Drill extension using friction welding

A lathe is a multifunctional piece of equipment that can be used to perform a variety of tasks, including precision friction welding of parts. This can be useful if you need to extend a drill or other tool. When welding a drill using conventional welding, it is impossible to correctly center the shank, therefore, when using such equipment, strong runout is observed. If the extension is carried out on a lathe by friction, then this problem is almost eliminated.

Equipment, materials and tools:

- lathe;

- drill chuck for tailstock;

- drill;

- rod for extending the shank;

- cutter.

Friction welding drill

The first step is to select a rod of the same diameter as the drill shank. Before welding, the end of the workpiece must be leveled. It is clamped in the machine spindle and ground with a cutter. The drill itself has a smooth shank end, so it does not require preparation.

A drill with a shank exit of approximately 15 mm is clamped into the spindle.

A drill chuck is installed on the tailstock of the machine, in which a rod for extension is fixed.

To perform friction welding and not damage the machine, it is better to set the speed to approximately 60-70% of the maximum possible. Now you can turn on the spindle rotation.

After starting the machine, you need to slowly push the quill, connecting the shank of the drill and the end of the extension rod.

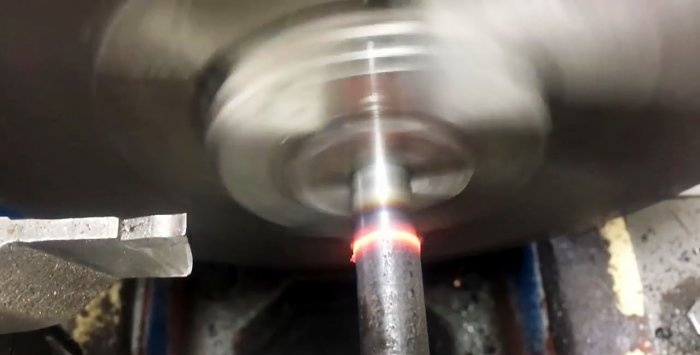

The pressed parts will begin to rub in.

At first there will be slight bowing and beating, accompanied by chips flying out, but after a few seconds it will stop.

As the quill with the rod moves towards the shank, the friction force increases, which leads to strong heating of the parts.

When the metal splits until a plastic mass is obtained at the point of friction, the machine must be stopped. At the last moment it is important to push the quill a little more. Molten steel from two parts is boiled together, resulting in welding.

If an elongated drill is needed to make a deep hole, then the fungus at the splice site must be ground off using a cutter.

Otherwise, the thickening will not fit into the drilled hole. However, grinding off the fungus will reduce the reliability of the fastening, since the welding area is reduced.

When extending on a lathe, it will not be possible to completely avoid runout of the elongated drill, but it will be acceptable for performing everyday tasks. To achieve reliable welding, it is important to warm up the workpieces well before turning off the spindle rotation. There is no need to be afraid that the cutting edge of the drill will lose its hardening because it is located quite far from the hot shank.

Watch the video

Similar master classes

Particularly interesting

Comments (0)