Resistance welding using one supercapacitor

Surely, when working with batteries to replace them, you needed resistance welding. Since it is very undesirable to solder lithium-ion batteries with regular solder, there is a danger of overheating. Buying or making expensive equipment for two or three cases is definitely not profitable and costly. But such a resistance welding machine is available to absolutely everyone. After all, it essentially consists of just one part, called a supercapacitor.

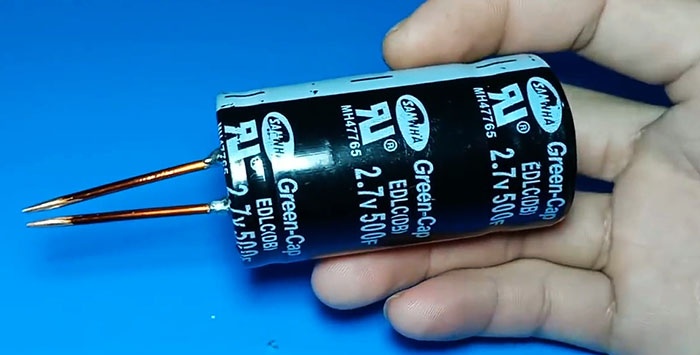

This is almost the same capacitor, only with a high capacity. Having all the same advantages as a regular capacitor.

Will need

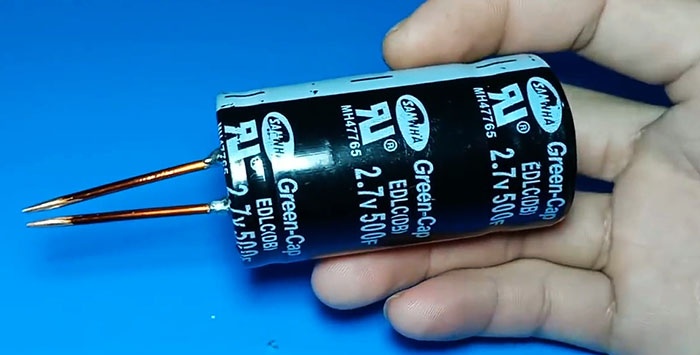

- Supercapacitor (ionistor) with a voltage of 2.7 V and a capacity of 500 F.

- Thick wire, with a cross-section of at least 2 square meters. mm.

Making a simple resistance welding machine from a supercapacitor

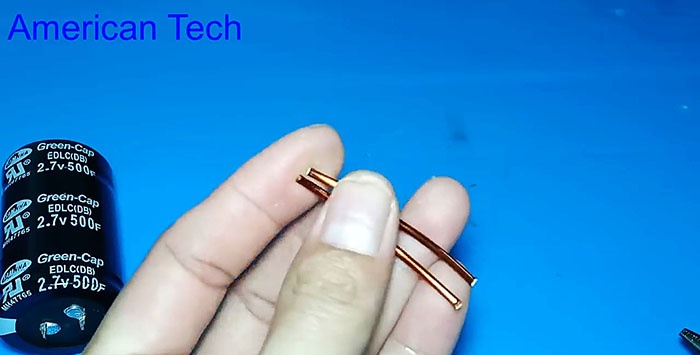

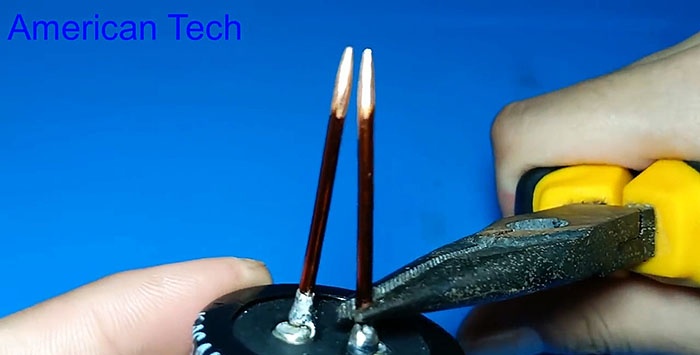

We unwind the skein of wire and cut off two identical pieces 5-7 cm long.

We straighten them with wire cutters or pliers so that they are very even. Now, on one side of each segment, we clean the edge with a file, removing the varnish insulation.

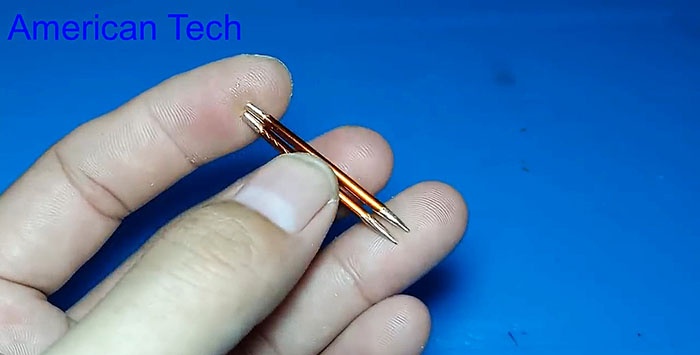

And on the other side we make a point.

