LUT technology

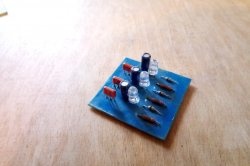

Recently, radio amateurs are increasingly using this technology to create boards for amateur radio designs. This technology is distinguished by its simplicity and reliability.

DIY LUT technology

First, we prepare a template for the future board.

The board, which is created using special board drawing programs, first needs to adjust the brightness and contrast. The template should have maximum brightness. Once the board is ready, we begin printing. It is advisable to print several templates on one A4 sheet.

After the board template is ready, you need to cut it off from the general sheet.

Next, we prepare foil fiberglass or getinax, clean the surface and cut it to the size of our board.

Turn on the iron and wait a couple of minutes until the iron warms up.

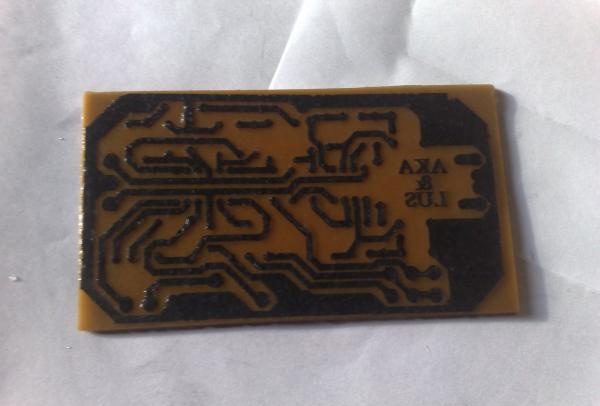

Next, carefully attach the paper template with the pattern to the board, the board pattern facing the foil!

Next, we begin to iron, making sure that the template adheres evenly to the foil. You need to iron for 3 minutes, carefully over the entire board, pay strict attention to the edges of the board.

After finishing, let the textolite cool for 5 minutes.

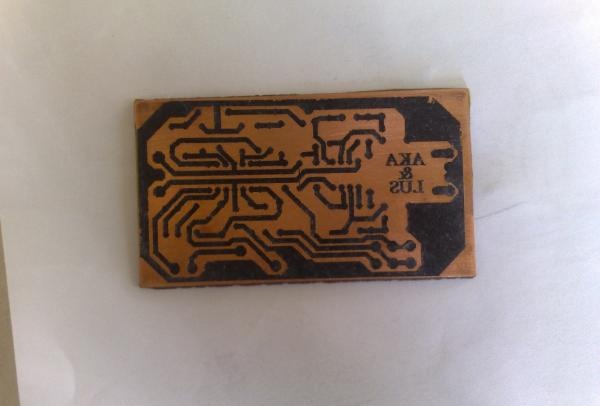

After cooling, take a vessel with water and rinse your board. In the end, we get a clear portrait of the board on the surface of the foil fiberglass laminate.

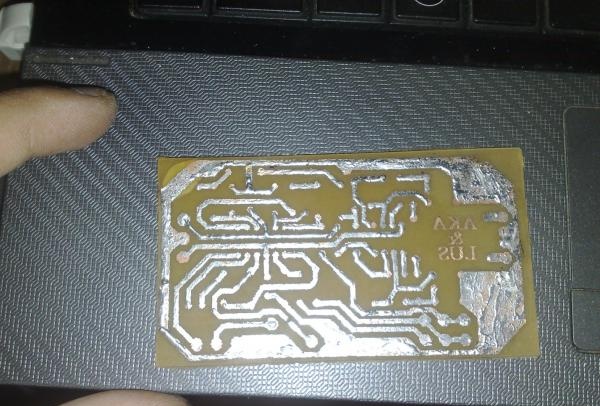

For etching, I use a non-traditional method, which is not very often used among radio amateurs. For etching chemistry, we need 100 mg of hydrogen peroxide (3% peroxide solution), two packs of citric acid (40 g each pack) and one teaspoon of table salt.

Mix everything together and mix thoroughly until the salt and citric acid are completely dissolved.

We immerse the board in the solution, it is advisable to place the vessel with the solution in the sun, this speeds up the etching process.

Small boards (boards of bugs, multivibrators, etc.) are etched in 20-30 minutes.

One such solution is enough to etch more than 10 small circuit boards.

Similar master classes

Particularly interesting