Mini circular table based on drill

When making small crafts from wood, you need to evenly spread the boards and slats, which can be done on a circular table. For the average craftsman, this is an unnecessary tool that takes up a lot of space. An excellent alternative would be to make a compact circular saw driven by a drill.

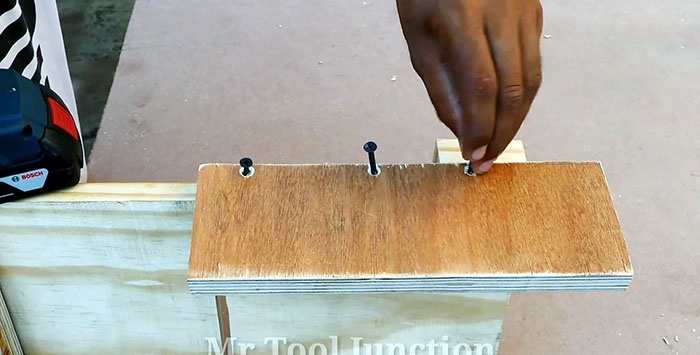

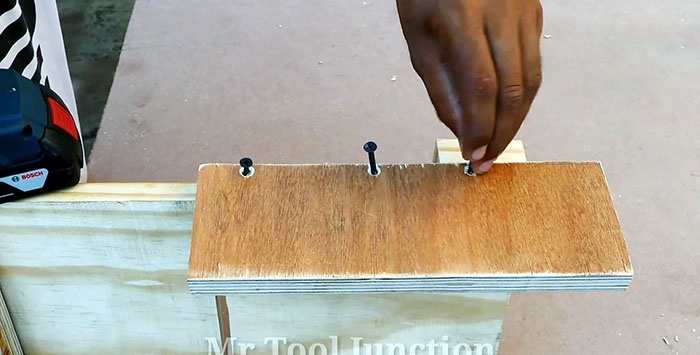

On the base of the circular machine, legs are installed from a board or shield 40x20 cm. They use scraps of slats. They are screwed into the corners with a pair of self-tapping screws.

To make a stop for attaching the drill, you need to screw a strip of plywood with an extension from a scrap board to the edge of the base. You can simply make a similar structure from a sawed-off strip.

A transverse cutout is made in the center of the shield for the saw blade. To do this, holes are first drilled along its edges, and then they are connected with a double cut.

To secure the machine tabletop, a piece of plywood is screwed onto the side of the base.Its height is selected individually according to the diameter of the saw wheel. A pair of door hinges are attached to it.

Between the cutout for the saw blade and the extension, a hole is drilled to fit the diameter of the drill handle. A sawn-off handle is inserted into it and screwed with self-tapping screws.

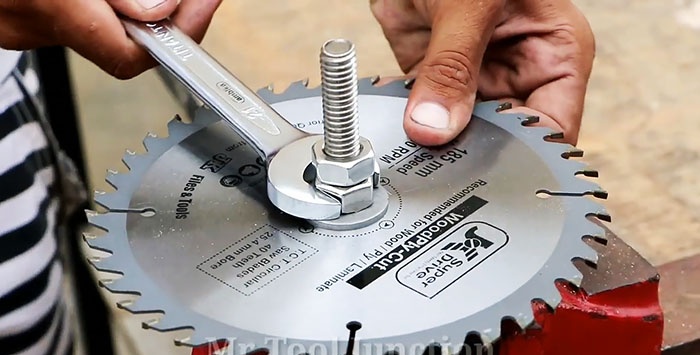

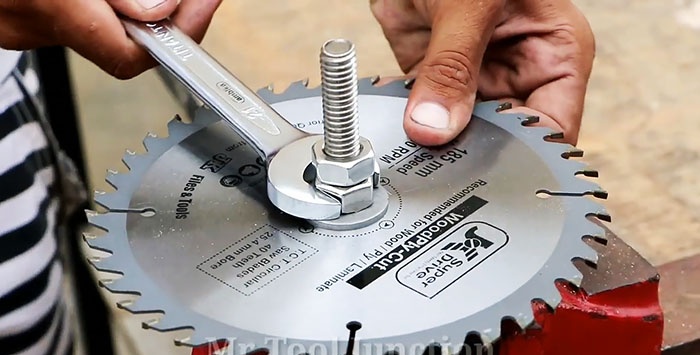

For further assembly you need to install a saw blade. To do this, put a bearing on the M12 bolt, put a circle, a washer and 2 nuts. The drill is installed in a fixed handle. A circle is clamped in its chuck.

A cross-bar made of plywood must be installed on the table frame. A hole is drilled in it for the diameter of the bearing so that it fits in with force. It will serve as an additional mount for the disk and support for the table top.

Next, a plywood table top is installed. It attaches to door hinges. Afterwards, the drill starts and the tabletop is lowered onto the saw blade. He will cut a window for himself.

If the tabletop partially covers the drill, then it is better to cut it in such a place so that the tool cools properly. You also need to make cutouts on it to secure the parallel stop from the rail.

The resulting circular table, despite the low speed of the disk rotation, can quite help when cutting laminate flooring. They are convenient for cutting small workpieces, for example, for assembling stools or drawers.

Materials:

- board or furniture board 20 mm 40x20 cm;

- rail 50x30 mm;

- self-tapping screws;

- plywood 10 mm;

- door hinges – 2 pcs.;

- bolt M12;

- bearing;

- M12 washer;

- nuts M12 – 2 pcs.;

- M8 bolts with nuts – 2 pcs.

Assembling a circular table

On the base of the circular machine, legs are installed from a board or shield 40x20 cm. They use scraps of slats. They are screwed into the corners with a pair of self-tapping screws.

To make a stop for attaching the drill, you need to screw a strip of plywood with an extension from a scrap board to the edge of the base. You can simply make a similar structure from a sawed-off strip.

A transverse cutout is made in the center of the shield for the saw blade. To do this, holes are first drilled along its edges, and then they are connected with a double cut.

To secure the machine tabletop, a piece of plywood is screwed onto the side of the base.Its height is selected individually according to the diameter of the saw wheel. A pair of door hinges are attached to it.

Between the cutout for the saw blade and the extension, a hole is drilled to fit the diameter of the drill handle. A sawn-off handle is inserted into it and screwed with self-tapping screws.

For further assembly you need to install a saw blade. To do this, put a bearing on the M12 bolt, put a circle, a washer and 2 nuts. The drill is installed in a fixed handle. A circle is clamped in its chuck.

A cross-bar made of plywood must be installed on the table frame. A hole is drilled in it for the diameter of the bearing so that it fits in with force. It will serve as an additional mount for the disk and support for the table top.

Next, a plywood table top is installed. It attaches to door hinges. Afterwards, the drill starts and the tabletop is lowered onto the saw blade. He will cut a window for himself.

If the tabletop partially covers the drill, then it is better to cut it in such a place so that the tool cools properly. You also need to make cutouts on it to secure the parallel stop from the rail.

The resulting circular table, despite the low speed of the disk rotation, can quite help when cutting laminate flooring. They are convenient for cutting small workpieces, for example, for assembling stools or drawers.

Watch the video

Similar master classes

Particularly interesting

Comments (0)