How to make a garden auger from a saw blade

A good tool is highly valued in dacha farming. And since the work takes place mainly on the ground, today we will talk about a simple device that facilitates excavation work. With it you can make holes for potatoes, plant trees, or install posts for a new fence.

This homemade product is notable for the fact that it is used for its manufacture. Namely, an unnecessary disk for cutting wood, with a diameter of 18-25 cm. These are used for circular saws, small universal machines and grinders (angle grinders). The presence of pobedite soldering on it is not necessary.

The rod, or more precisely the shaft, for a garden auger is designed to be fixed in a standard drill or screwdriver chuck, so its thickness should not exceed 13 mm. A calibrated rod or threaded tie will do. You will also need several pieces of metal pipes that fit into one another. We will fasten all the parts using electric welding. So let's get started!

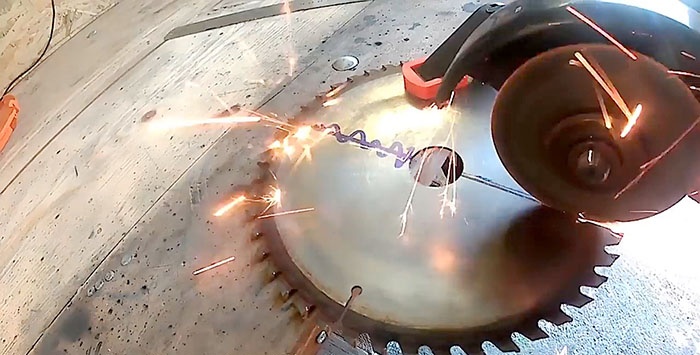

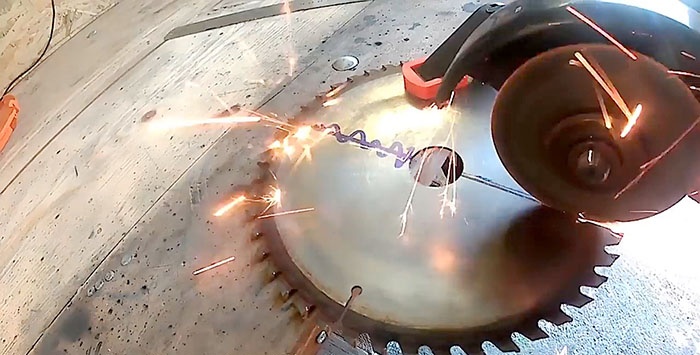

We mark the disk into two equal parts. Along this line, using an angle grinder, we make a through slot from the center to the edge.

The metal of the disk is elastic, and even if you hold it in a vice and try to bend it with a lever, this is unlikely to work.

You will have to heat the slot area with a gas burner, since heated metal is easier to deform.

We bend the disk slightly by hand, giving it the shape of a drill.

Discs for cutting wood have a seat hole located in the center. Usually it is 16-32 mm. The diameter of our rod is smaller, so we need to solve the problem of securing the drill to it. From the scraps of metal pipes, we select those that fit into one another, and we make short sleeves from them, 4-5 cm long.

We align the sleeves in the center of the disk, and place it on a support so that it is strictly in a horizontal projection. We weld their connection using electric welding.

Then you can insert the rod inside the sleeve and also scald it, slightly extending the end from the disk by 5-6 cm.

After cooling the welding area in a bucket of water, clamp the device in a vice and sharpen its end with a grinder. It will serve as a guide during drilling.

For more productive operation of the tool, we sharpen the drill. We refine it with a file.

That's all, our garden drill is ready!

We insert the rod into the chuck and select the slowest gear on the screwdriver gearbox.

And we go to our garden to drill holes.

Now you can replant any seedlings, etc. without any problems.

If you decide to work with such a device manually, you will need to weld a transverse handle, about 30-40 cm long, onto the end of the rod for good leverage.

It is not necessary to use a wood cutting disc for the auger. For those who don’t have such unnecessary things in their household, you can cut a circle out of ordinary metal. In this case, you don’t even need to heat it with a burner.

Well, in conclusion, if such a tool is painted to protect it from corrosion and rust, it will serve you for decades, because there is practically nothing to break in it.

Will need

This homemade product is notable for the fact that it is used for its manufacture. Namely, an unnecessary disk for cutting wood, with a diameter of 18-25 cm. These are used for circular saws, small universal machines and grinders (angle grinders). The presence of pobedite soldering on it is not necessary.

The rod, or more precisely the shaft, for a garden auger is designed to be fixed in a standard drill or screwdriver chuck, so its thickness should not exceed 13 mm. A calibrated rod or threaded tie will do. You will also need several pieces of metal pipes that fit into one another. We will fasten all the parts using electric welding. So let's get started!

Step-by-step instructions for making a garden auger

We mark the disk into two equal parts. Along this line, using an angle grinder, we make a through slot from the center to the edge.

The metal of the disk is elastic, and even if you hold it in a vice and try to bend it with a lever, this is unlikely to work.

You will have to heat the slot area with a gas burner, since heated metal is easier to deform.

We bend the disk slightly by hand, giving it the shape of a drill.

Discs for cutting wood have a seat hole located in the center. Usually it is 16-32 mm. The diameter of our rod is smaller, so we need to solve the problem of securing the drill to it. From the scraps of metal pipes, we select those that fit into one another, and we make short sleeves from them, 4-5 cm long.

We align the sleeves in the center of the disk, and place it on a support so that it is strictly in a horizontal projection. We weld their connection using electric welding.

Then you can insert the rod inside the sleeve and also scald it, slightly extending the end from the disk by 5-6 cm.

After cooling the welding area in a bucket of water, clamp the device in a vice and sharpen its end with a grinder. It will serve as a guide during drilling.

For more productive operation of the tool, we sharpen the drill. We refine it with a file.

That's all, our garden drill is ready!

We insert the rod into the chuck and select the slowest gear on the screwdriver gearbox.

And we go to our garden to drill holes.

Now you can replant any seedlings, etc. without any problems.

Practical advice

If you decide to work with such a device manually, you will need to weld a transverse handle, about 30-40 cm long, onto the end of the rod for good leverage.

It is not necessary to use a wood cutting disc for the auger. For those who don’t have such unnecessary things in their household, you can cut a circle out of ordinary metal. In this case, you don’t even need to heat it with a burner.

Well, in conclusion, if such a tool is painted to protect it from corrosion and rust, it will serve you for decades, because there is practically nothing to break in it.

Watch the video

Similar master classes

Particularly interesting

Comments (4)