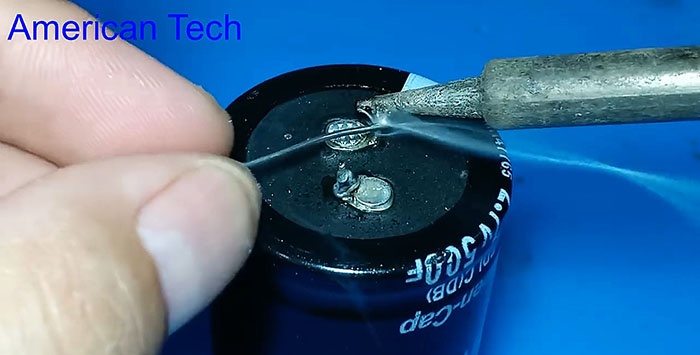

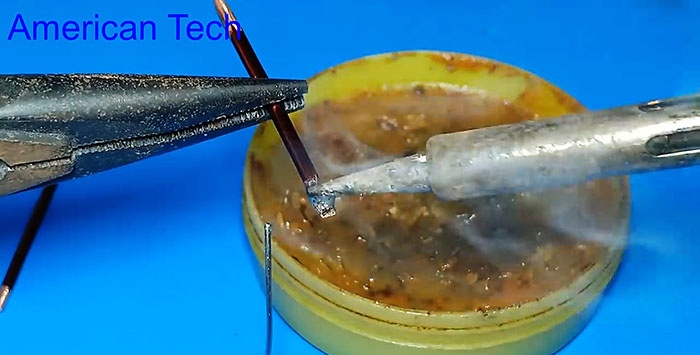

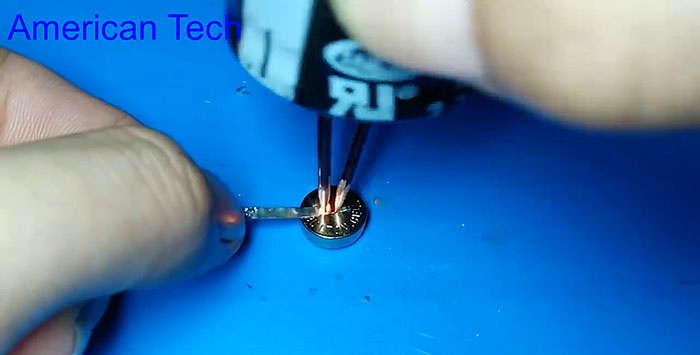

Tinking contacts ionistor.

We tin the bare and blunt ends of pieces of copper wire.

Solder the pieces to the contacts of the supercapacitor.

The resistance welding machine is completely ready!

All that remains is to bend the leads with wire cutters so that there is a minimum distance between the tips of 2-3 mm.

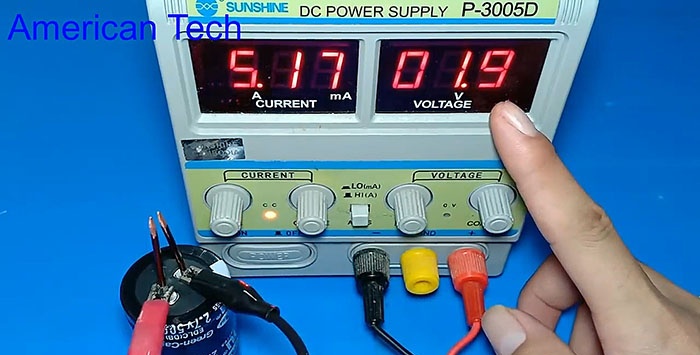

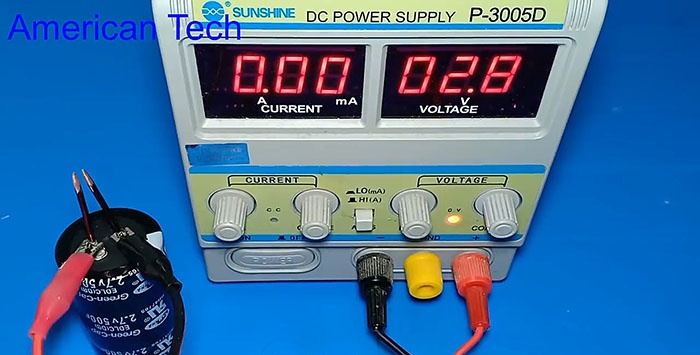

We charge with a current of 5 A.

The voltage should not exceed 2.7 V. Although, as you can see in the photo, mine is one tenth more. This is certainly not critical, but it’s better not to risk it.

Charging lasted approximately 15 minutes.

contact welding

Now let's figure out how to weld. Since our apparatus is incredibly simple, it cannot regulate the length of the pulses. The whole task thus falls on you. Therefore, exposure will have to be done intuitively.

Here is an example of how to solder a metal strip to a battery. Place the strip on the battery. Now we bring the contacts of the device and thereby quickly close it.

We hold it for about 0.5 seconds and quickly remove it so as not to burn out the connection.

Everything was welded perfectly.

It is better not to weld the first time - be sure to practice.

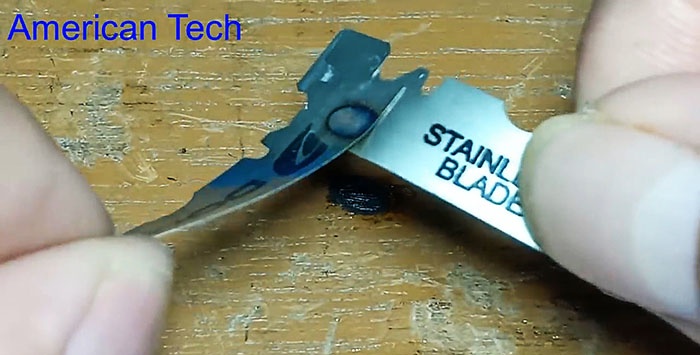

Weld the blade:

Everything is secure and will definitely not fall off. Place the main emphasis on training, and then everything will go like clockwork. One charge ionistor enough for a dozen of these welds.

Watch the video

Similar master classes

Particularly interesting

Comments (9)