use a homemade insulation stripper

The groove that best matches the cable diameter is selected. The wire itself is laid directly into it so that the knife line is in the place where the insulation should be removed.

At this point, the wire is pressed with a finger against the inner blade and the wire is rotated in a circular motion in any direction. The depth of cut can be adjusted by pressing your finger. Then, holding the wire in the recess with the same finger, with the other hand you should pull it in the direction opposite to the device and release the end from the insulation.

The device copes well with multi-core communications, is easy to use and does not require any maintenance. If the cutting sharpness is lost, the blade can be replaced with a new one.

When performing work, you should follow the rules for safe work with power tools, and also be especially careful when installing a thin blade - it is very easy to cut yourself with it.

As you can see, it is not at all necessary to spend money on special devices when you can get an equally effective device for stripping the ends of wiring with your own hands almost free of charge.

Watch the video

Similar master classes

How to make a shaped vegetable knife from a piece of PVC pipe

Cable reel from a plastic canister

How to easily make a twisted harness for laying wires

Cases made of plastic pipes

No worse than the factory one: Knife handle made of polypropylene pipe

6 useful screwdriver attachments that few people know about

Particularly interesting

Comments (6)